Self-propelled anchor machine

A bolter, walking type technology, applied in the installation of bolts, mining equipment, earth drilling and mining, etc., can solve the problems that the jacking bolt and the anchor cable cannot work in parallel, the labor intensity of the workers is high, and the supporting speed is slow. To achieve the effect of preventing accidents caused by sheet gangs, saving material transportation time, and facilitating inspection and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

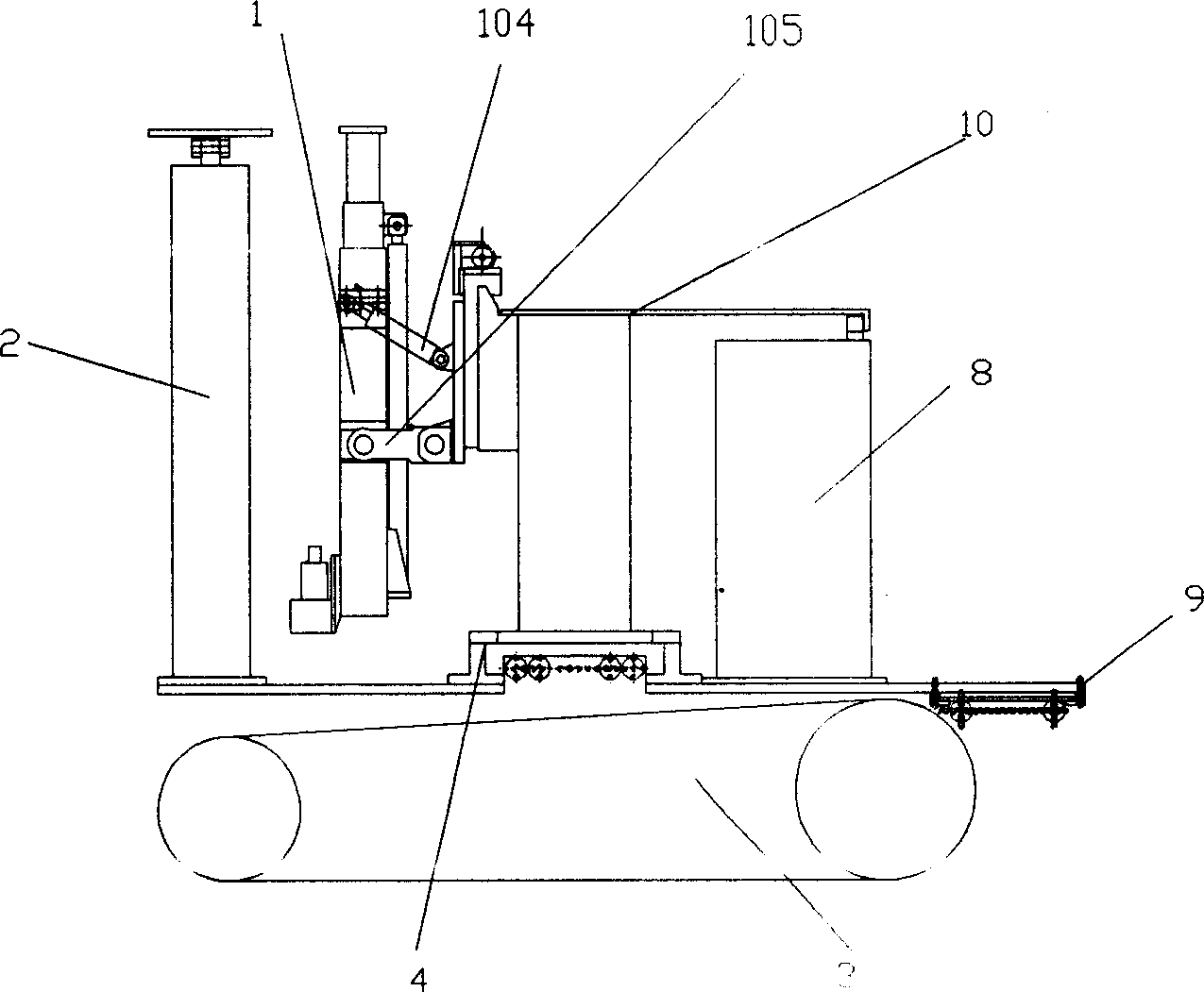

