Shielding structure of shielding electric wire

A shielding structure and wire technology, applied in the direction of cable installation, cable joints, electrical components, etc., can solve the problem of reducing the self-sustaining force of the wire, and achieve the effect of enhancing the adsorption force and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

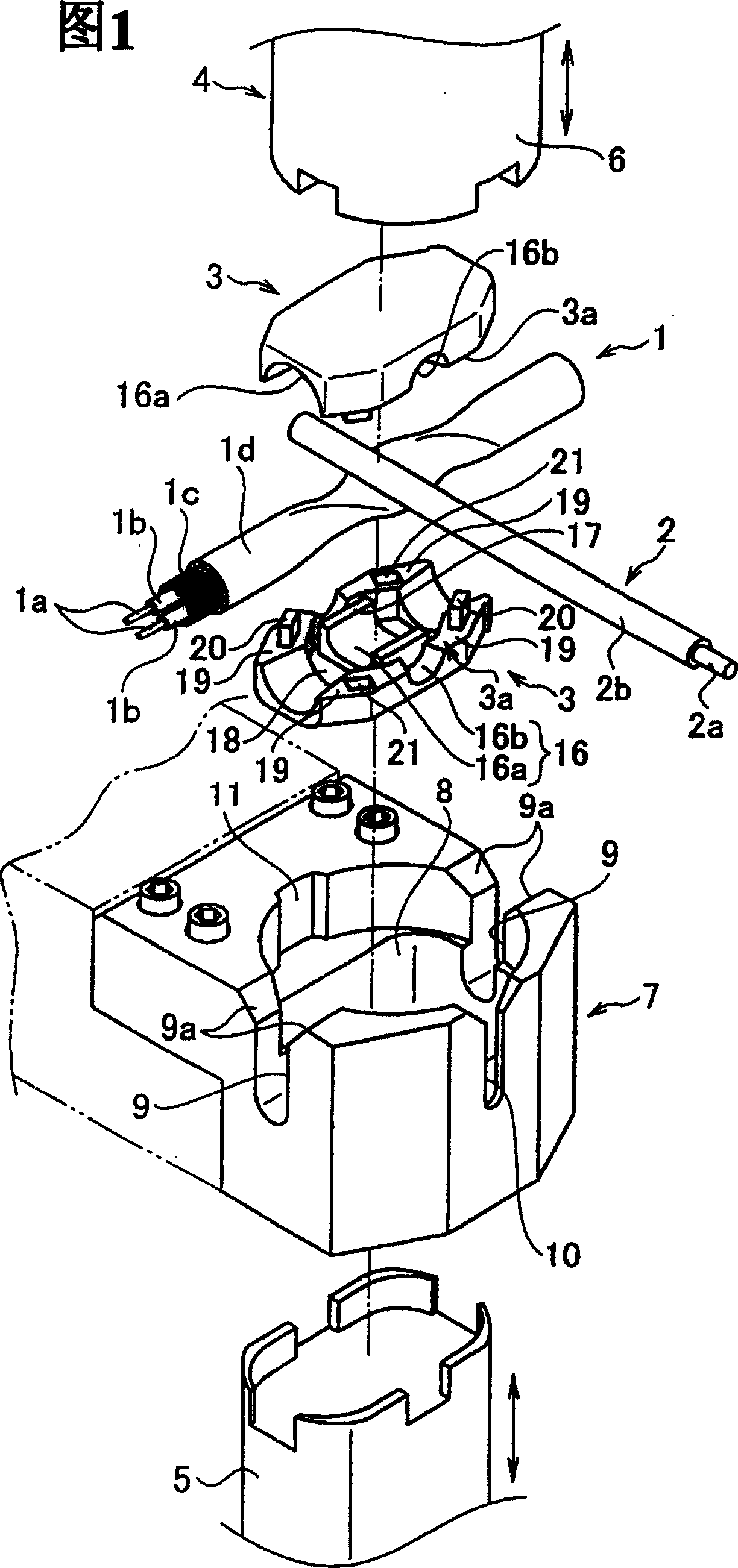

[0067] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0068]As shown in FIG. 1, the shielded electric wire 1 is constituted by two core wires 1a and 1a twisted, insulating inner sheaths 1b and 1b respectively covering the peripheral portions of the core wires 1a and 1a by resin, As shielding members, a braided wire 1c for covering the outer peripheral portions of the insulating inner sheaths 1b and 1b, and an insulating outer sheath 1d formed of a resin material covering the outer peripheral portion of the braided wire 1c.

