Water level measuring apparatus

A water level measurement and instrument technology, applied in the field of water level detection and control devices, can solve the problems of large consumption of electrolytic corrosion, electrode corrosion, backward compensation methods, etc., and achieve the effect of extensive operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

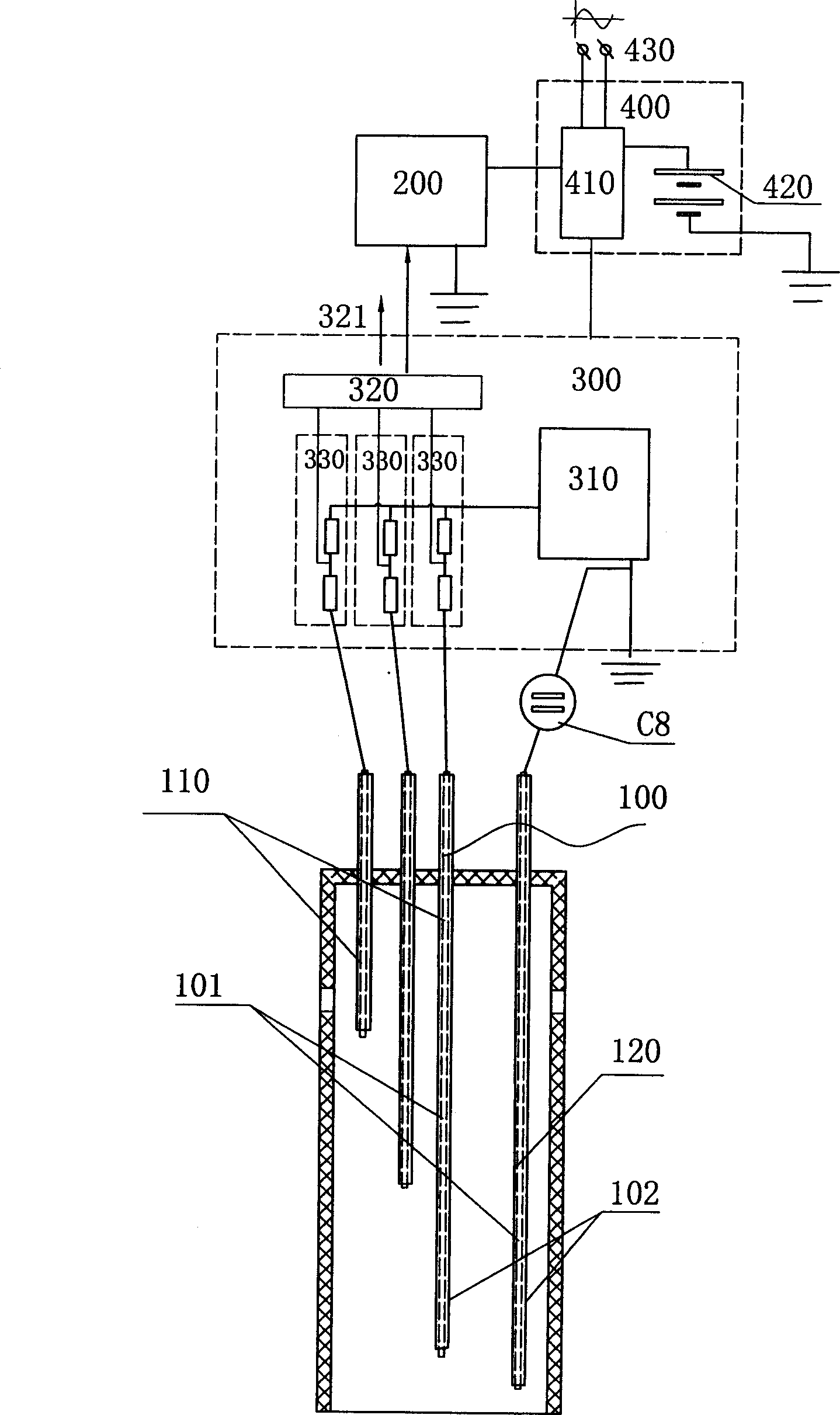

[0025] Such as figure 1 Shown: a water level measuring instrument, the instrument includes the following components: a detection electrode 100, a display circuit 200, a detection control circuit 300, and a power supply circuit 400, wherein the power supply circuit 400 provides power to other circuits, and the detection electrodes 100 are many There are two, including the liquid level electrode 110 and a return electrode 120 located at the bottom of the liquid level, and the detection control circuit 300 includes a pulse generation circuit 310, a processing circuit 320 composed of semiconductor switching tubes and each liquid level electrode 110 A coupled coupling circuit 330, wherein the coupling circuit 330 has three heads, which are respectively connected to the output end of the pulse generating circuit 310, the input end of the processing circuit 320, and one of the liquid level electrodes 110; and the return electrode 120 is connected to the The ground wire of the power s...