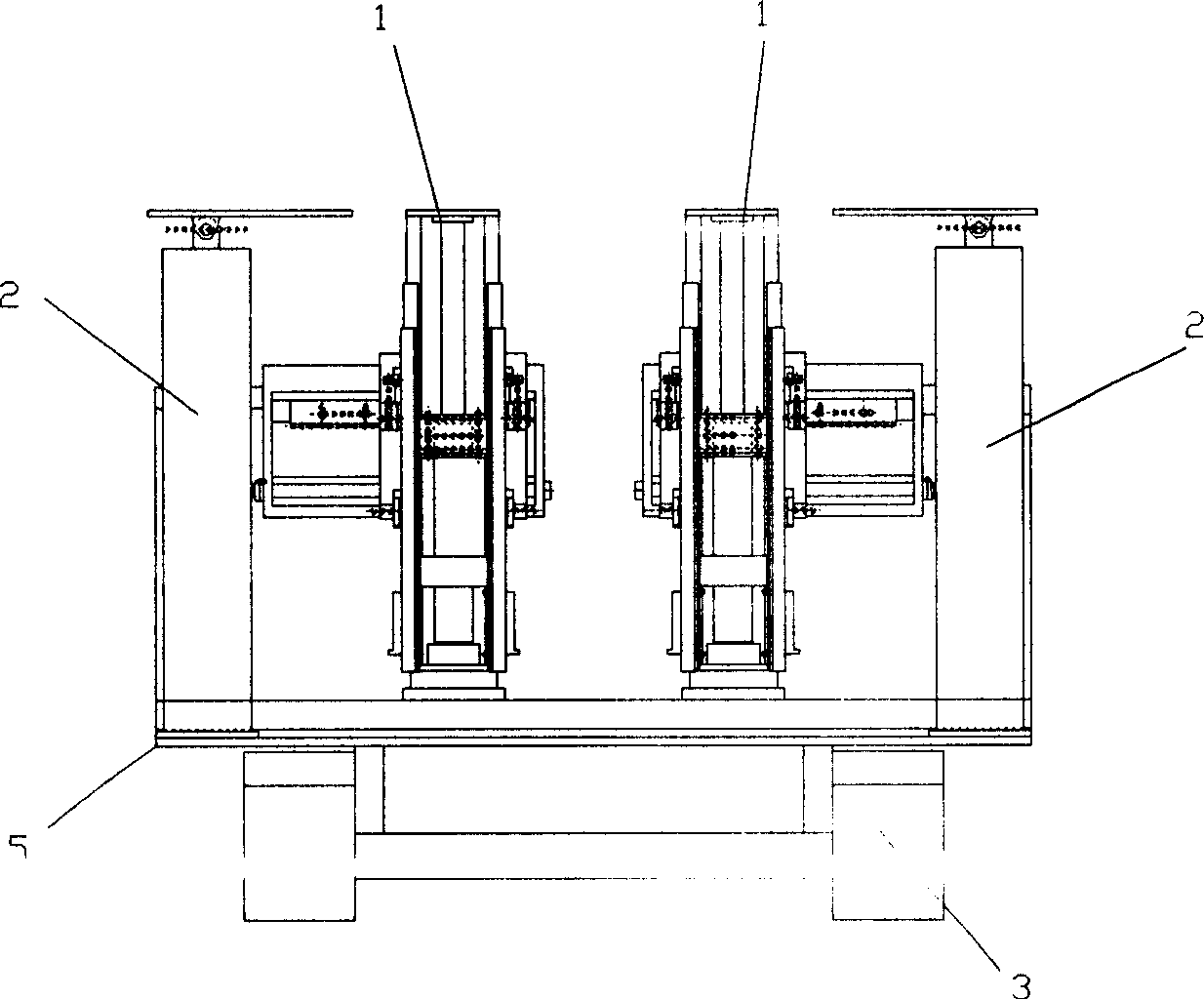

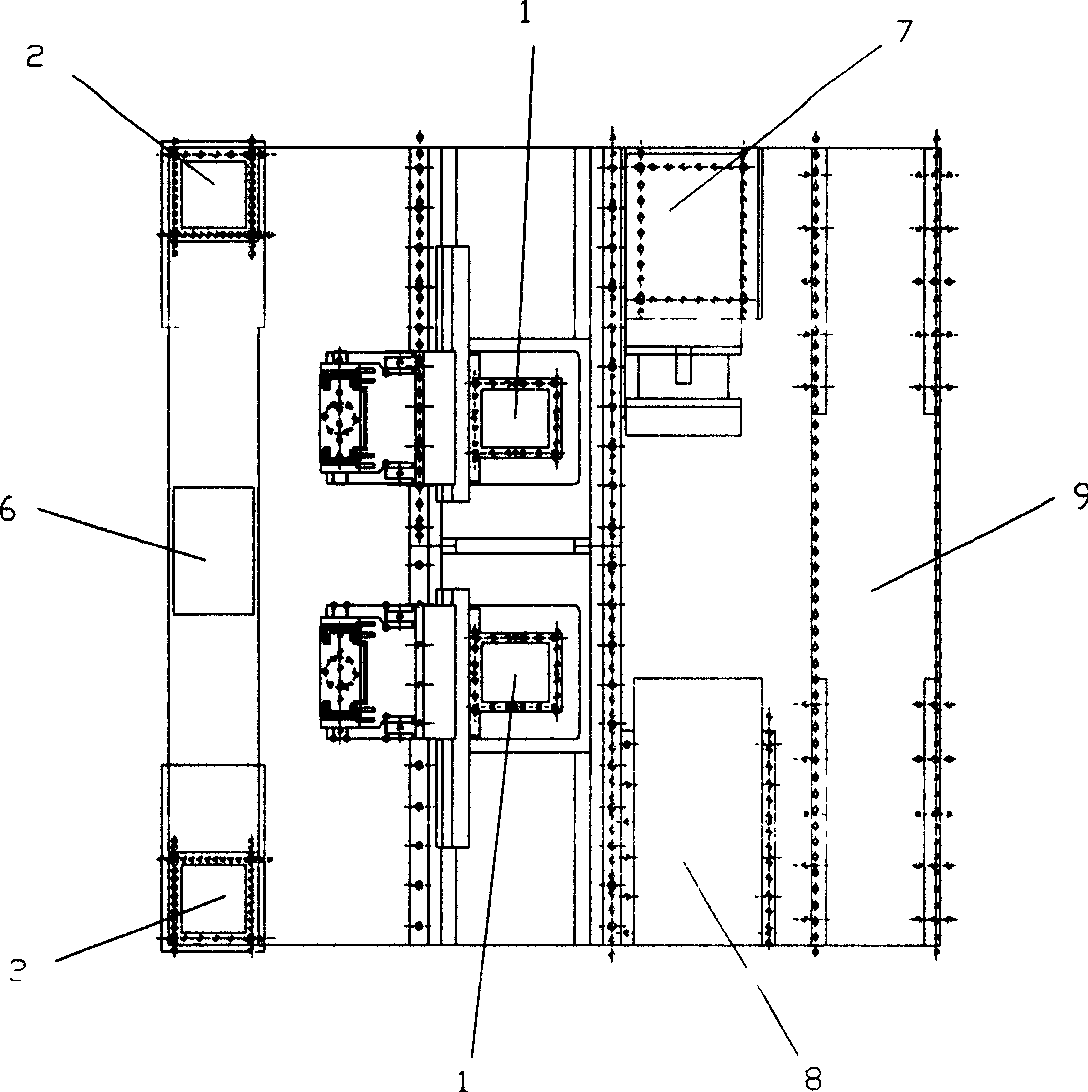

[0025] figure 1 , figure 2 and image 3 As shown, self-moving walking bolter. It has two drilling rig devices 1, two advanced supports 2, crawler-type traveling mechanism 3, the overall horizontal movement slideway 4 and platform 5 of the drilling rig device; the traveling mechanism is driven by a hydraulic motor, and the anchor rod is installed on the frame of the traveling mechanism Two hydraulic cylinder-type advanced supports are installed on both sides of the front end of the platform, and two drilling rig devices are installed behind the advanced support; the platform is equipped with an overall horizontal moving slideway for the drilling rig device, and the drilling rig device is installed on the moving slideway Electric control box 6, hydraulic pump station 7 and material box 8 etc. are also adorned on the platform. Each advance support of the bolter is composed of a square tubular support frame installed on the platform, a support oil cylinder installed in the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com