Isothermal container discharge process experimental apparatus

An experimental device and container technology, which is applied in the direction of mass flow measurement device, fluid flow detection by measuring differential pressure, indirect mass flow meter, etc., can solve the problem of inability to measure the flow characteristics and deviation of pneumatic components, and achieve low gas source capacity requirements , less air consumption and shorter measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

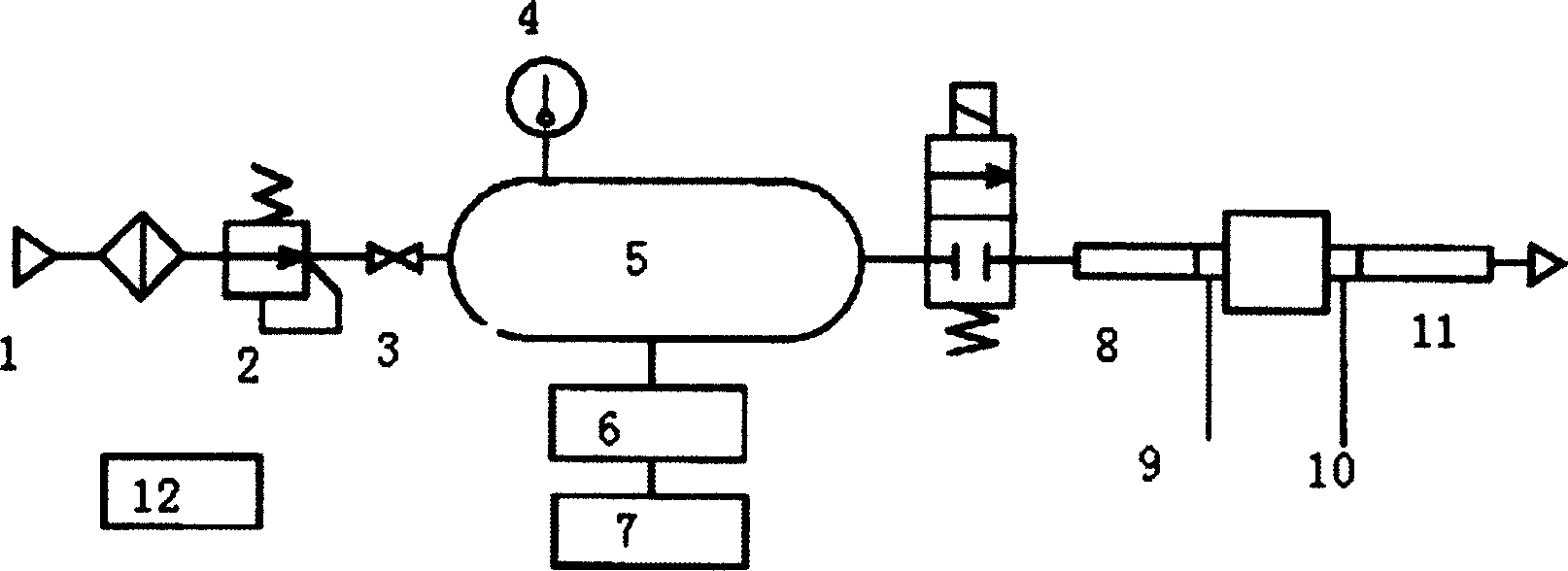

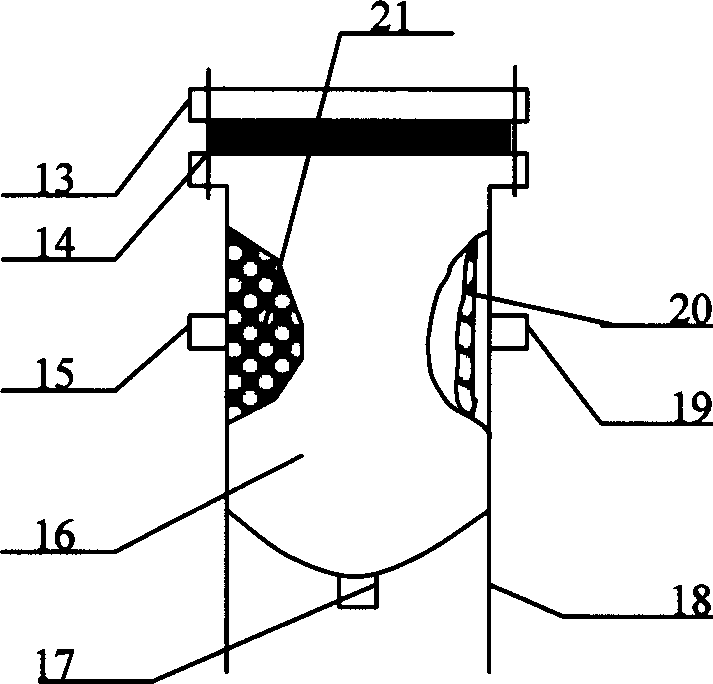

[0013] like figure 1 As shown, the experimental device of the isothermal vessel release method of the present invention includes: a gas source 1, a pressure reducing valve 2, a stop valve 3, a temperature sensor 4, an isothermal vessel 5, a pressure sensor 6, a data recorder 7, a barometer 8, and an upstream rectifier tube. 9. The upstream rectifier pipe joint 10 , the downstream rectifier pipe joint 11 , and the downstream rectifier pipe 12 . The connection relationship is as follows: one end of the gas source 1 is connected to the inlet of the pressure reducing valve 2, and the other end is connected to the stop valve 3; the other end of the stop valve 3 is connected to the isothermal container 5, and the isothermal container 5 is connected to the upstream rectifier pipe 9 at the same time. The other end of the upstream rectifier tube 9 is connected to the air inlet of the component under test through the upstream rectifier tube joint 10, the exhaust port of the measured com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com