Inverter of washing machine and inverter of washing machine/dryer

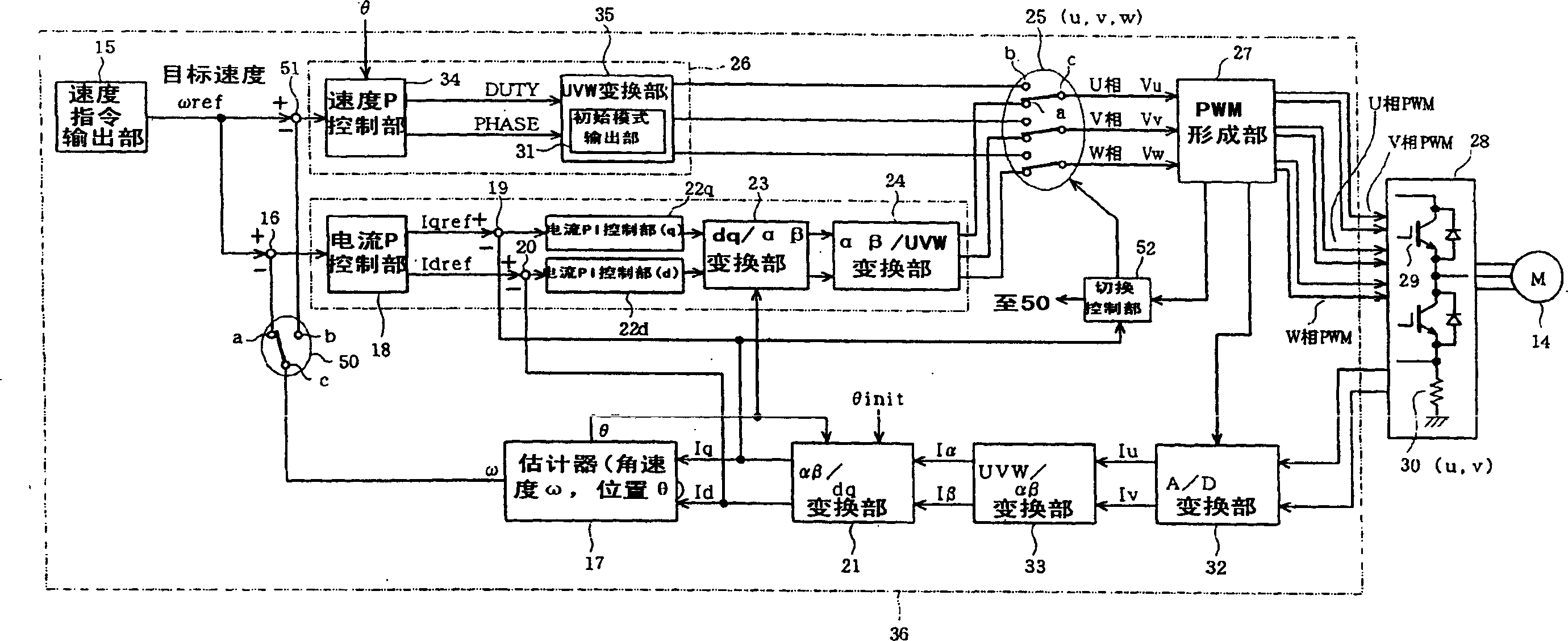

A laundry dryer and inverter technology, which is applied to the control device of the washing machine, washing machine appliances, washing devices, etc., can solve the problems of increasing the power supply current, reducing the efficiency of the motor, and increasing the size of the inverter circuit and motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

