Gas-liquid exchanging tower

A technology of gas-liquid exchange and tower body, which is applied in the field of environmental protection and chemical equipment, can solve the problems of tens of meters to tens of meters and high cost, and achieve the effect of low price, equipment cost reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

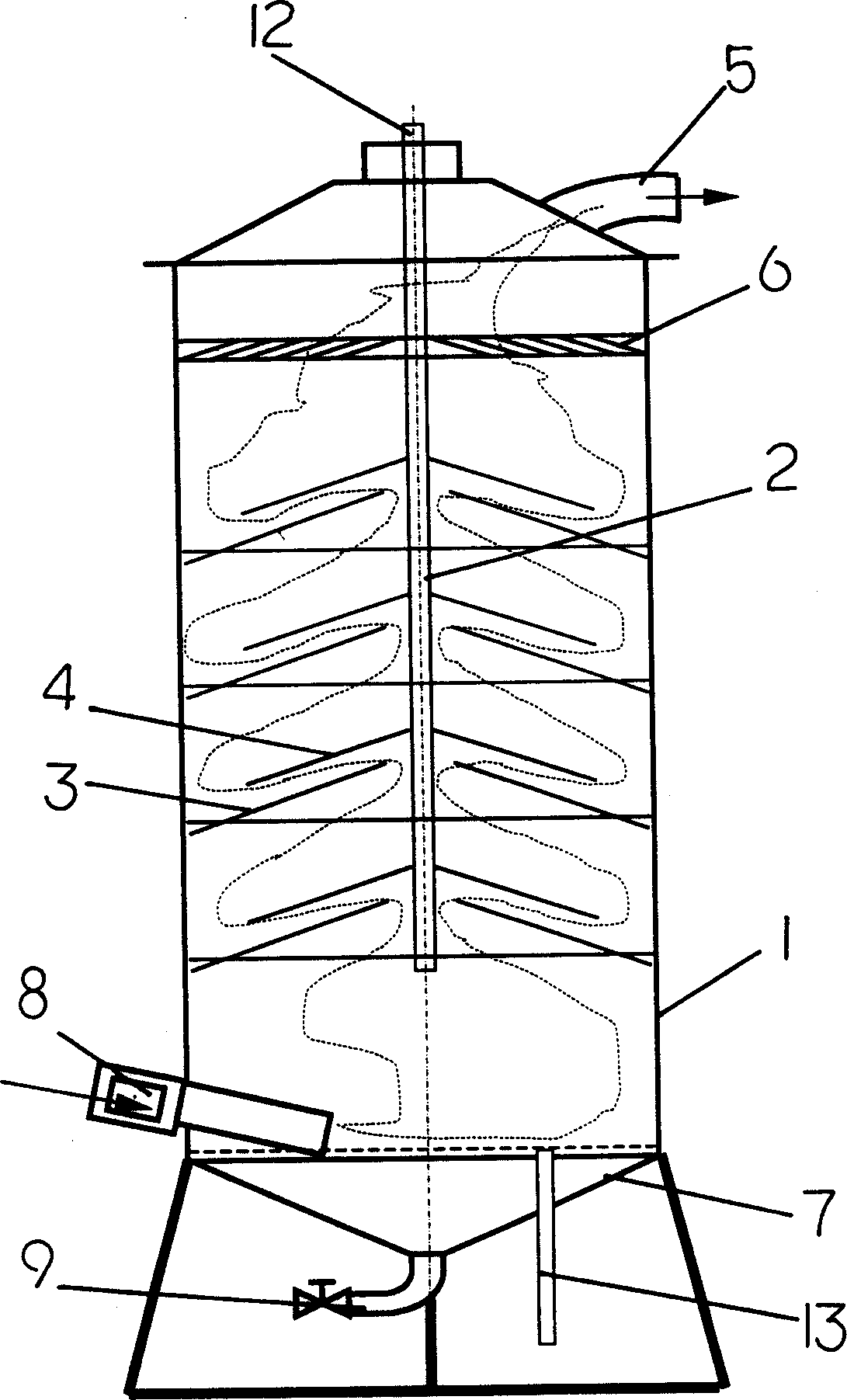

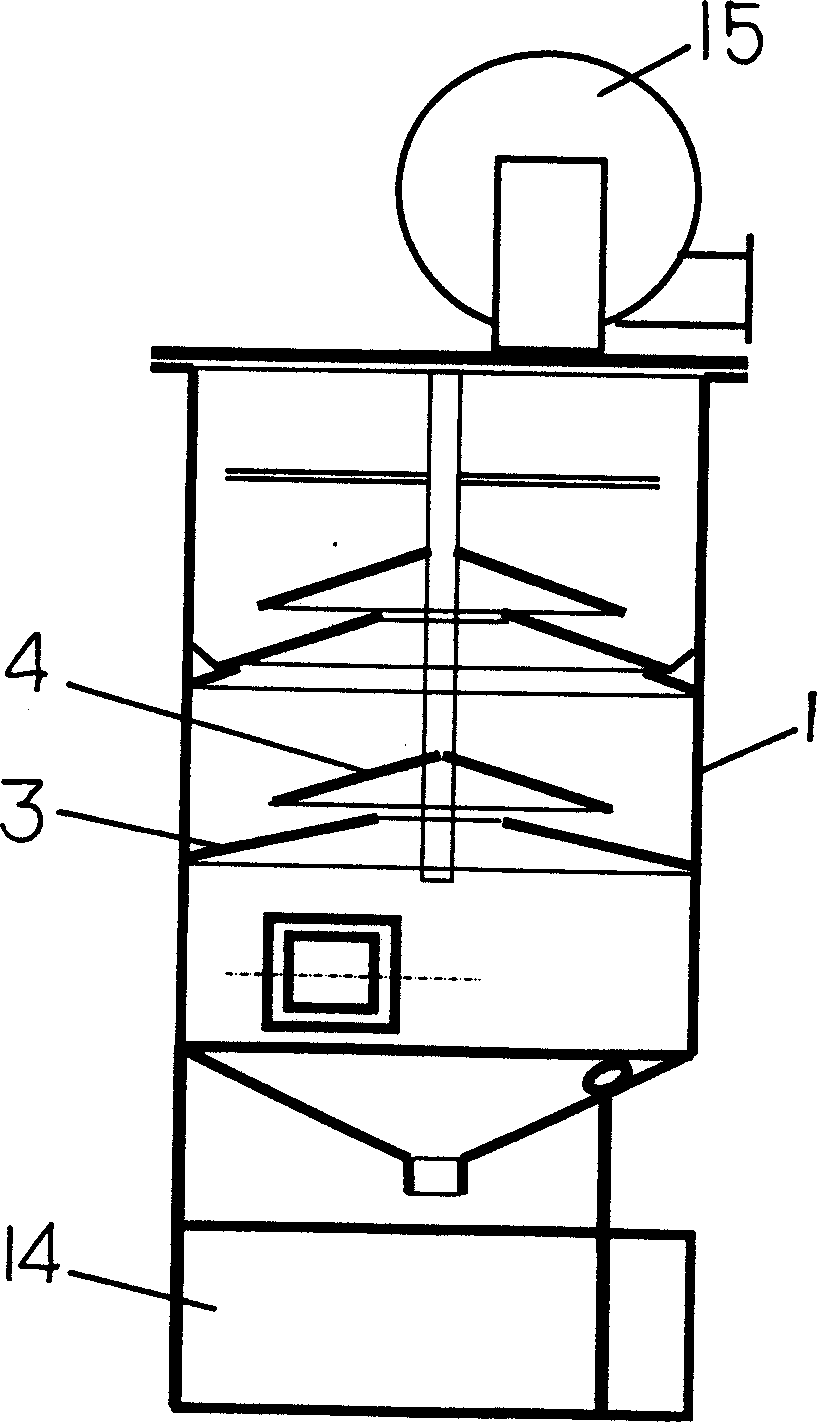

[0028] Referring to the accompanying drawings, a tower structure is adopted, and in its cylindrical tower body 1, a liquid spray pipe 2 is arranged at the position of its central axis, and a radial spray nozzle is arranged on the liquid spray pipe 2, and each spray nozzle can have multiple The spray hole, as the top nozzle of the