Hollow shaft inner wall polishing and painting device

A hollow shaft and shaft sleeve technology, which is applied to the field of hollow shaft inner wall grinding and painting devices, can solve the problems of inconvenient painting and the unsatisfactory roughness of the inner wall of the hollow shaft, etc., and achieves the effect of simple structure, favorable for long-term preservation and rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

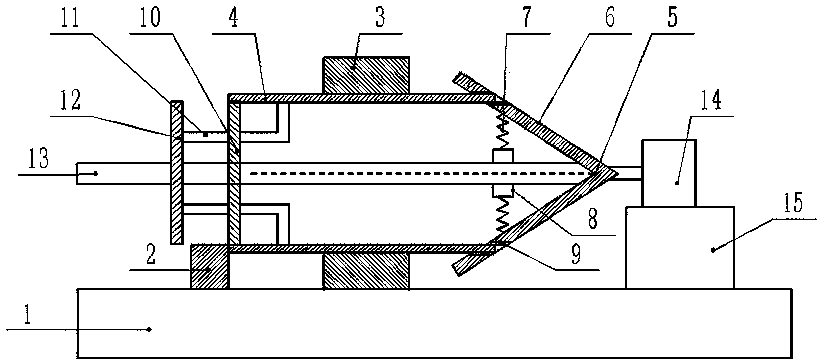

[0021] The reference signs in the drawings of the specification include: base 1, telescopic block 2, shaft sleeve 3, hollow shaft 4, claw 5, claw foot 6, spring 7, fixed block 8, groove 9, scraper 10, connecting Rod 11, paint spraying disc 12, screw mandrel 13, motor 14, supporting platform 15.

[0022] like figure 1 As shown, a hollow shaft inner wall grinding and painting device includes a base 1, the base 1 is arranged horizontally, a vertically telescopic telescopic block 2 is welded on the left side of the base 1, a shaft sleeve 3 is welded on the right side of the base 1, and the hollow shaft 4 passes through the shaft sleeve 3; the screw mandrel 13 passes through the hollow shaft 4, and the left end of the screw mandrel 13 is threadedly connected with a paint spraying disc 12, which is disc-shaped and fits with the inner wall of the hollow shaft 4 with clearance, and the disc has holes. The paint is sprayed out from the hole, and the screw rod 13 on the right side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com