Optical engine lighting system

A lighting system and optical engine technology, applied in optics, optical components, nonlinear optics, etc., can solve problems such as low product qualification rate, color cast of projection screen, complicated process technology, etc., and achieve simple structure and technical difficulty and low cost , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

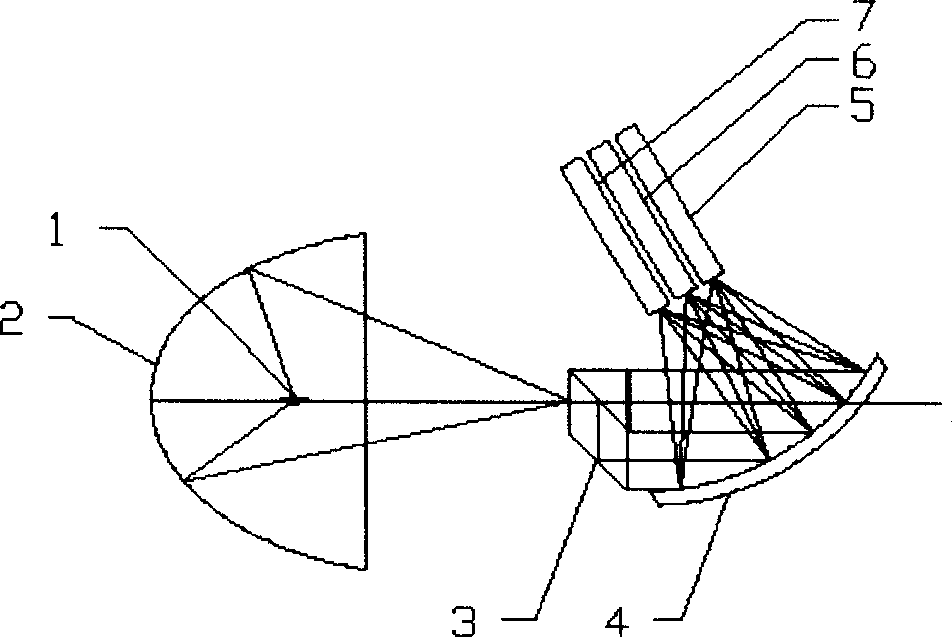

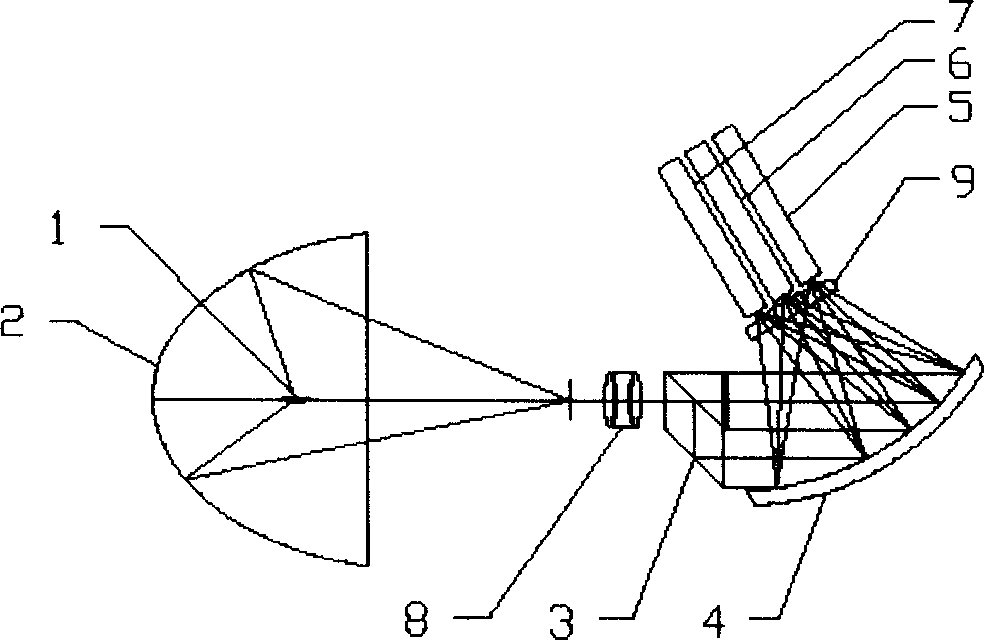

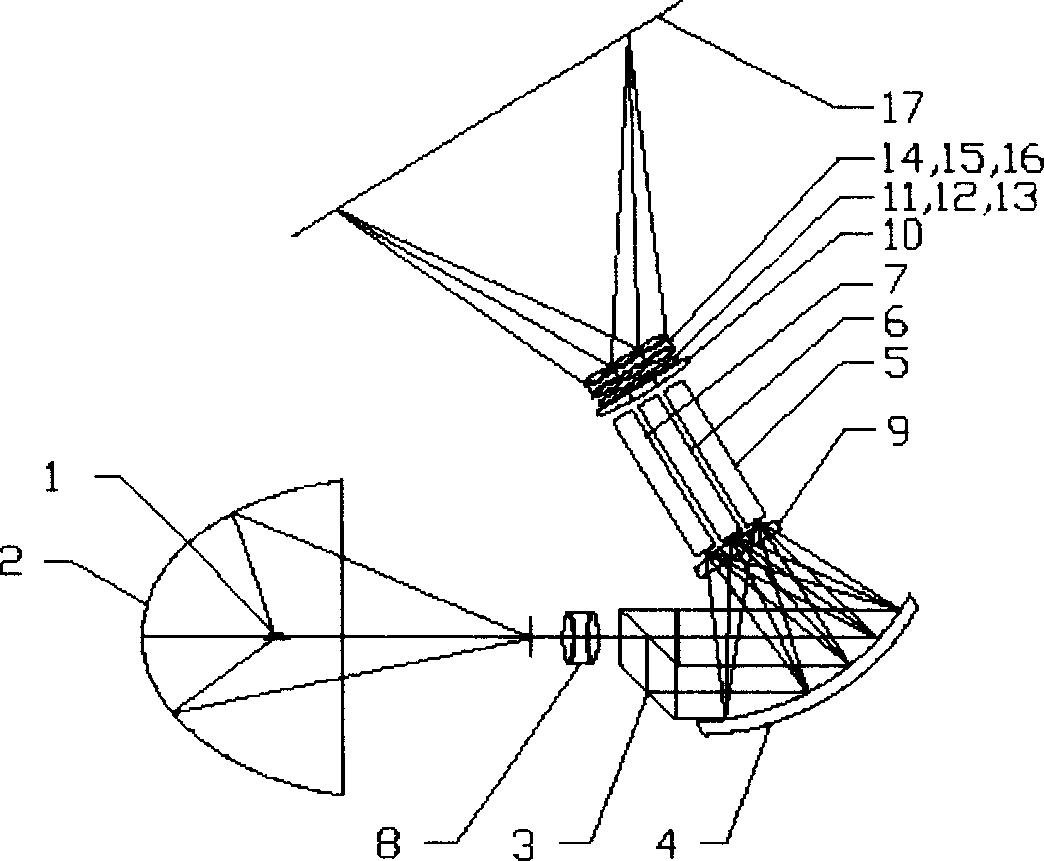

[0017] Such as figure 1 As shown, the present invention includes: a white light source 1, an ellipsoidal reflective bowl 2, a non-array polarizing prism group 3, a grating device 4, and optical rod devices 5, 6, and 7. The white light source 1 is placed at one focal point of the ellipsoidal reflective bowl 2, and its white light beam converges at the other focal point of the ellipsoidal reflective bowl to form the incident light spot of the system. The incident light spot is incident on the non-array polarizing prism group 3, and the beam-splitting surface of the non-array polarizing prism group 3 decomposes the incident light into the transmitted P component and the reflected S component, wherein the S component is reflected by the prism again and exits along the optical axis direction, while The P component is converted to the S component after being passed through a half-wave plate. If the half-wave plate is moved below the prism, the system will output P-polarized light. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com