Solar battery automatic coating system

A solar cell, automatic technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problem of no solar cell square array automatic patching system, etc., to improve labor production efficiency, reduce production costs, and reduce the effect of fragmentation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

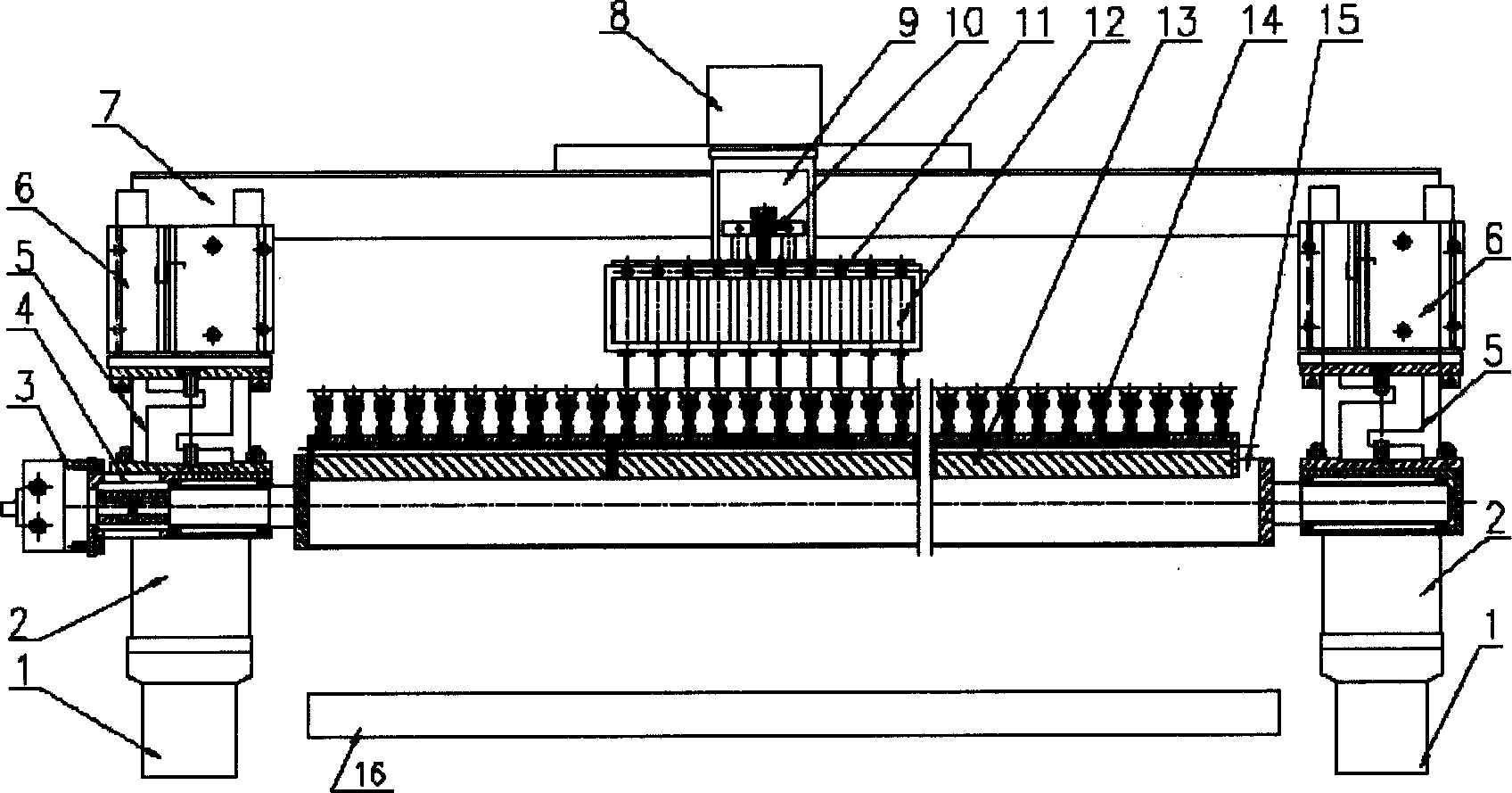

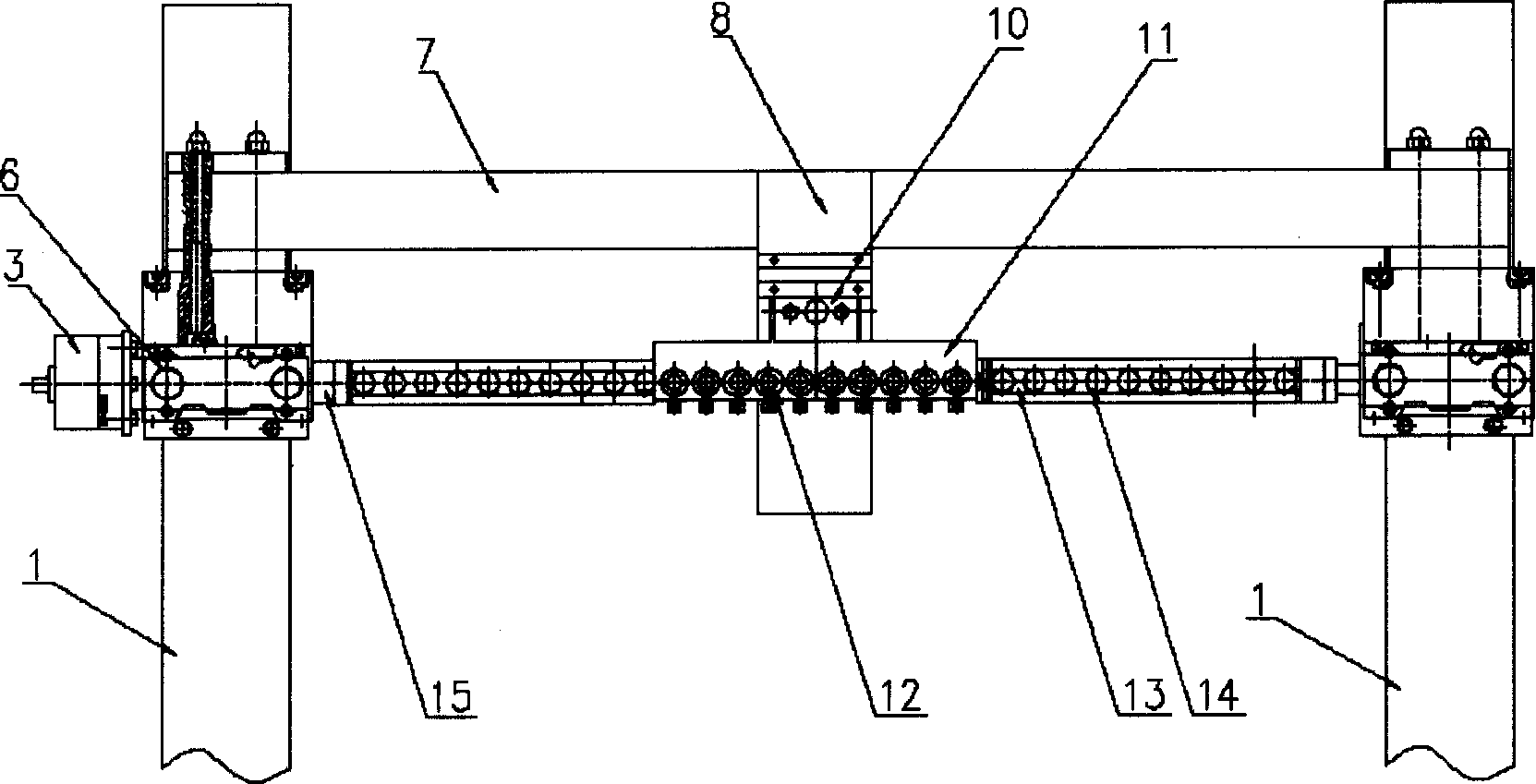

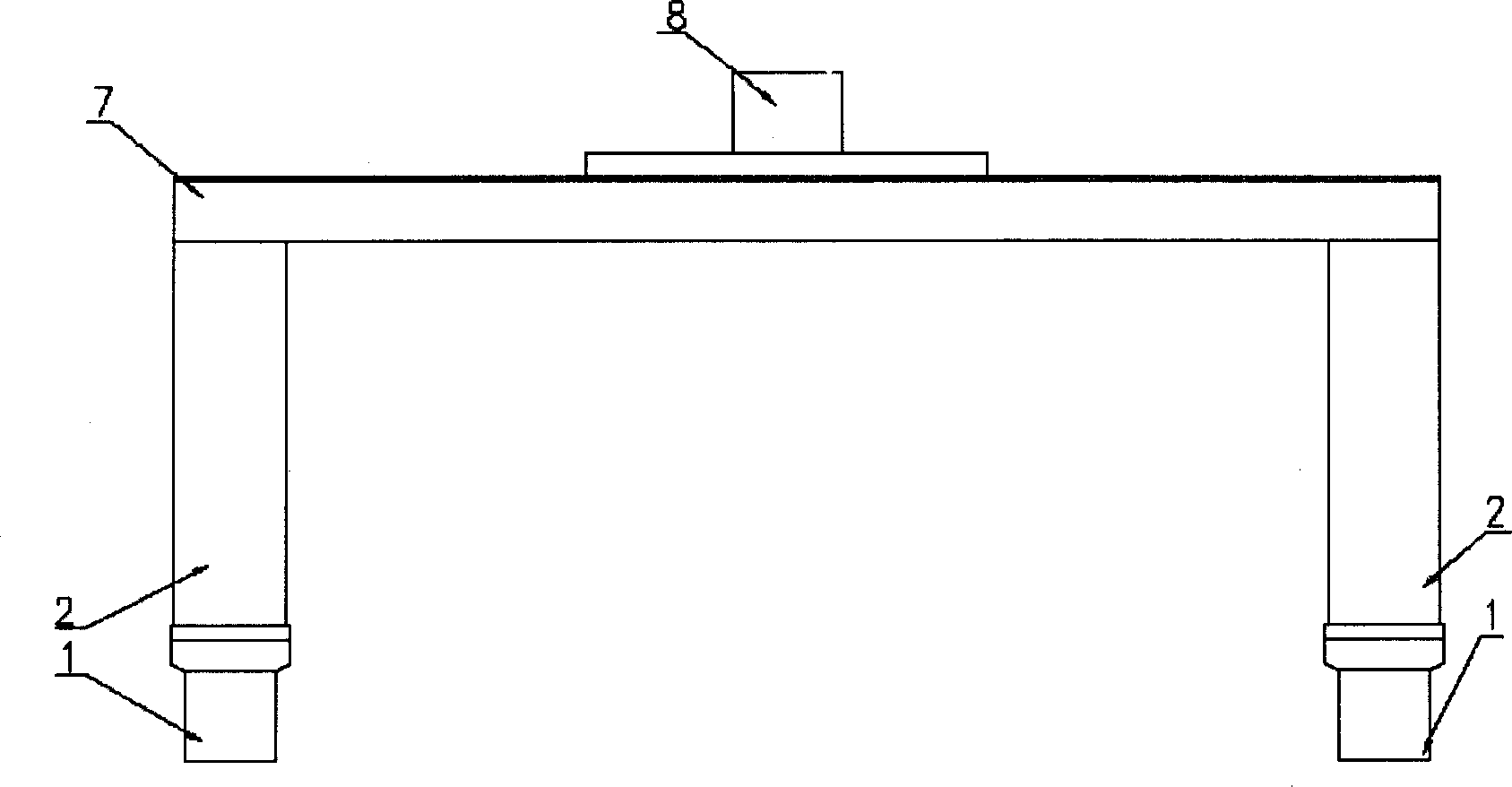

[0021] The overall structure of the solar cell automatic placement system of the present invention is as follows: figure 1 (main view), figure 2 (top view), as shown, it is guided by the positioning mechanism ( image 3 ), cloth sticking mechanism ( Figure 4 ), dispensing mechanism ( Figure 5 )composition.

[0022] figure 1 It is the front view of the overall structure of the solar cell automatic placement system. The bottom of the figure is two X-guiding rails 1, and a support beam 2 is installed on the slider of each X-guiding rail 1. On the top of the two support beams 2 A Y-guiding rail 7 is fixed, and a Z-guiding rail 8 is installed on the slider of the Y-guiding rail 7; an executive cylinder 6 is respectively fixed in front of the upper part of the two support beams 2, and a puller is respectively connected and fixed below the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com