Embodiment 2

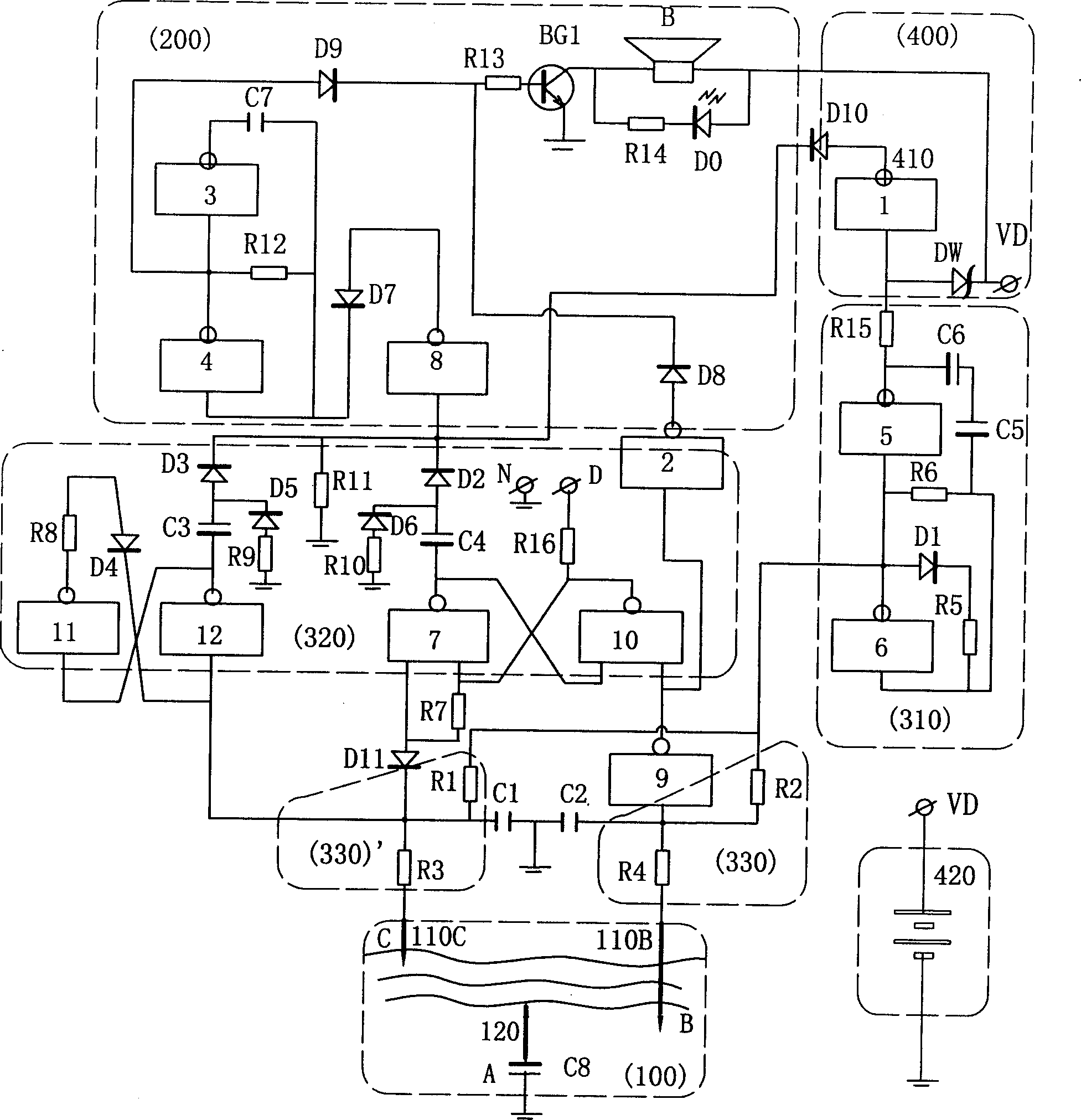

[0030] Such as figure 2 Shown: a kind of water level measuring instrument of the present invention, this instrument comprises following parts:

[0031] The detection electrodes 100 are divided into two types according to their functions: two liquid level electrodes 110 : 110B and 110C are respectively set at different liquid level heights; one return electrode 120 is set at the bottom of the liquid level. The two liquid level electrodes 110B and 110C are respectively connected to the gate circuits 7 and 9 through R3 and R4, and the lower ends are respectively inserted into the liquid at different depths. One end of the return electrode 120 is connected to the ground wire of the power supply through a large-capacity capacitor C8, and the other end goes deep into the liquid. To the bottom of the measured liquid, forming a current loop with a liquid level electrode 110;

[0032] The display circuit 200 includes a display signal generation circuit composed of gate circuits 3 and...

