Apparatus and process for edgefold and seal of liquid packing bag

A process method and packaging bag technology, applied in the field of liquid packaging bag folding and sealing devices, can solve problems such as difficult operation, large packaging cost, and complex equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

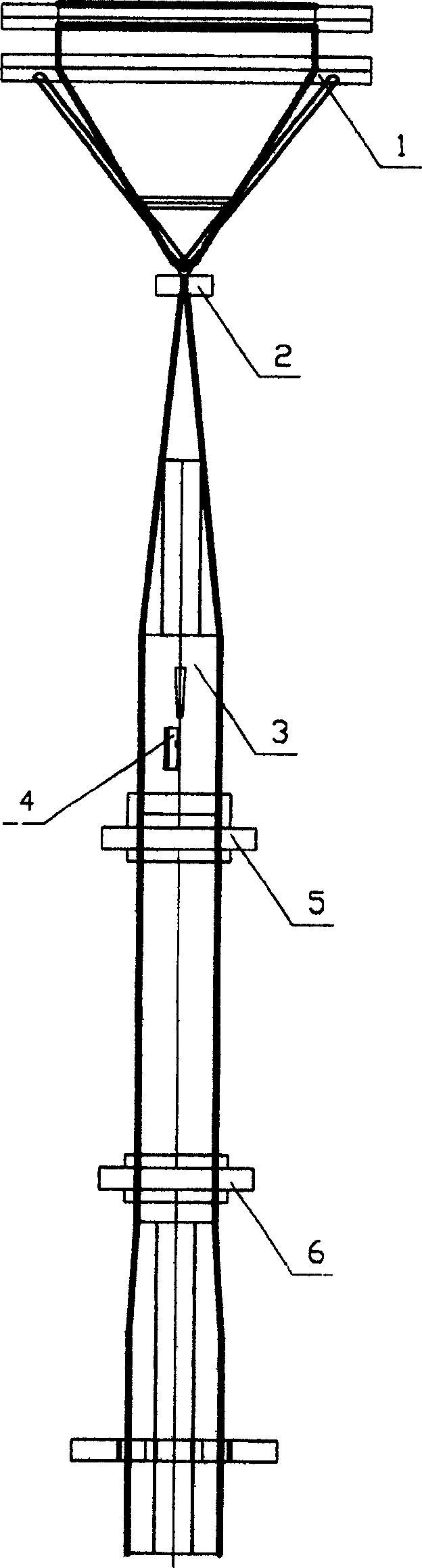

[0013] Such as figure 1 As shown in the figure: the paper-plastic packaging bag back-sealing forming device has a flipped tripod (1), and the lower part of the tripod is a clamping device (2); the lower part is a filling and forming tube (3), which is filled and formed There is a flanging device (4) on the tube; the lower part of the filling and forming tube is the forming ring (5) and the forming ring (6); the packaging material is pulled to the film turning tripod (1) by the guide roller, and is turned The tripod is folded into a triangle and pulled down vertically. When entering the gripper (2), the packaging material is folded into an inverted "U" shape and then pulled down. When the packaging material moves downward, the side of the packaging material on one side is turned over by the filling molding tube (3). The edge device (4) is folded into a flange with a width of about 5mm, and the flange of the packaging material overlaps with the edge on the other side of the pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com