Master batch capable of intelligently regulating temperature and preparation method of master batch

An intelligent temperature regulation and masterbatch technology, applied in the direction of conjugated synthetic polymer man-made filaments, etc., can solve the effect of phase change material phase change temperature, phase change enthalpy value, large influence of polymer masterbatch, and quality change of masterbatch. and other problems, to achieve the effect of easy promotion, small influence of phase change enthalpy, and small process loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of phase-change microcapsules with hydrophobic surface

[0034] Add 10g Span-80 to 100ml cyclohexane to form oil phase solution A;

[0035] Add 3g resorcinol and 5g acetaldehyde in 5g deionized water to form aqueous solution B;

[0036] Mix solution B and 5g polyethylene glycol 1000 evenly and add to solution A, stir to form inverse emulsion C;

[0037] Add 2 g of aniline solution dropwise to emulsion C, heat to 50°C, and react for 30 minutes;

[0038] After the reaction, the method is filtered, washed, separated and dried to form a hydrophobic phase-change microcapsule coated with a benzoxazine resin.

[0039] 2. Blend and granulate the surface hydrophobic phase change microcapsules described in 1 and polypropylene at a mass ratio of 40:60 with a twin-screw extruder at 160-200°C;

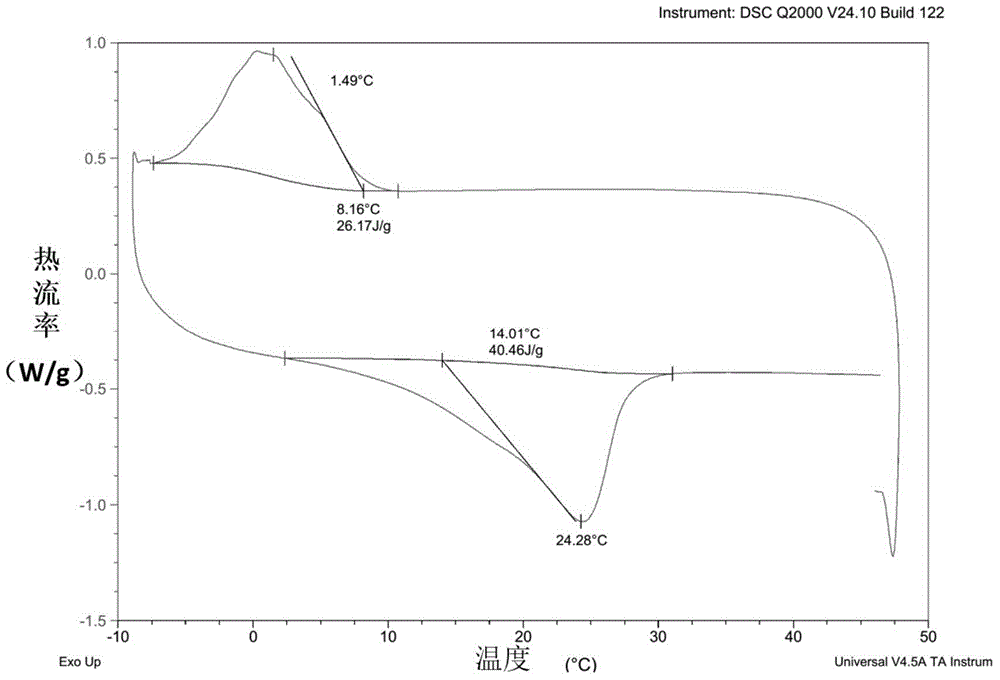

[0040] That is, the intelligent temperature-regulating polypropylene masterbatch of the present invention is obtained. After testing, the DSC characterization curve of the...

Embodiment 2

[0043] 1. Preparation of surface hydrophobic phase change microcapsules:

[0044] In 90ml liquid paraffin, add 5g surfactant Span-80 to form oil phase solution A;

[0045] Add 3 g of anhydrous calcium chloride to 7 g of deionized water to form an aqueous phase solution B;

[0046] Add 5g phenol and 6g acetaldehyde in 6g deionized water to form aqueous phase solution C,

[0047] Slowly add solutions B and C to solution A, stir to form a stable W / O emulsion, heat to 65°C, and react for 4 hours; filter, separate, and dry to obtain surface hydrophobic phase change microcapsules;

[0048] 2. Blend and granulate the surface hydrophobic phase change microcapsules and polybutylene terephthalate described in 1 at a mass ratio of 30:70 with a twin-screw extruder at 260-300°C;

[0049] That is to obtain the intelligent temperature-regulating polyester masterbatch of the present invention.

[0050] The masterbatch is further melt-spun to obtain a kind of intelligent temperature-regulat...

Embodiment 3

[0052] 1. Preparation of surface-hydrophobic phase-change microcapsules:

[0053] Add 10g Span-80 to 80ml n-hexane to form oil phase solution A;

[0054] Add 3g resorcinol and 5g acetaldehyde in 5g deionized water to form aqueous solution B;

[0055] 3 g of polyethylene glycol 1000 and 2 g of polyethylene glycol 2000 were added to 5 g of deionized water to form an aqueous phase solution C;

[0056] Mix solutions B and C evenly and add to solution A, stir to form inverse emulsion D;

[0057] Add 2 g of aniline solution dropwise to emulsion D, heat to 50°C, and react for 30 minutes;

[0058] After the reaction, it is filtered, washed, separated and dried to form a surface hydrophobic phase-change microcapsule coated with phenolic resin.

[0059] 2. The surface hydrophobic phase change microcapsules described in 1 and polyurethane elastomer rubber (TPU) are blended and granulated with a twin-screw extruder at 130-230 °C at a mass ratio of 20:80;

[0060] Promptly obtain the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com