Multi-color fiber pile cloth and multi-color fiber pile cloth with concave-convex pattern

一种毛绒织物、纤维的技术,应用在织物、刺图案、纤维处理等方向,能够解决没有令人满意实现等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

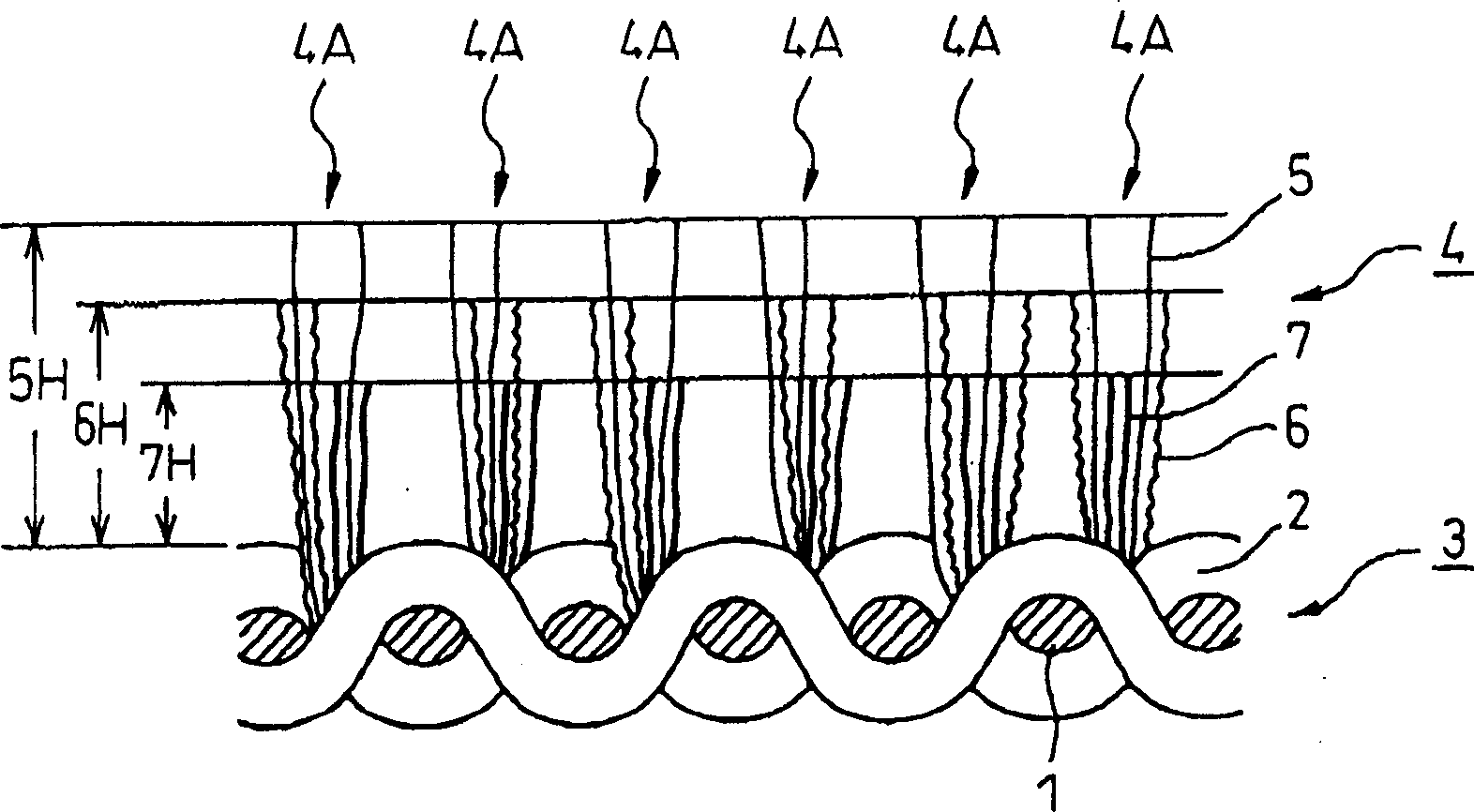

[0112] Polyethylene terephthalate multifilament yarn (yarn count: 84dtex / 36 filaments) is heat-treated under the treatment conditions, that is, the heater length is 2m, the heat treatment temperature is 200°C, and the heat treatment speed is 500m / min. The percent overfeed was 5%.

[0113] The obtained non-shrunken polyester filament yarn (1) had a shrinkage in boiling water of 1.2%.

[0114] Separately, polyester dyeable with cationic dyes can be produced as follows: In the production of polyethylene terephthalate by polycondensation, the acid component contains 2.6 mol% of the total molar amount of the acid component. Phthalic acid to copolymerize cationic compounds into polyethylene terephthalate. From the obtained polyester dyeable with cationic dyes, a shrunken polyester filament yarn (2) with a count of 100 dtex / 24 filaments was produced with a false twist process of 21% Shrinkage percentage.