Embodiment 3

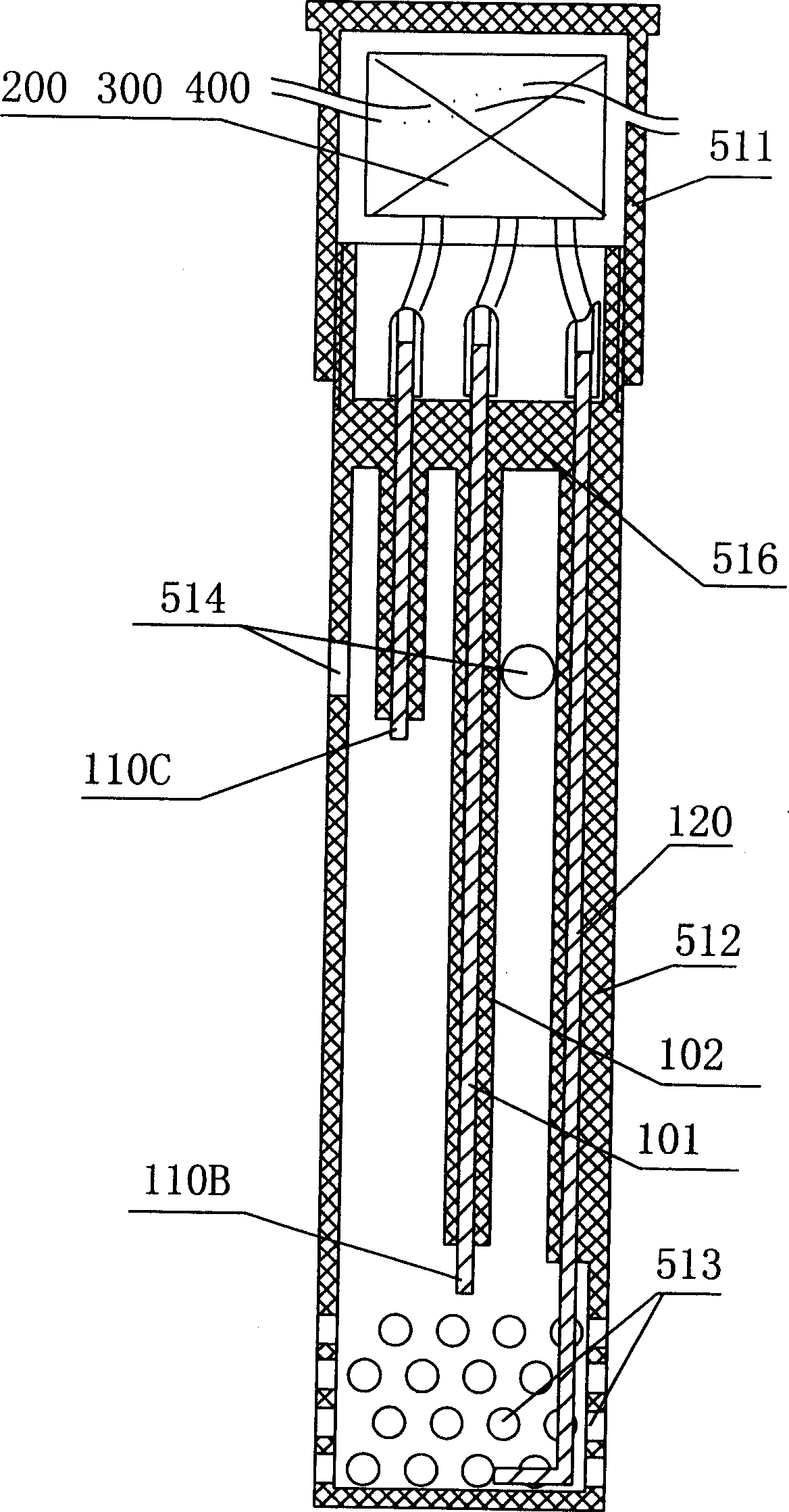

[0038] Such as image 3 Shown: a pen-type water level measuring instrument used in hydroponic potted plants according to the present invention. The external dimensions of the water level measuring instrument are: length 115 mm, diameter 15 mm, which can be easily inserted into the cultivation pot. The pen-type water level measuring instrument is composed of upper and lower long cylinders 511, 512 connected detachably; the upper cylinder 511 is equipped with a detection control circuit 300, a power supply circuit 400, and a display circuit 200; The bottom of the lower cylinder 512 is provided with several permeable holes 513, the upper part of the lower cylinder 512 is provided with a ventilating liquid level upper limit hole 514, the top 516 of the lower cylinder 512 is a sealing end surface, and the detection electrode 100 is fixed on the top 516 of the lower cylinder 512. The upper end of the detection electrode 100 protrudes from the upper surface of the top end 516 to conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com