Submersible motor for hot water well

A submersible motor, hot water well technology, applied in electrical components, electromechanical devices, electric components and other directions, can solve the problems of mechanical seal failure, easy scaling, low temperature resistance, etc., to achieve reliable mechanical seal, avoid high temperature vaporization, manufacturing simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

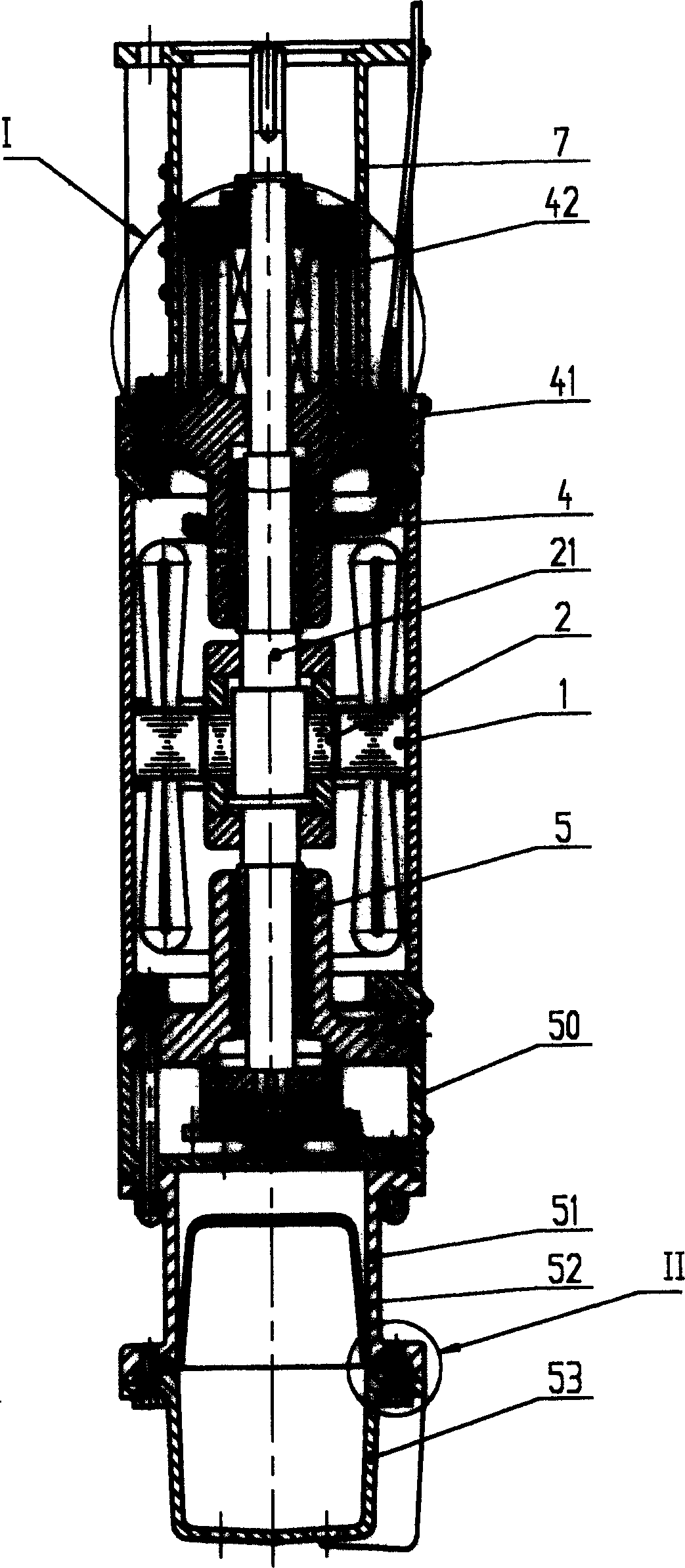

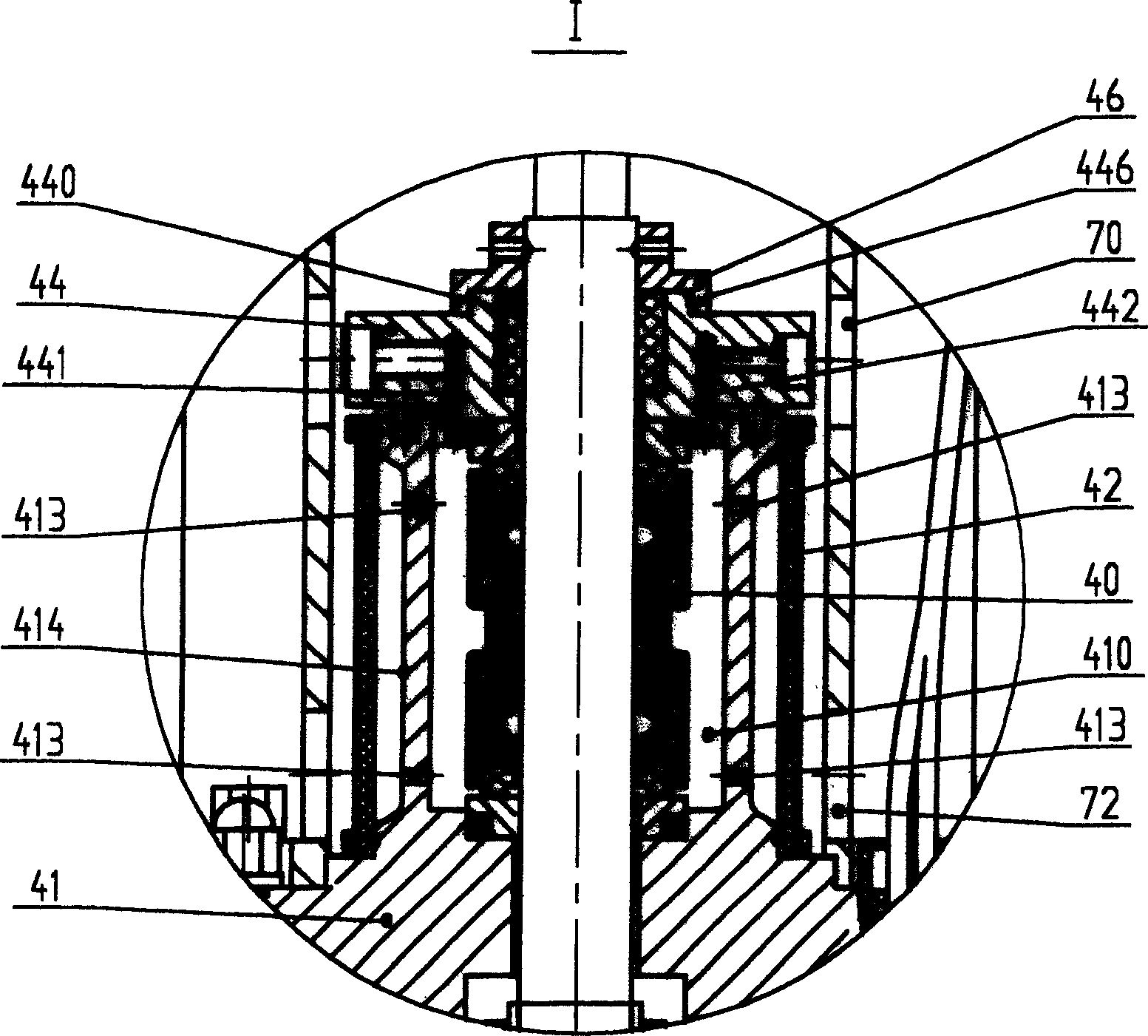

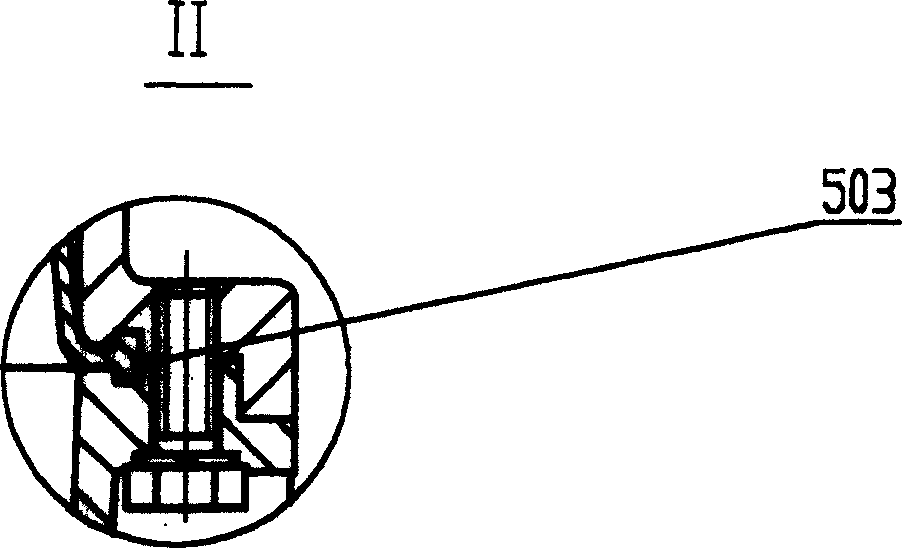

[0030] please see Figure 1-3 , a submersible motor for hot water wells, mainly composed of a flange 7, a double-end mechanical seal 40, an upper guide bearing assembly 4, a stator 1, a rotor 2, a lower guide bearing assembly 5, a thrust bearing seat 50, and a capsule bag 52 , capsule cavity 51, base 53 and other parts, it includes flange 7, upper guide bearing assembly 4, stator 1, lower guide bearing assembly 5, thrust bearing seat 50 and base 53 connected sequentially from top to bottom, and The rotor 2 is installed in the stator 1, and its rotating shaft 21 is positioned radially and axially by the upper guid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com