Plastic-injection moulding machine

An injection molding machine, an organic technology, applied in the field of plastic injection molding machines, can solve the problems of poor injection dose control and low mold clamping ability, and achieve good safety performance, convenient operation, economical and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

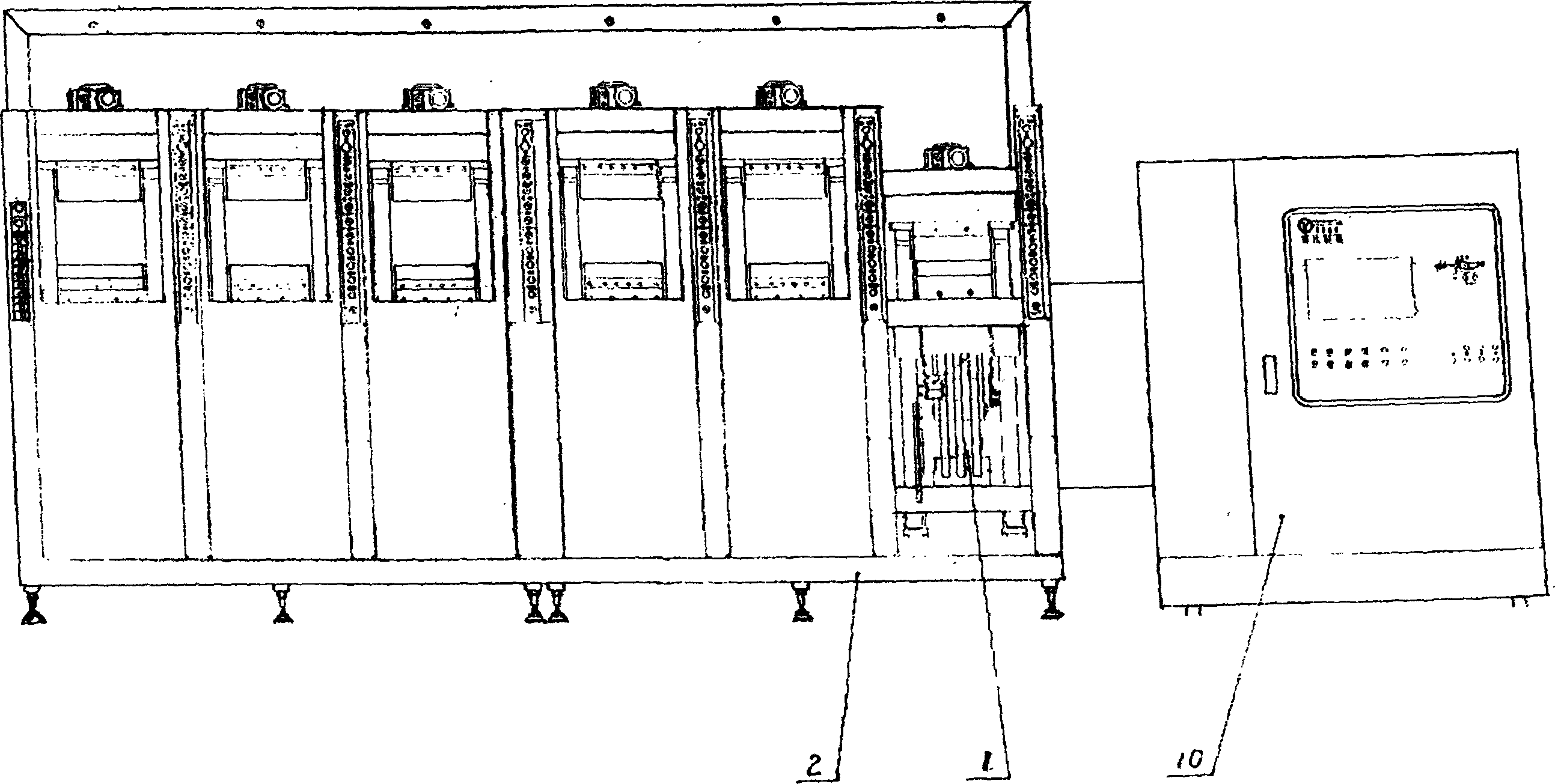

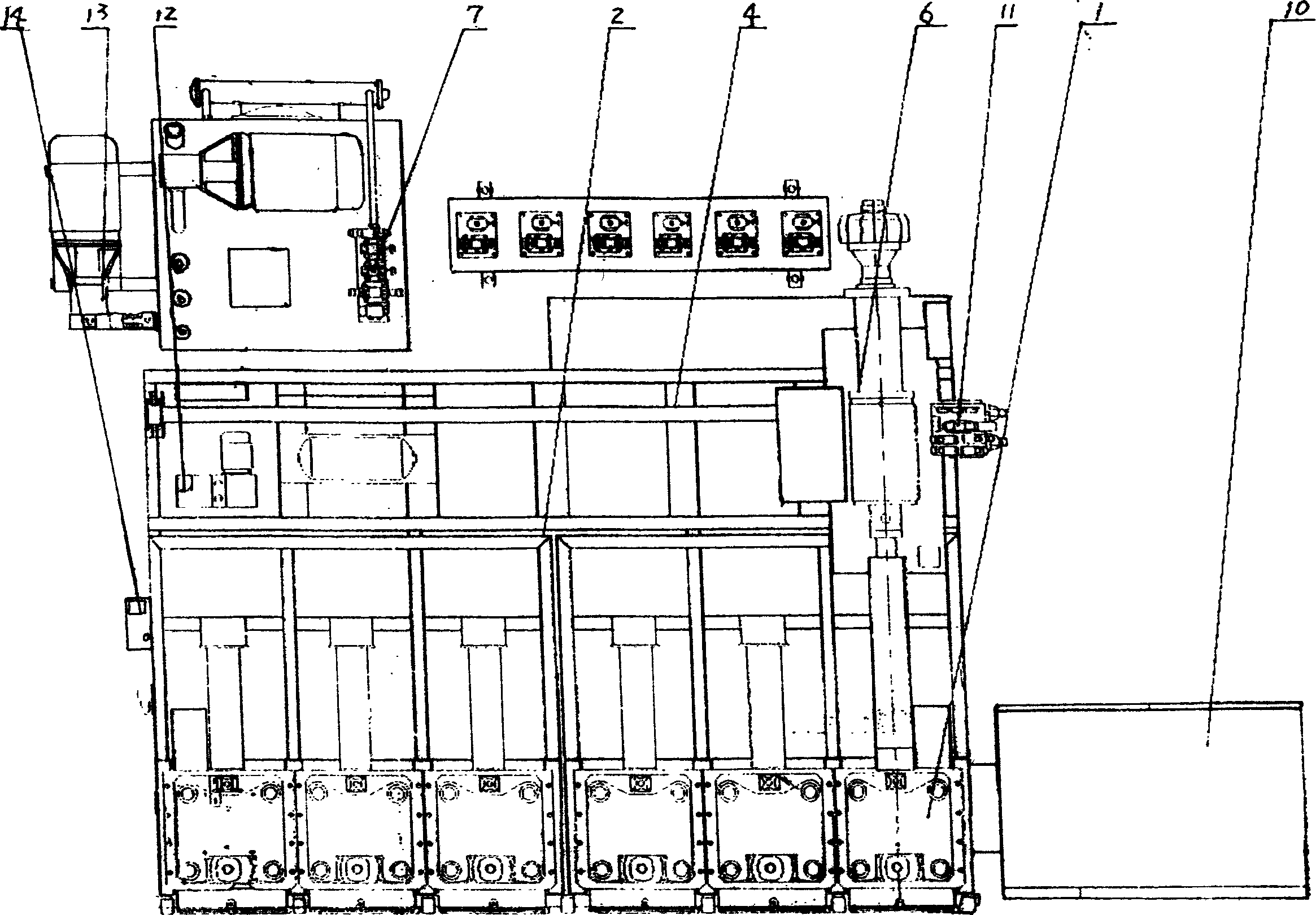

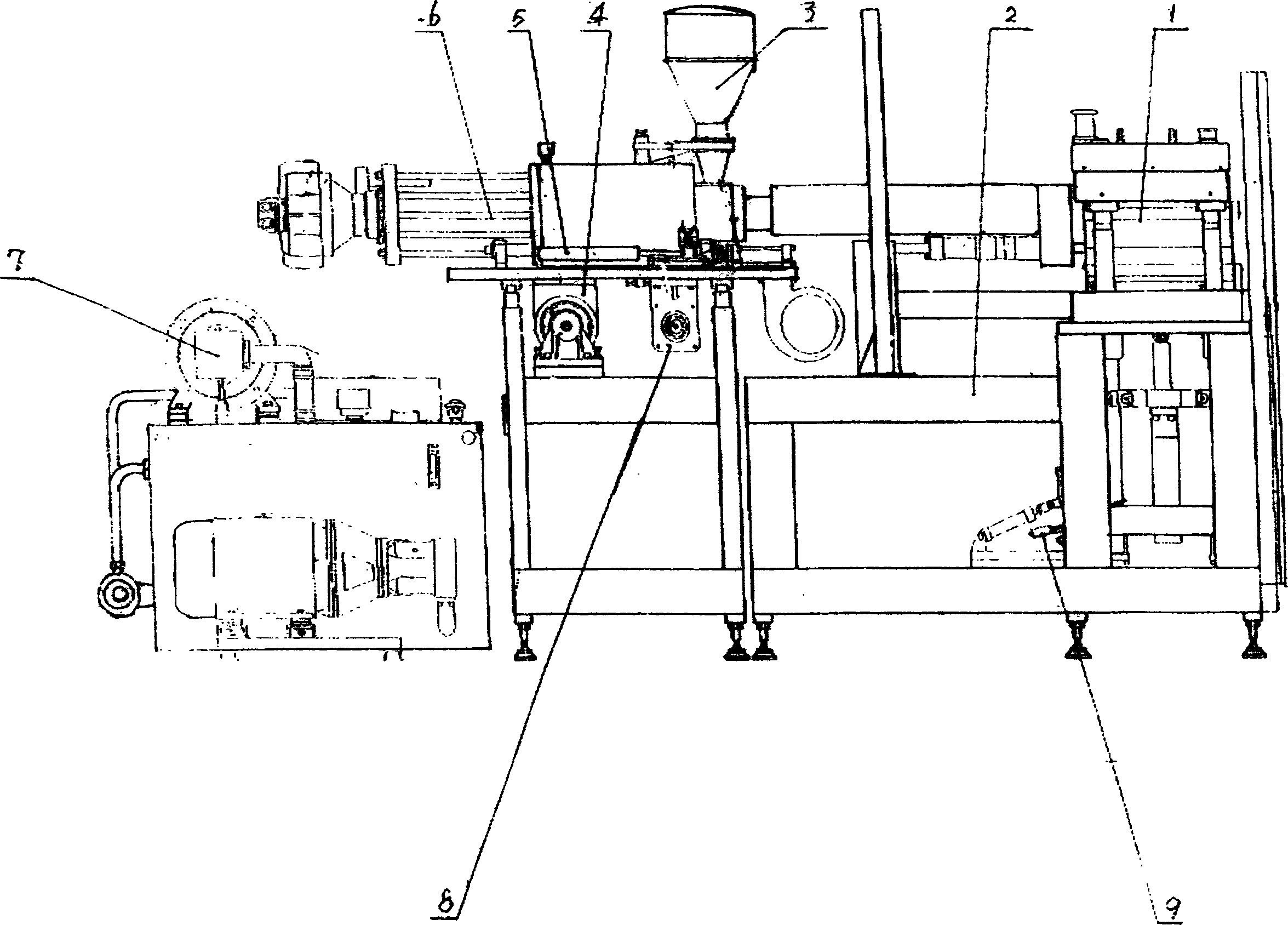

[0016] Further explanation is given below in conjunction with accompanying drawings:

[0017] Such as figure 1 , figure 2 with image 3 As shown, the EVA injection molding machine of the present invention includes a frame 2, an industrial computer 10, a hydraulic mechanism 7, and the frame 2 is provided with a vertical double toggle mold clamping mechanism 1, a ball screw seat shifting mechanism 4, a lubricating mechanism 14 and Vacuum pneumatic mechanism 12, a safety lever mechanism 9 is installed under the vertical double toggle mold clamping structure 1, an injection mechanism 6 is installed above the ball screw seat shifting mechanism 4, and a vacuum feeding dryer 3 is installed above the injection mechanism 6, variable The pump 13 is connected with the motor and fixed on the fuel tank, the proportional servo valve 11 is fixed on the seat shifting plate 26 , and the electronic ruler 5 is fixed on the injection mechanism 6 .

[0018] Such as figure 1 , Figure 4 , F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com