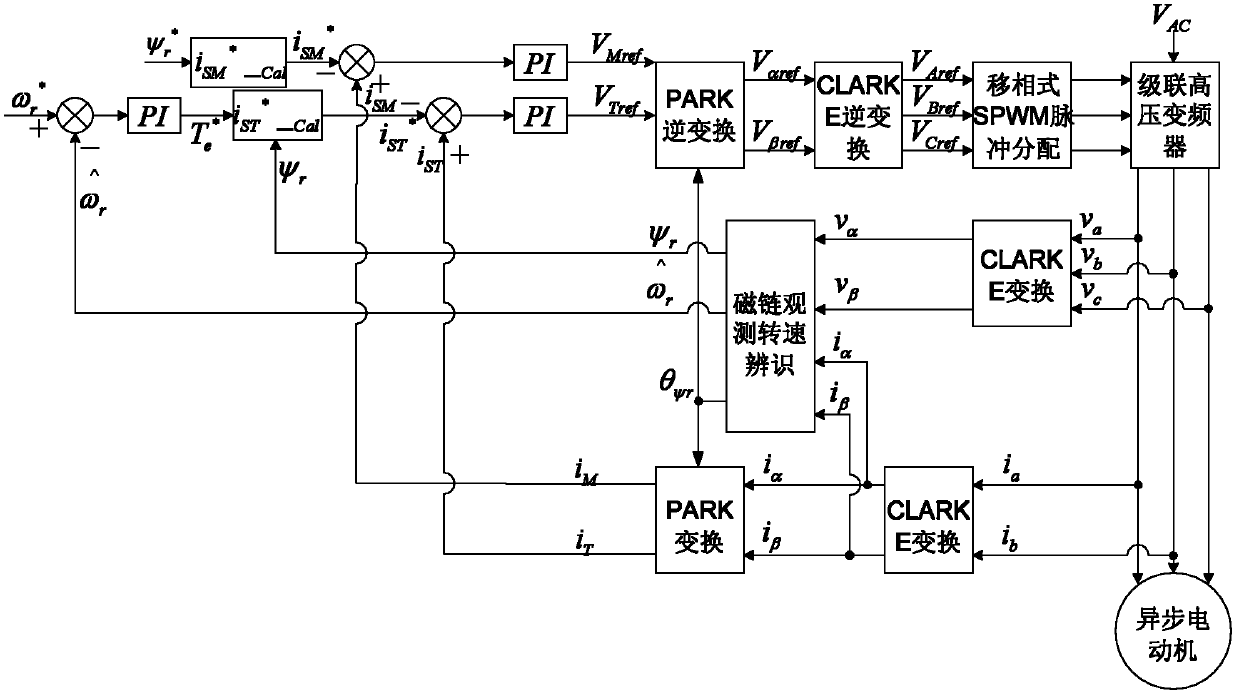

Speed sensorless vector control method on basis of cascaded high voltage inverter

A speed sensorless, high-voltage frequency converter technology, applied in vector control systems, control systems, control generators, etc., can solve the problem of being easily affected by the environment, the measurement accuracy of the speed encoder, and the simplicity of the asynchronous motor speed control system, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