liquid spray pipe of the circulating liquid inlet 12, stretches out from the top of the tower. The radial spraying and atomization of water formed by the spray hole can effectively improve the efficiency, and the direction of the spray hole can also be properly set so that the spray direction is consistent with the rotation direction of the airflow and inclined downward.

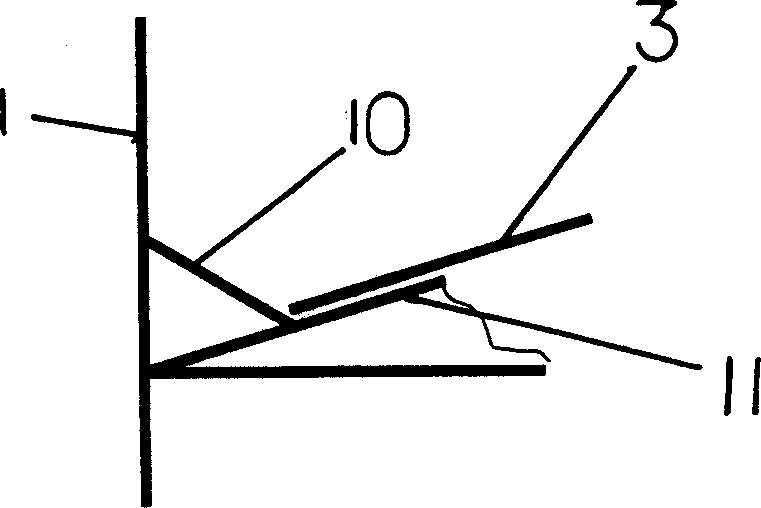

[0029] Such as figure 1 As shown, in the tower body 1, multi-layer baffle channels are set, and each layer of baffle channels is composed of a collector ring 3 that is an umbrella surface and a deflector plate 4 that is also located above the collector ring 3 and that is an umbrella...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com