Portable double-sealing rotating cutting valve

A double-sealed, portable technology, used in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of large impact on seal life, large consumables, small axial size, etc., to extend service life and application safety. Reliable and improve the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

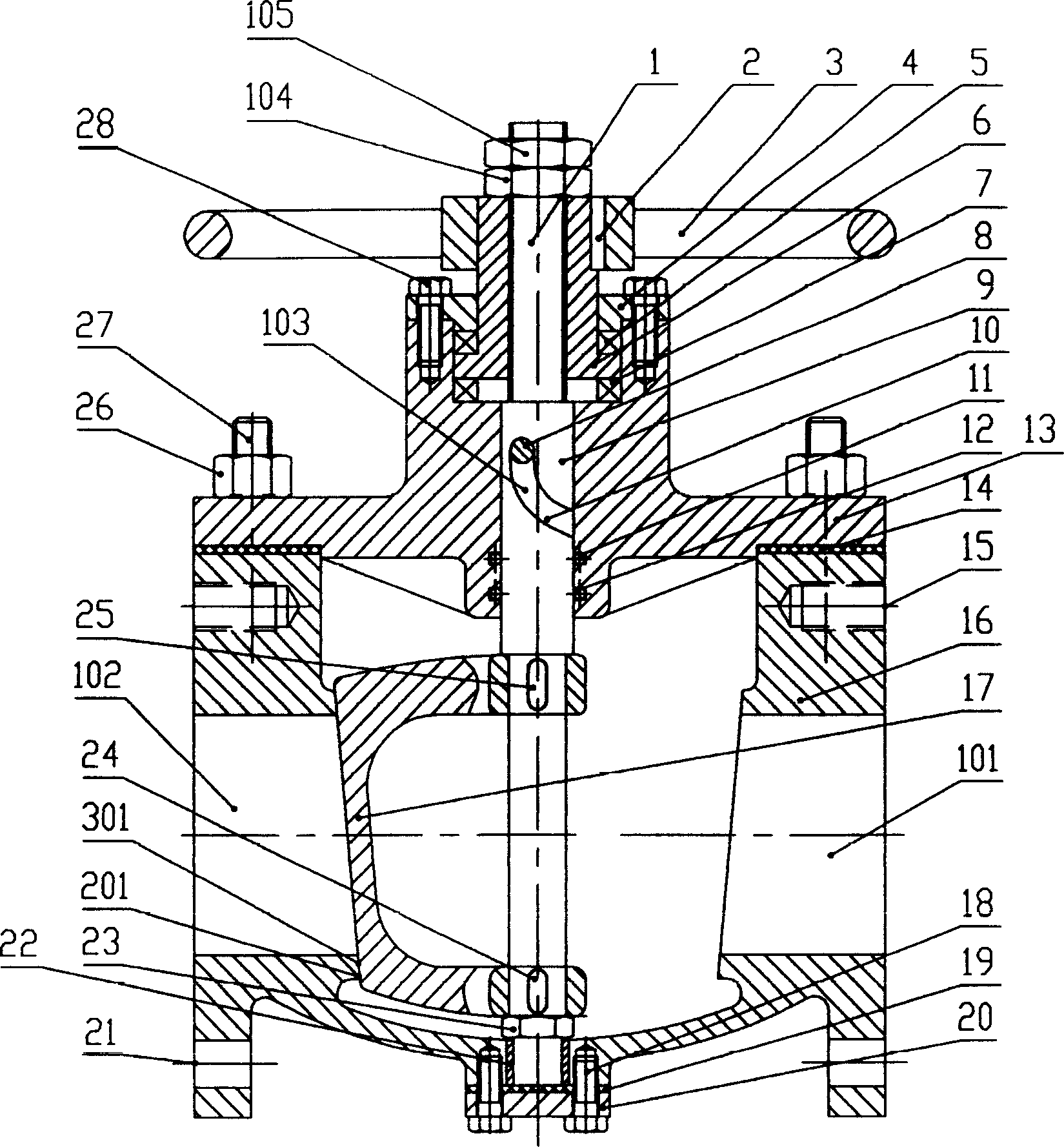

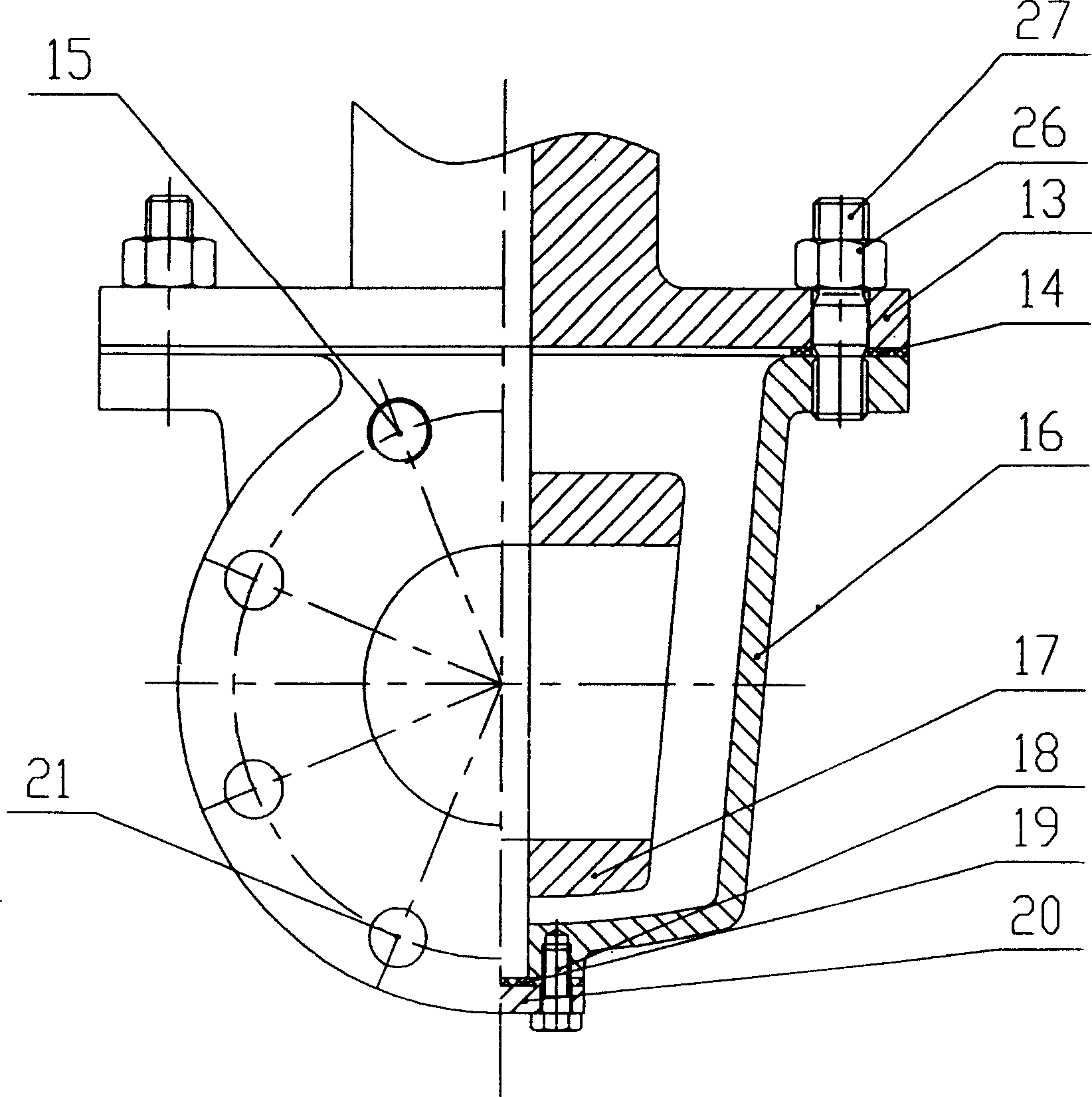

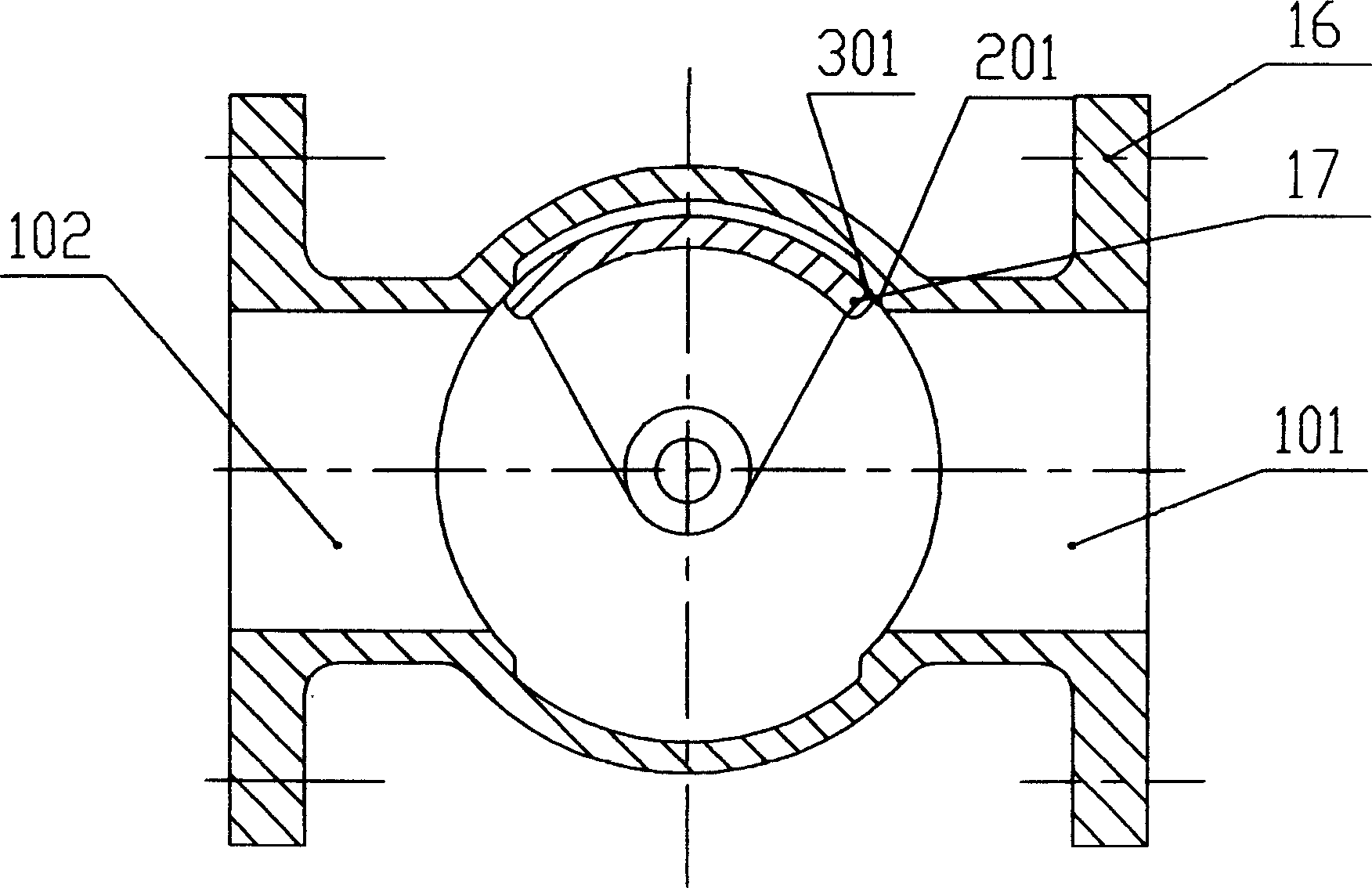

[0010] The present invention is made up of valve stem screw rod 1, key 2,24,25, transmission mechanism 3, bearing gland 4, transmission nut 6, upper bearing 5, lower bearing 7, pin 8, valve stem 9, valve stem straight groove 103, Stem inclined groove 10, valve cover 13, sealing rings 11, 12, sealing plate 14, flange screw holes 15, valve body 16, opening and closing parts 17, screws 18, sealing plate 19, bottom cover 20, flange through hole 21, sleeve 22, nut 23, nut 26, nut 104, 105, nut 103, 104, bolt 27, screw 28, valve port 101, valve port 102, sealing surface 201, 202, 301, 302, opening and closing parts 17 Put it on the valve stem 9, fasten it with nut 23, transmit the torque with keys 24 and 25, put the sleeve 22 into the lower end hole of the valve body 16, and put the opening and closing parts 17 and the valve stem 9 into the valve body 16 together, and the valve stem One end of the 9 shaft is fixed in the hole 22 of the lower end sleeve of the valve body 16, and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com