Optical fiber strain three-dimensional simulation experimental bench

A technology for simulating experiments and optical fiber strain, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of difficult determination of optical fiber strain and actual stress and deformation, and inability to analyze and predict building stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

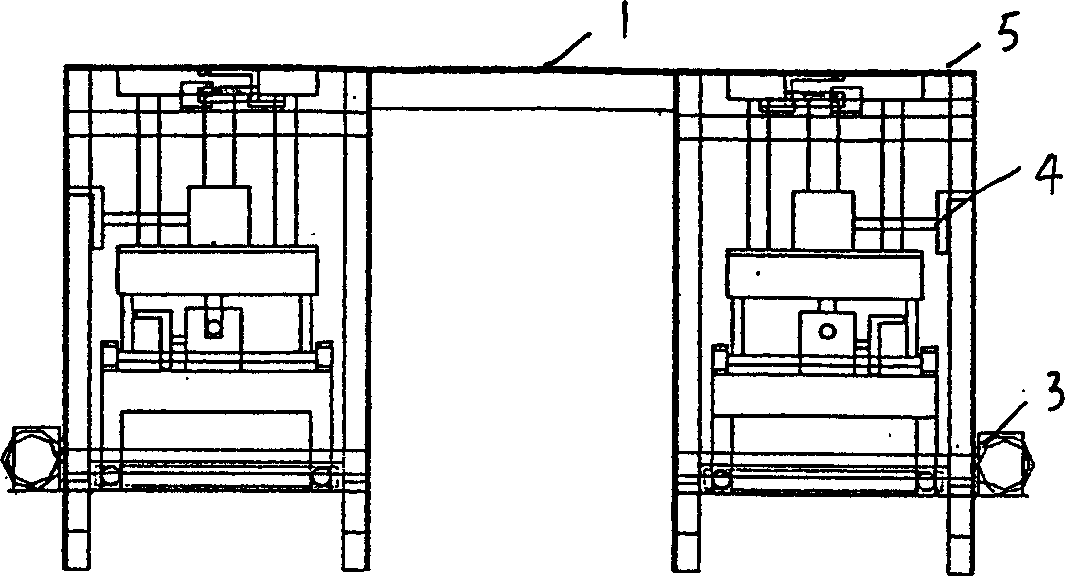

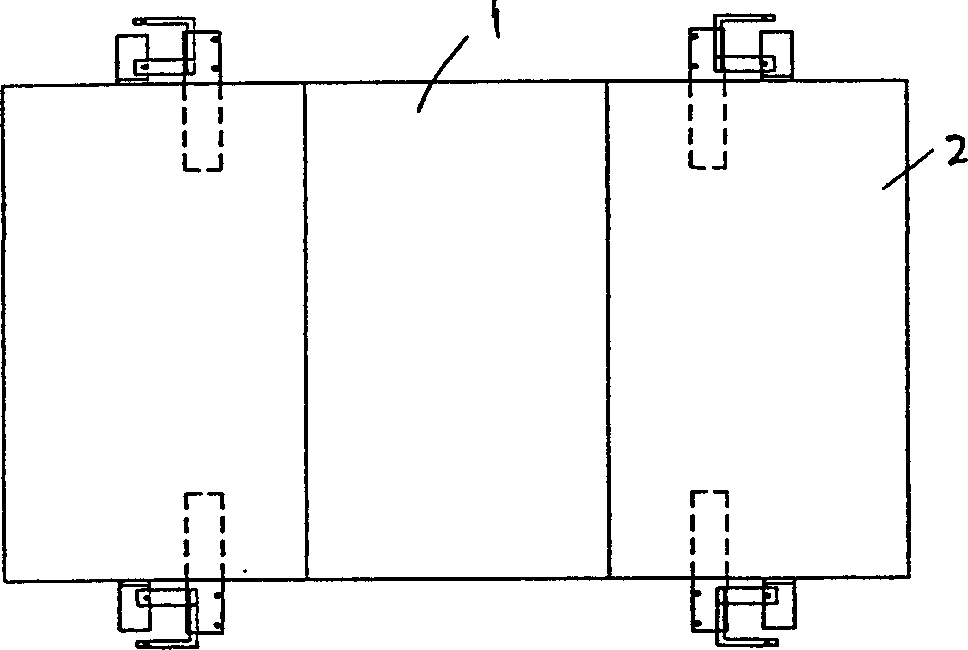

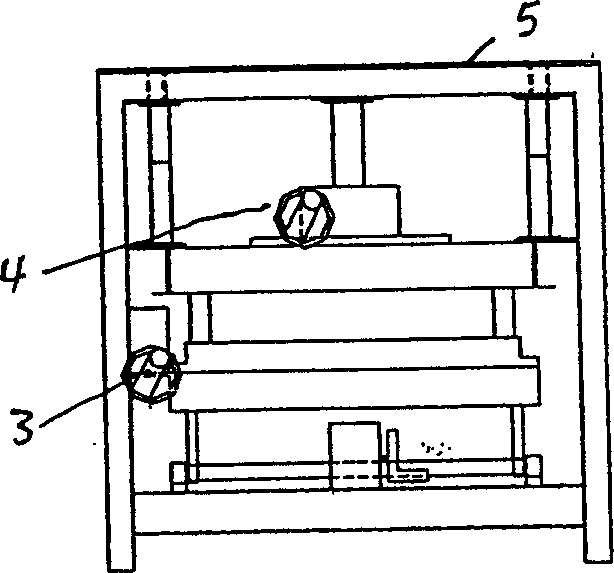

[0013] The test bench mainly consists of three independent platforms. The platform in the middle is the reference platform, and its height and angle remain unchanged. Two movable platforms are separated on both sides. The lower part of the platform is equipped with a horizontal driving part 3 and an upper and lower driving part 4. It is a three-dimensionally arranged screw handle. The spiral and the platform of the movable platform are fixed in layers, and the two movable platforms can be controlled to perform horizontal and vertical three-dimensional movements by shaking the crank under the platform. Between the platforms, a dial indicator or a dial indicator displacement measuring instrument is installed to measure the horizontal and vertical displacement, so as to organically combine the displacement with the detection results such as BOTDR.

[0014] More specifically, the driving device screw rocker of the three-dimensional motion is a worm gear 3 device, and the flat plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com