Parallel axes gear reducer and gear driven motor

A technology of gear reduction and parallel shafts, which is applied to gear transmissions, transmissions, belts/chains/gears, etc., can solve the problems of increased size, increased weight, and increased costs, and achieve low cost and ensure assembly Ease of use, the effect of avoiding the complexity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

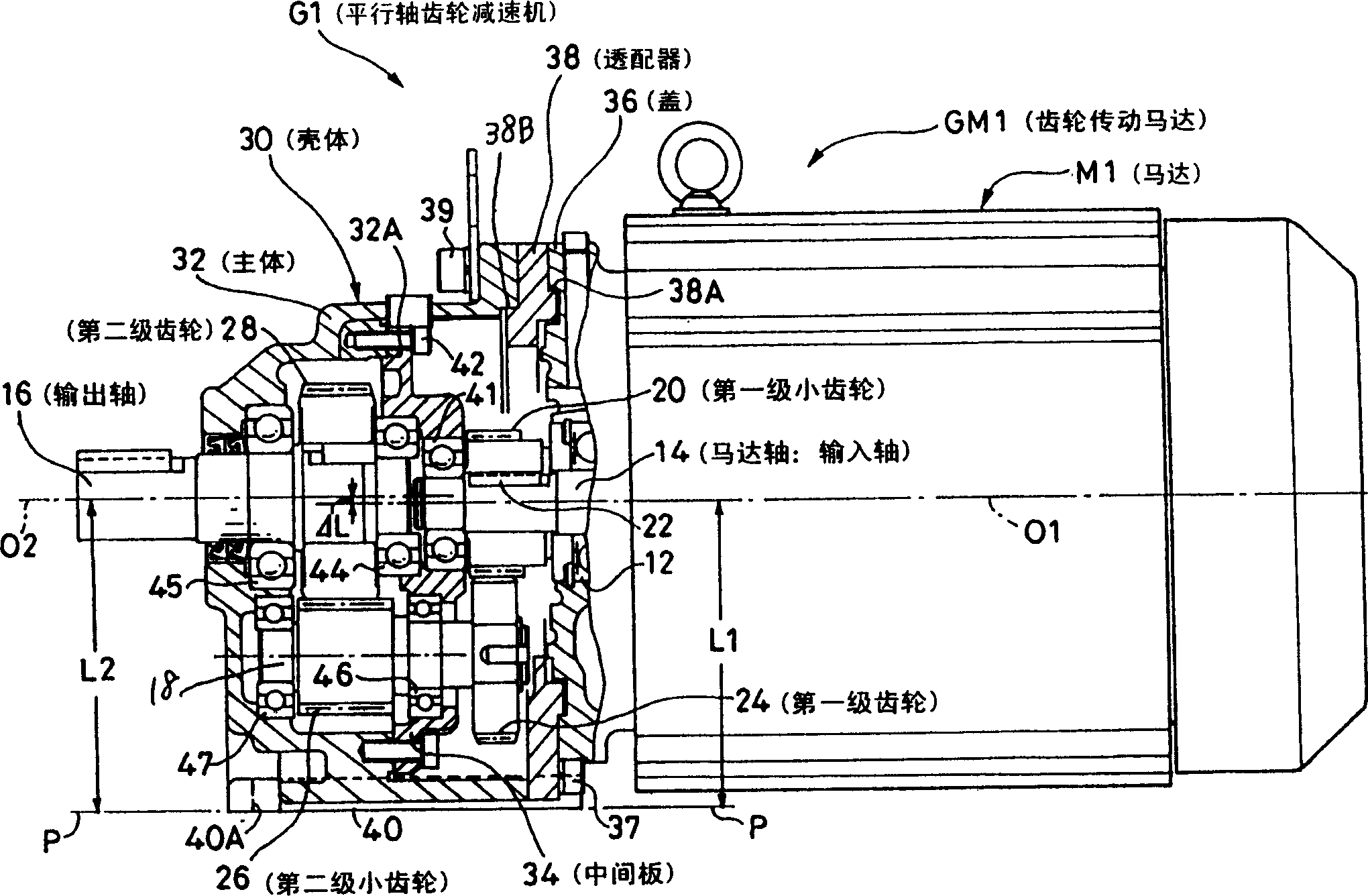

[0023] figure 1 An example of the geared motor GM1 according to the embodiment of the present invention is shown.

[0024] This geared motor GM1 is a device that integrates a motor M1 and an external engagement type parallel shaft gear reducer G1.

[0025] The motor M1 is provided with a motor shaft 14 rotatably supported by a pair of bearings (only the bearings 12 on the side of the parallel shaft gear reducer G1 are shown in the drawing). The front end of the motor shaft 14 is close to the inside of the parallel shaft gear reducer G1, and also serves as an input shaft of the parallel shaft gear reducer G1. Thus, the motor shaft 14 in this embodiment is appropriately referred to as the input shaft 14 for convenience.

[0026] The parallel shaft gear reduction mechanism G1 includes the input shaft 14 and the output shaft 16 arranged in parallel with the inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com