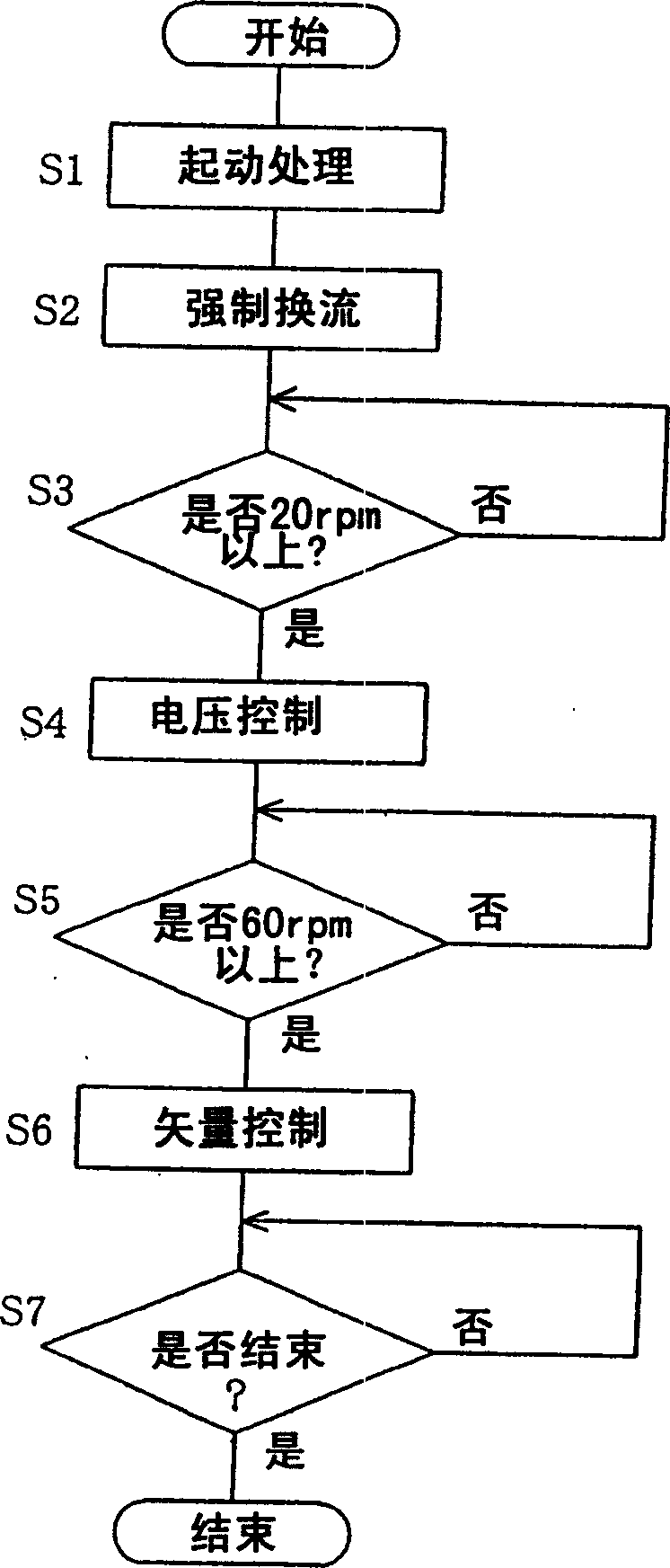

Method used

Image

Examples

Embodiment Construction

[0027] best practice

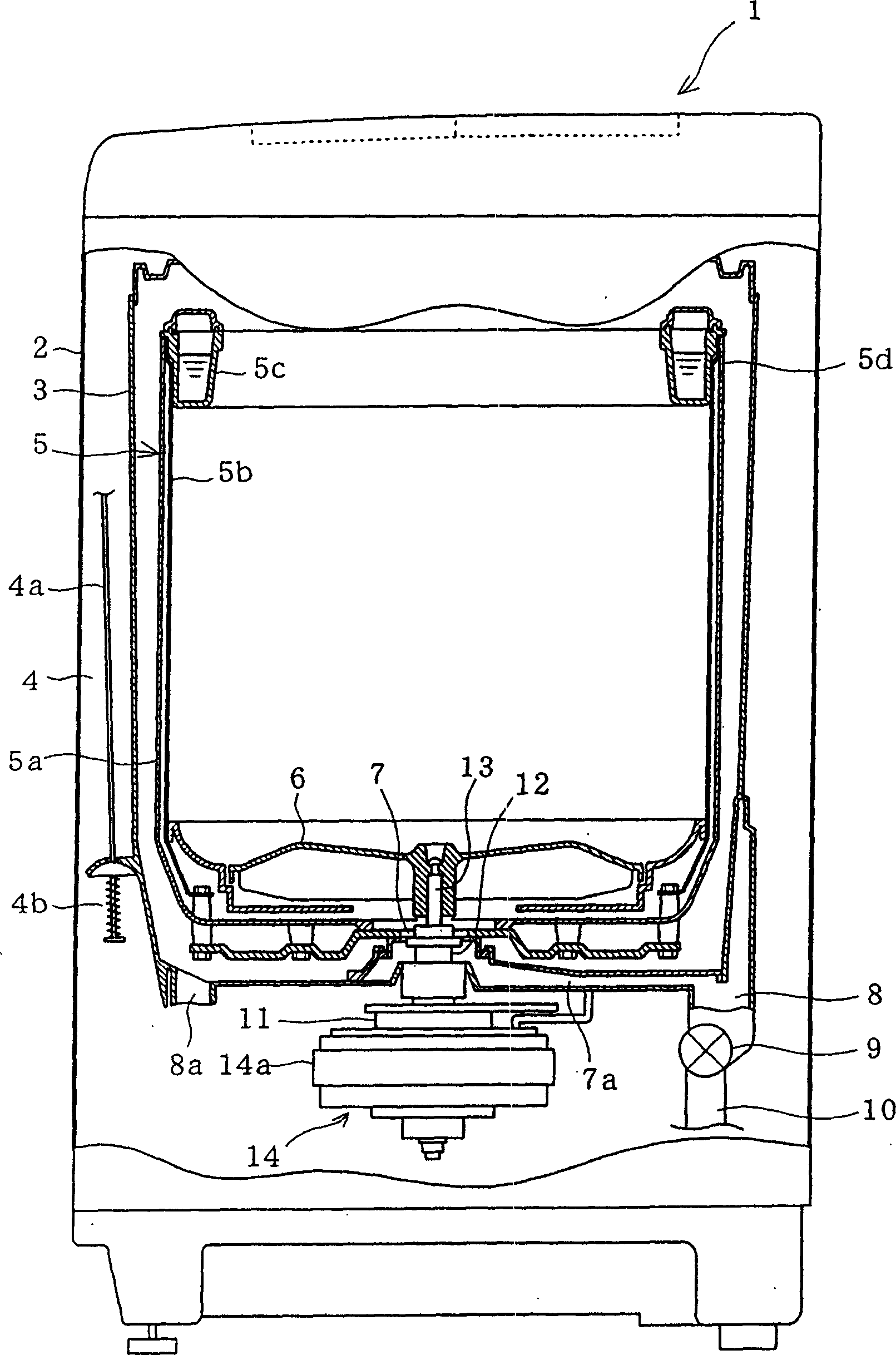

[0028] Below, refer to Figure 1 to Figure 10 Example 1 in which the present invention is applied to a vertical shaft fully automatic washing machine will be described. first, figure 2 It is a longitudinal sectional view showing the overall composition of the fully automatic washing machine 1 . The outer box 2 is formed into a rectangle as a whole, and the water tank 3 is elastically supported by 4 groups (only 1 group is shown in the figure) anti-vibration mechanism 4 inside it. Anti-vibration mechanism 4 comprises the suspension rod 4a that upper end is fixed on the top in outer case 2 and the shock absorber 4b that is installed on the other end of this suspension rod 4a for making vibration attenuation, and is made up of these two parts. The water tank 3 is elastically supported by these anti-vibration mechanisms 4, and the vibration generated during the washing operation is prevented from being transmitted to the outer case 2 as much as possible....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com