[0115] Further separately, made from an acid component containing terepht...

example 2

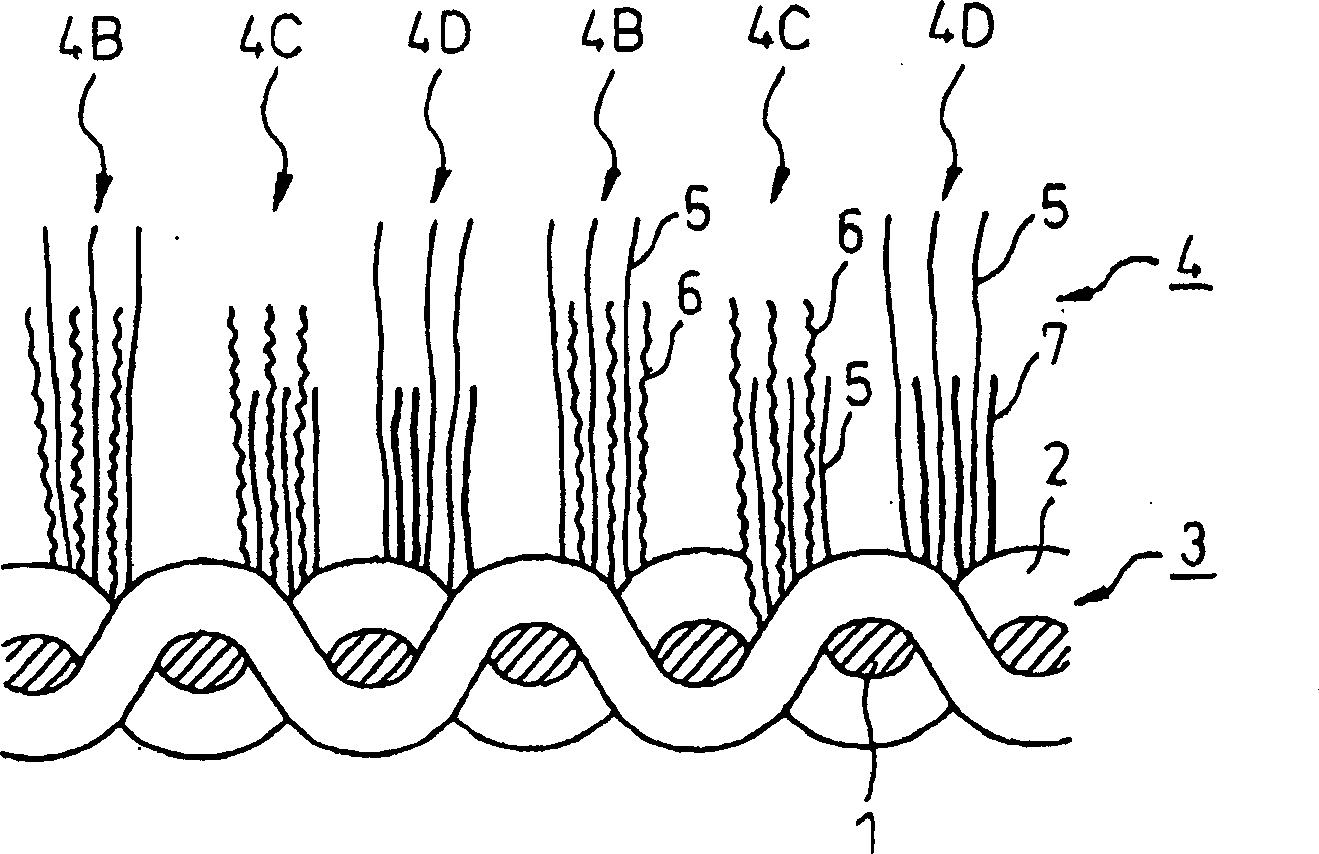

[0133] Make a kind of multi-color fiber plush fabric of concavo-convex pattern by the same process as example 1, difference is as follows.

[0134] As the filament yarn for forming the non-shrunk fluff fiber (1), non-shrunk polyester (polyethylene terephthalate) filament (1) composed of a resin is used, the The resin was dyed with a black dye, and the yarn count of the filament (1) was 75 dtex / 36 yarns. The boiling water shrinkage of the filament (1) was 1.2%.

[0135] Also, in the dyeing process, the dyeing process does not contain Teratop Pink 2GLA and Teratop Blue HLB. Thus in the cut pile layer, the crimped cationic dyeable polyester filaments (2) are dyed brown, and the dyed color is comparable in tone and brightness to the non-shrunk polyester filaments (1 ) are different in black. Furthermore, the non-shrunk copolyester filaments (3) are not dyed by the dyeing process.