[0069] The ground wire 2 is constituted by the core wire 2a and an insulating outer sheath 2b formed of a resin material and covering the periphery of the core wire 2a.

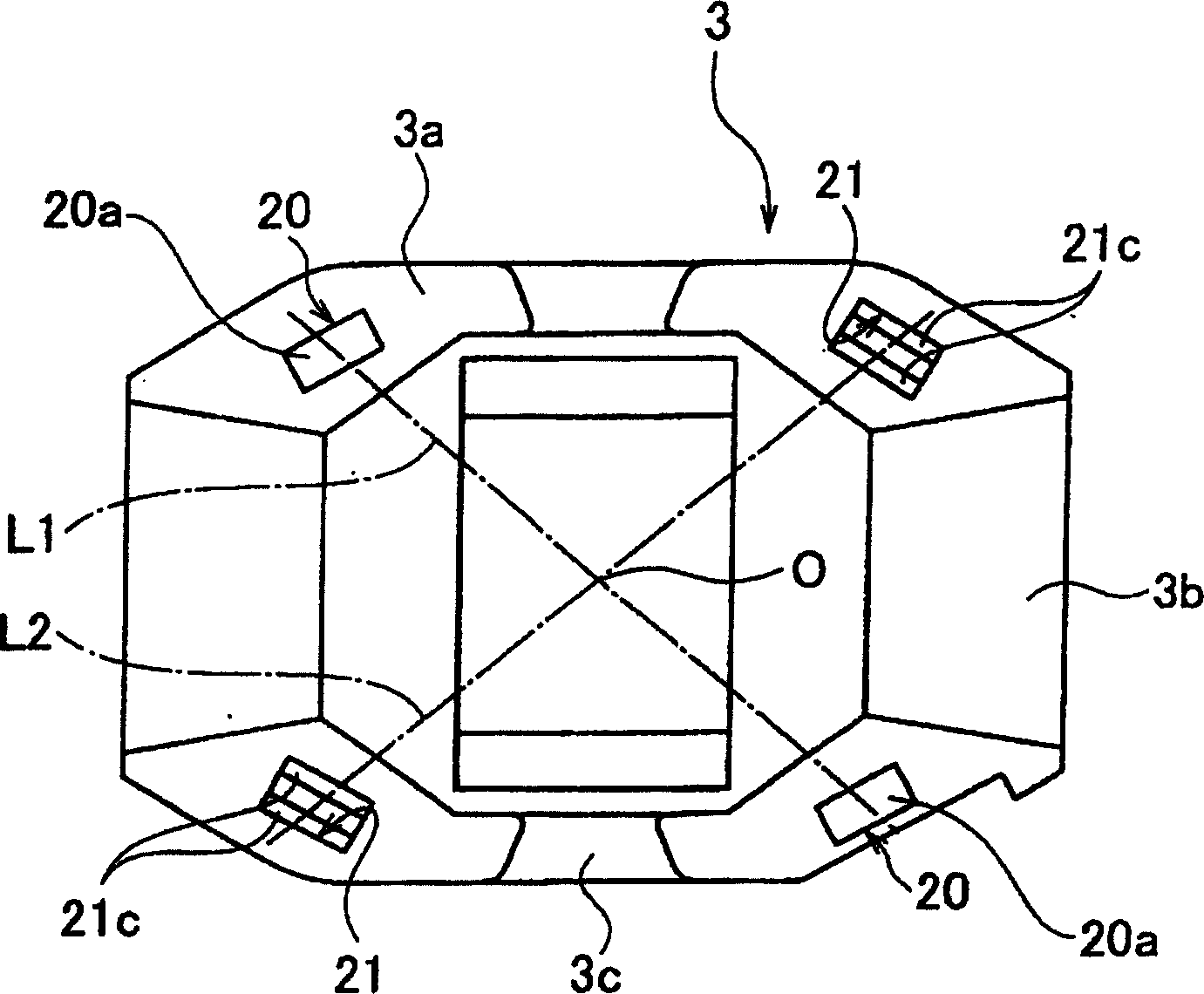

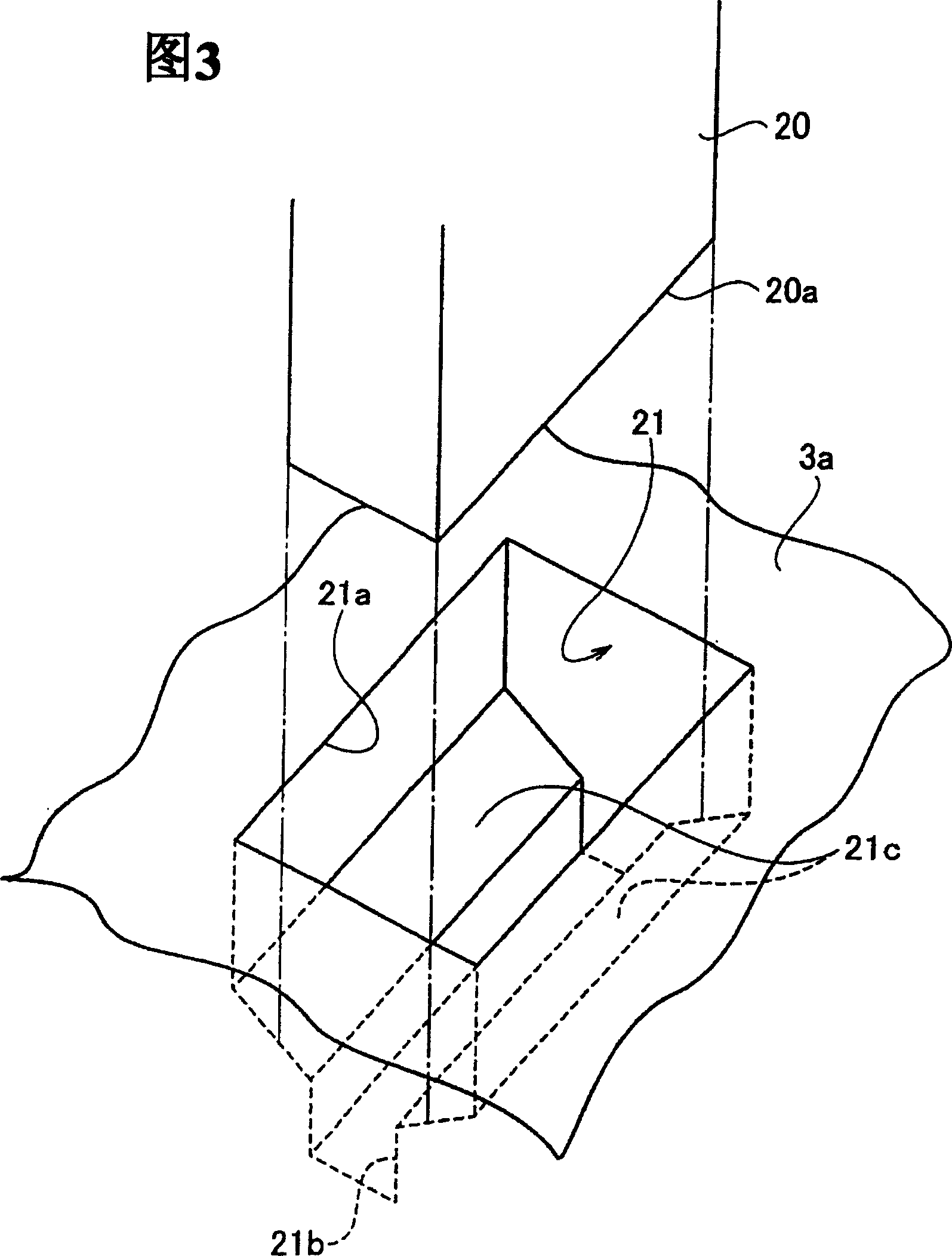

[0070] As shown in FIGS. 1-7, a pair of resin parts 3 and 3 are the same member, and joint faces 3a and 3a are provided with wire abutment faces 16 on which shielded wires 1 and ground wires 2 are respectively abutted....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com