Packing method and structure of optical fiber optical element

A technology of optical devices and packaging methods, applied in the direction of coupling of optical waveguides, etc., can solve the problems of difficult operation, affecting the stability of optical performance, increasing the overall component volume and material cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

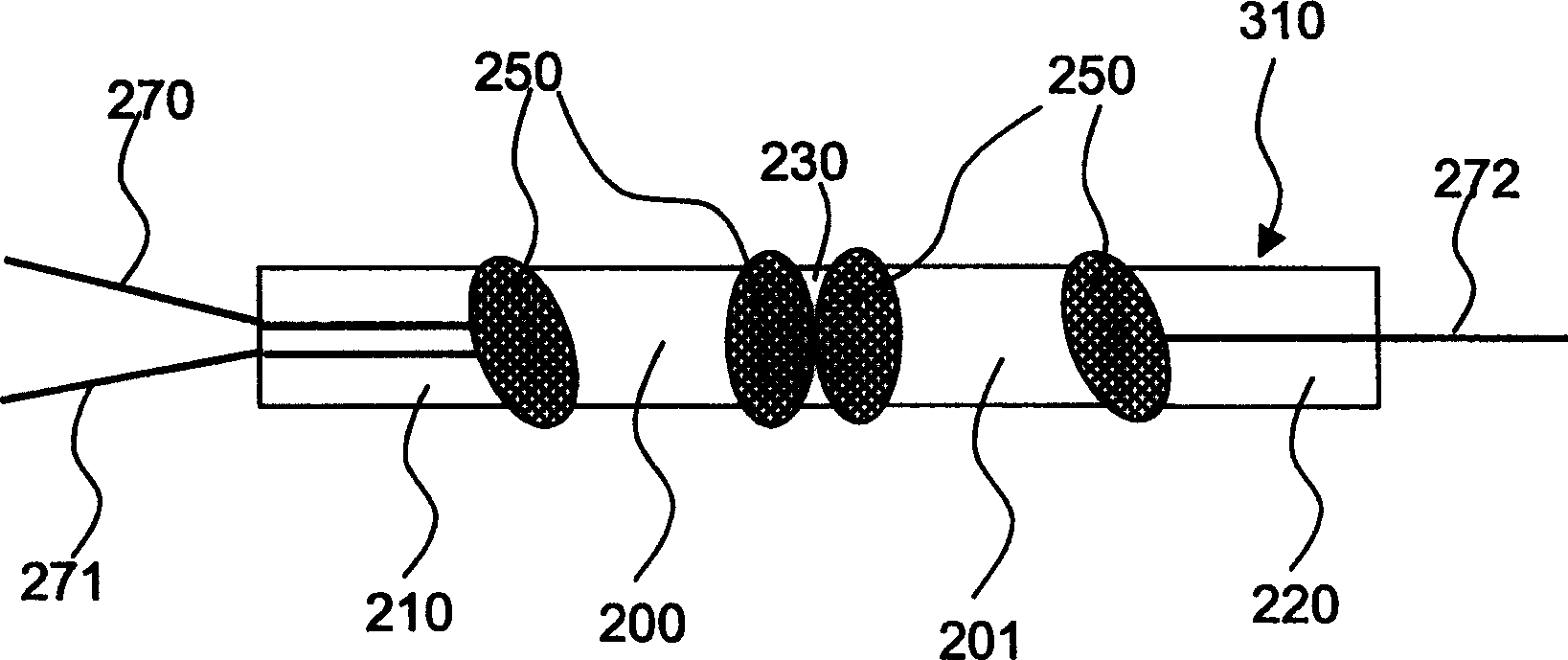

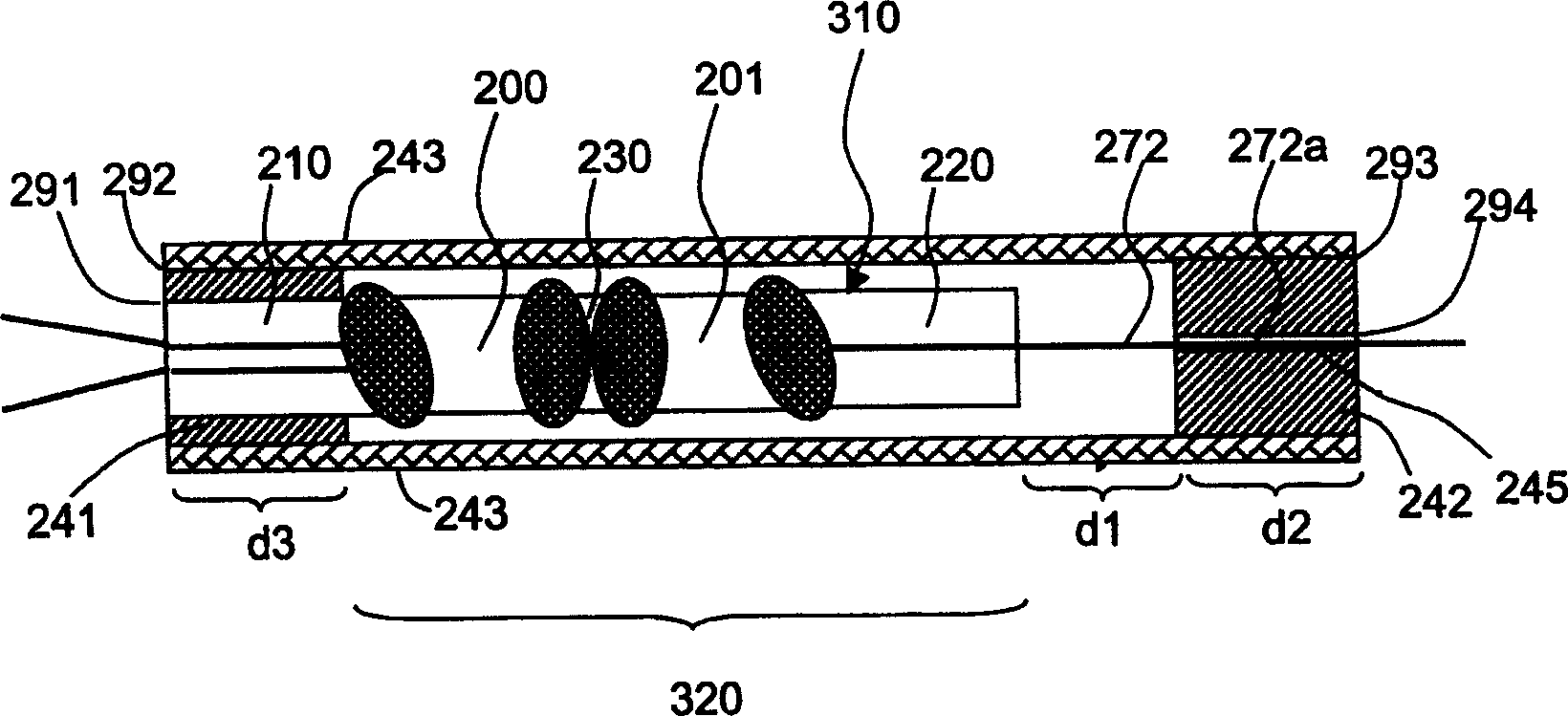

[0050] figure 2 It is a schematic diagram of a sub-combination 310 of an optical device, which is a miniaturized optical plug-and-take filter connected in series by various optical components, which includes: a double fiber pigtail 210, a first graded-index lens 200, a filter (WDM Filter ) 230, the second graded index lens 201, the single optical fiber pigtail 220 and the optical fibers 270, 271, 272, the cement 250 is used to strengthen the interface between each interface, image 3 It is a schematic diagram of the packaging of the miniaturized optical plug filter of the present invention, and the packaging method is as follows: a housing cap (housing cap) 241 with a length of d3 is inserted outside the double optical fiber pigtail 210, and its material needs to be able to completely isolate water vapor. And have appropriate thermal expansion coefficient and properties such as not easy to rust, it can be metal or glass or pottery, the gap 291 between this ring cap 241 and do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com