[0136] In chemically etched cut pile fabrics, the concavo-convex pattern is formed by deep conca...

example 3

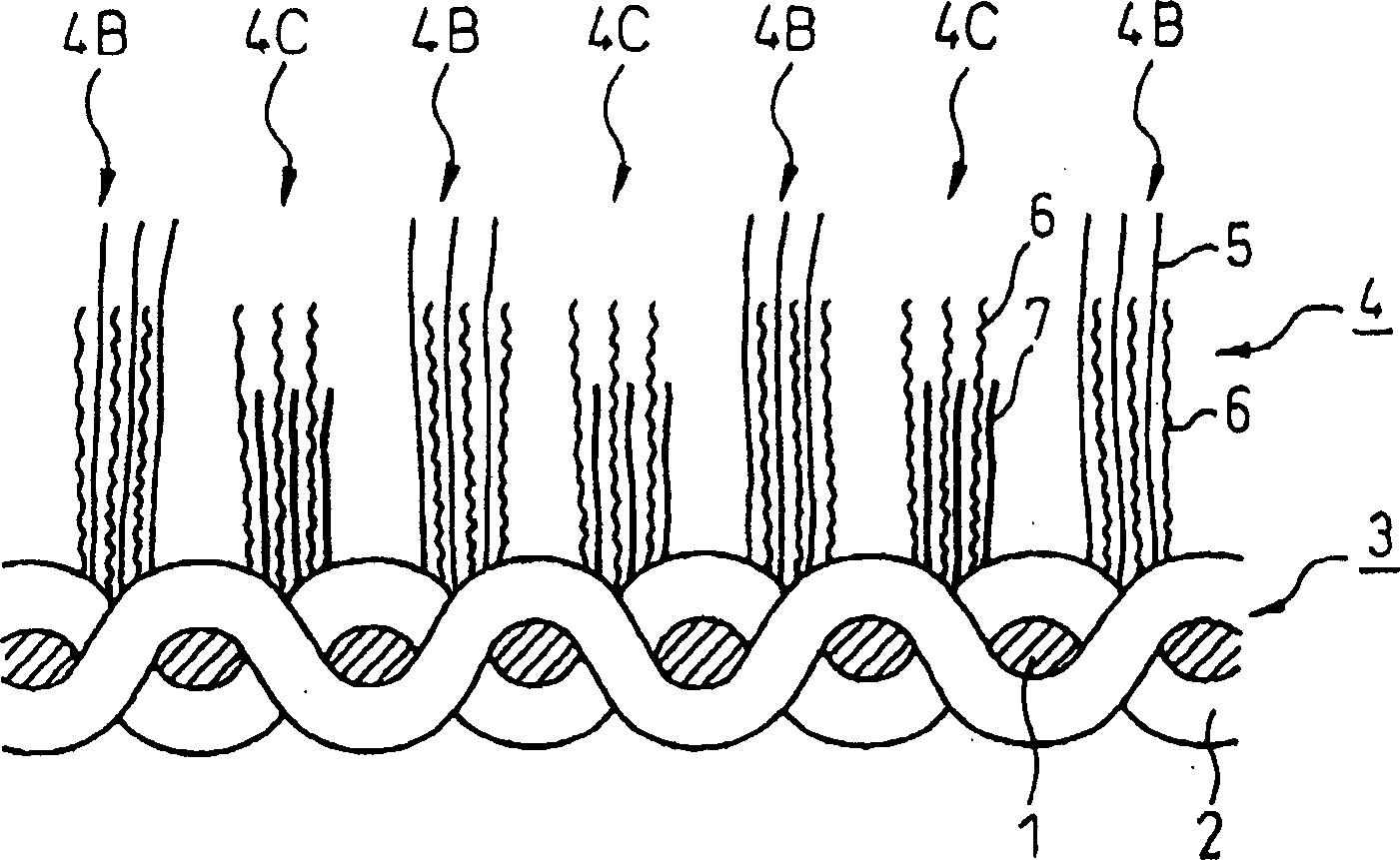

[0139] Make a kind of multi-color fiber plush fabric of concavo-convex pattern by the same process as example 1, difference is as follows.

[0140] Three kinds of fluff-forming filament yarns (1), (2) and (3) each having a total fineness of 284 dtex are respectively passed through polyester (PET) filaments (1) for non-shrunken fluff fibers (1) , consisting of cationic dyeable polyester filaments (2) for crimped fluff fibers (2) and non-shrinked copolyester filaments (3) for non-shrinked fluff fibers (3).

[0141] The filament yarns (1), (2) and (3) used to form the pile layer are the same as the polyester filament yarns used to form the ground structure in Example (1) and Figure 8 The illustrated knitting structure undergoes a knitting process in order to make a pile fabric. In the pile fabric obtained, a combination is repeatedly arranged in the wale direction: a lavender pile ridge comprising non-shrunken polyester pile fibers (1) having the highest pile height and having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com