Integrated support system for supporting sheet metal machining

A support system, metal plate technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of not being able to use systematically, increasing the workload of skilled operators, increasing the time for internal operation setup, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The present invention will now be described in more detail with reference to the accompanying drawings and with respect to an embodiment of the integrated support system for supporting sheet metal processing of the present invention.

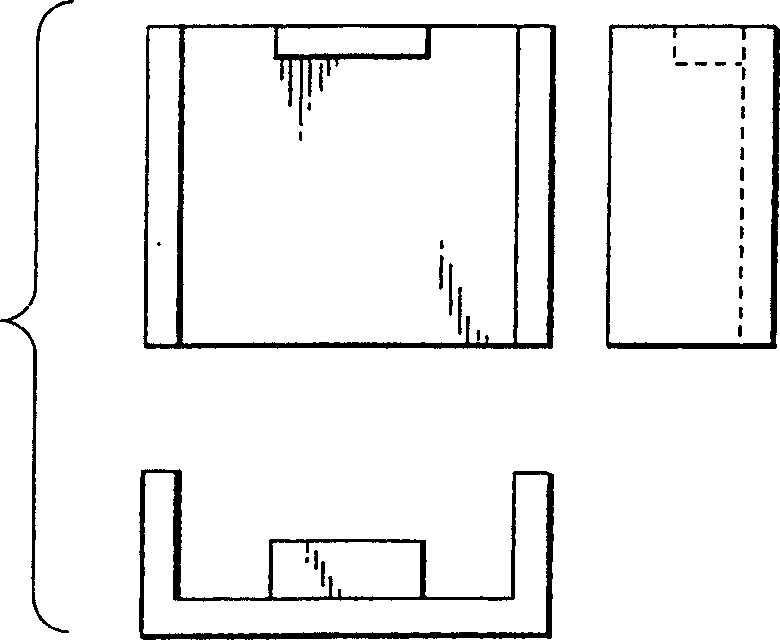

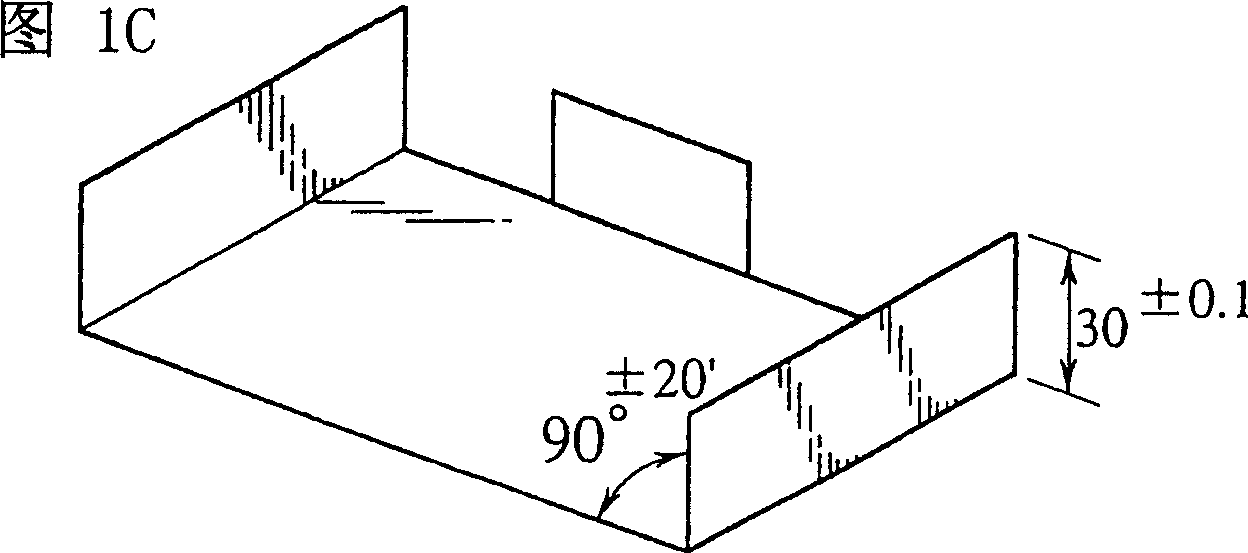

[0088] Fig. 2 is a block diagram of the functional arrangement of an embodiment of the integrated support system for supporting sheet metal processing of the present invention. As shown in Figure 2, the embodiment of the integrated support system for supporting sheet metal processing of the present invention can be divided into sheet metal processing information storage device 700 according to functions, design site A and processing site B, and the latter two share sheet metal processing information Storage device 700.

[0089] The design site A includes a CAD (Computer Aided Design) unit 100 for receiving three-view and other design data, and generating derivation view data, such as for sheet metal processing, and a processing simulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com