Automotive floor panel structure

A panel and floor technology, applied in the field of the floor panel structure of the body, can solve the problems of increased cost, increased resonance frequency, increased vehicle weight, etc., and achieves the effects of reducing noise and reducing acoustic emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below with reference to the accompanying drawings.

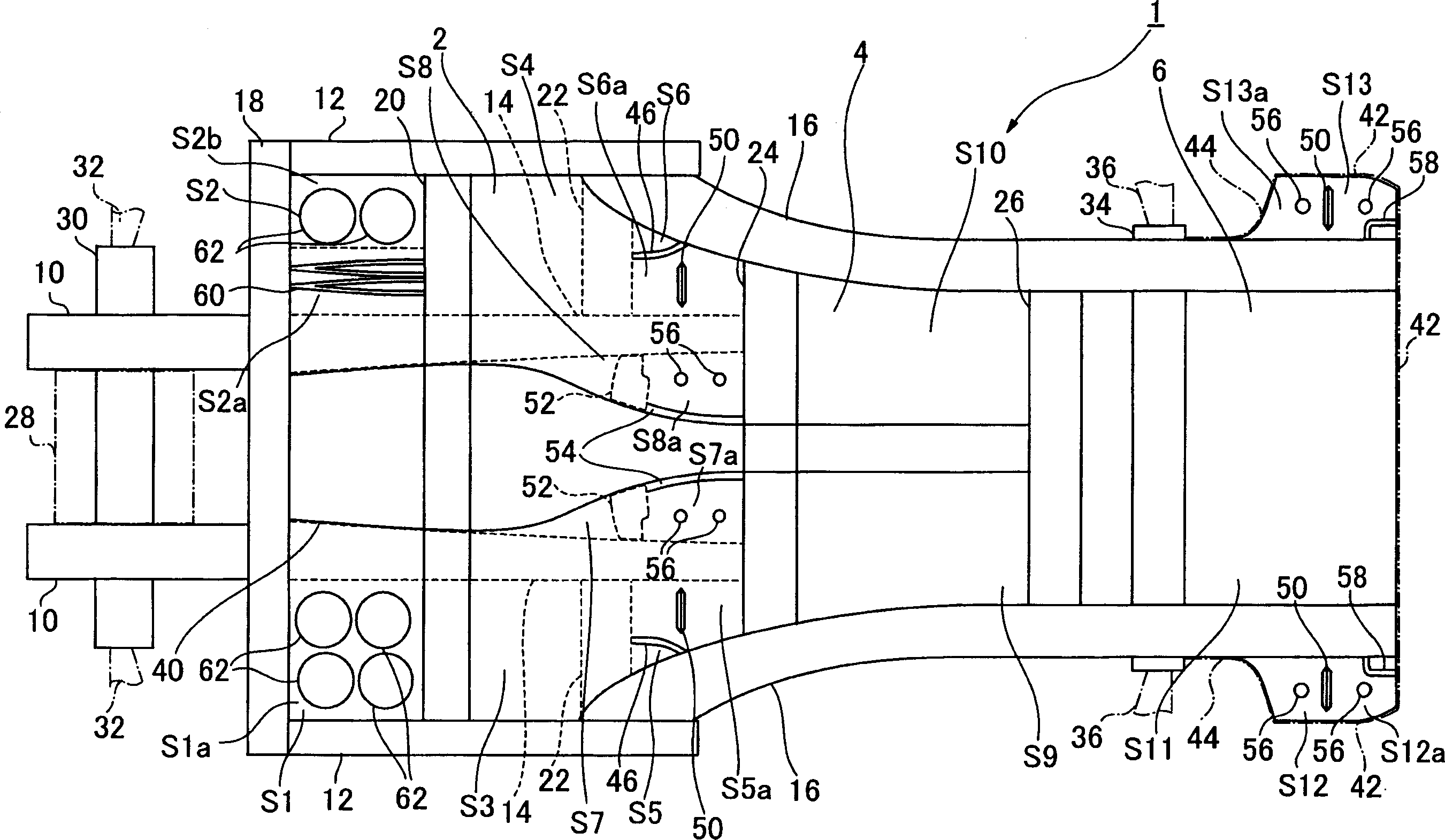

[0048] figure 1 It is a plan view of an automobile body base provided with a body floor panel structure in an embodiment of the present invention.

[0049] like figure 1 As shown, the lower body part 1 comprises a plurality of frame elements, and a front floor panel 2 constituting a compartment floor part connected to the above-mentioned frame elements is located higher than the front floor panel and behind the front floor panel 2 (in the direction of the vehicle body). ) at the position of the center floor panel 4, and a rear floor panel 6 constituting the trunk floor portion, which is located higher than and behind the center floor panel 4 (in the direction of the vehicle body) ) in the position.

[0050] The aforementioned frame elements are the front side frame 10 , the side sills 12 , the bottom side frame 14 , the rear side frame 16 , the No. 1 cross memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com