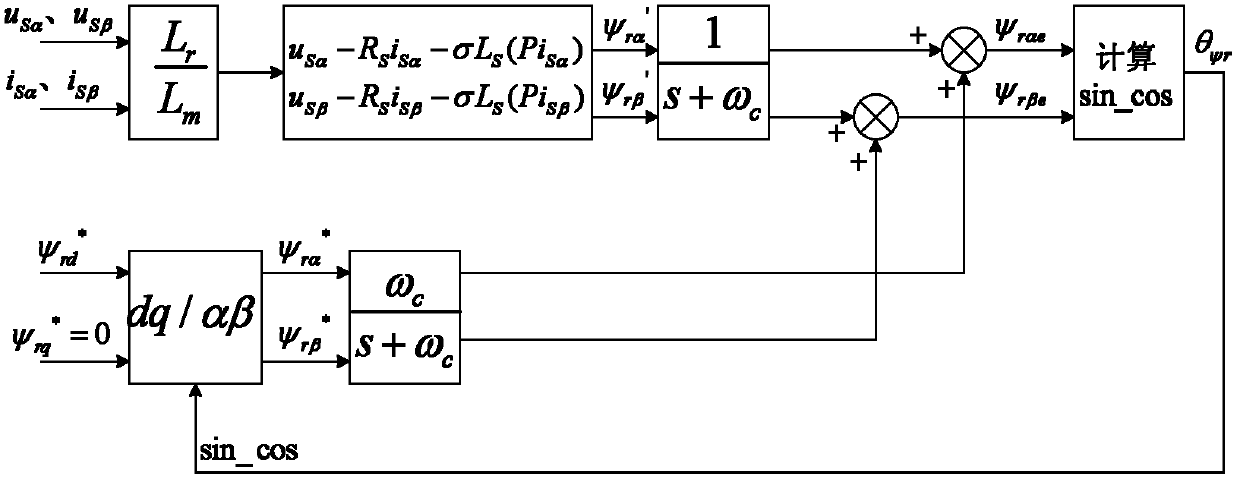

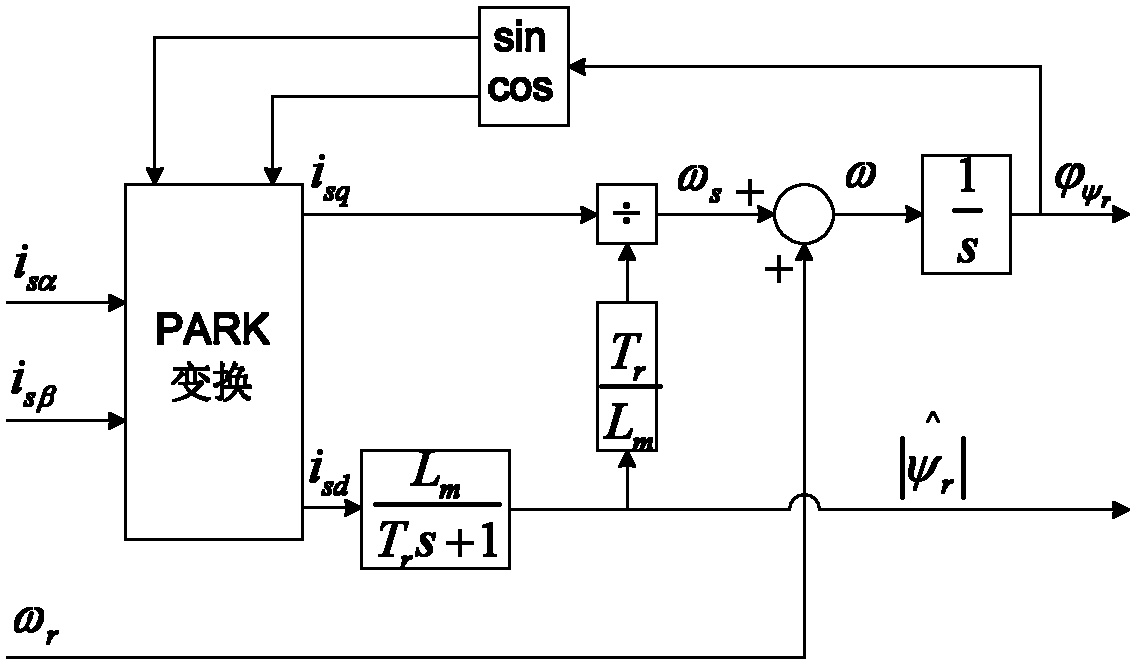

[0033]The invention is a speed sensorless vector control method for cascaded high-voltage frequency converters oriented according to the rotor magnetic field. The coordinate axes M and T are set to rotate at a synchronous speed ω, and the M axis is specified to be along the total flux vector ψ of the rotor. r At this time, the mathematical model of the asynchronous motor on the two-phase (M, T) rotating coordinate system:

[0034] u SM u ST 0 0 = R s + L s p ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com