Synchronous characterization method for orthotropic elastic constant virtual field of high-speed impact special-shaped piece

A high-speed impact, orthotropic technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve problems such as difficulty in ensuring the global and accurate representation of anisotropic parameters, and achieve the goal of improving flexibility, simplifying experimental equipment, and breaking through conditional constraints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

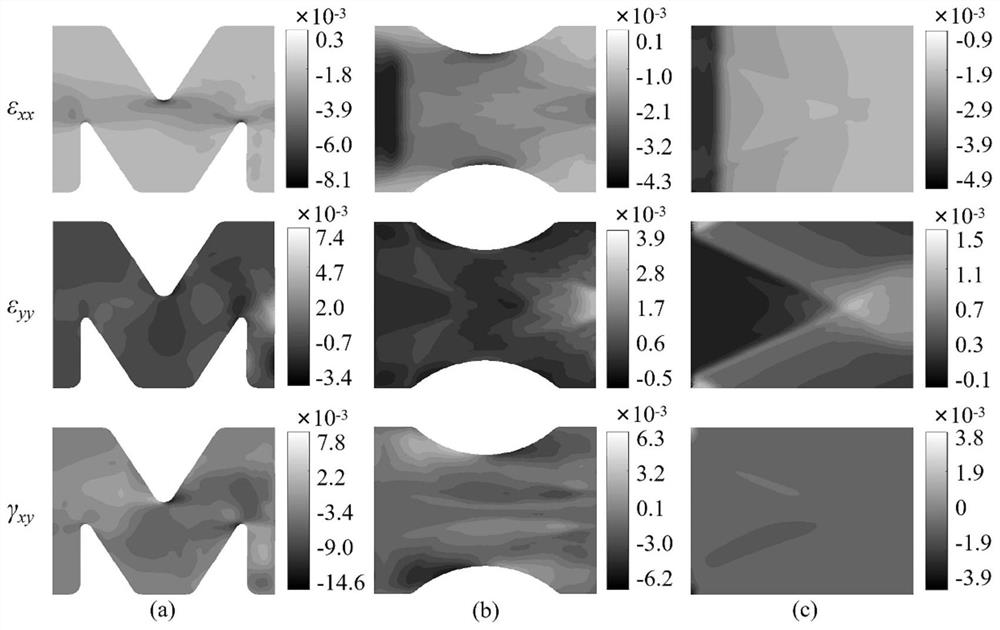

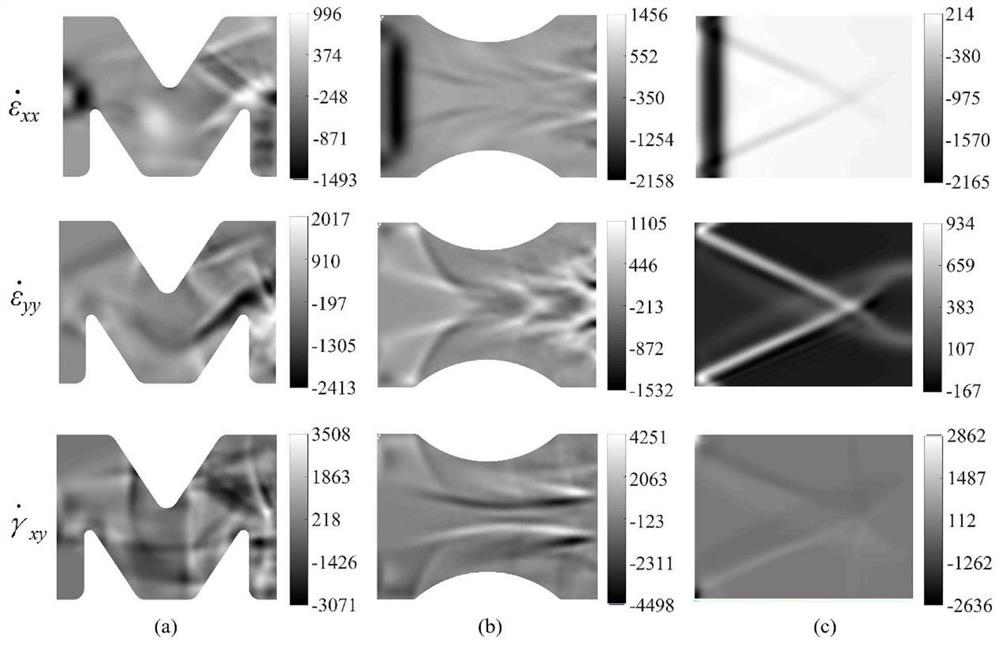

[0061] Example 1: Using finite element software to carry out numerical simulation of high-speed impact experiments, setting material constitutive model and model parameters, simulating one-way high-speed impact loading of specimens, and deriving the strain field, strain rate field and Acceleration field simulation data, substitute the simulation data into the anisotropic elastic constant dynamic virtual field The characterization program identifies the orthotropic elastic constants based on the simulated data, and compares the parameter characterization results with the reference values input into the model to verify the accuracy of the method.

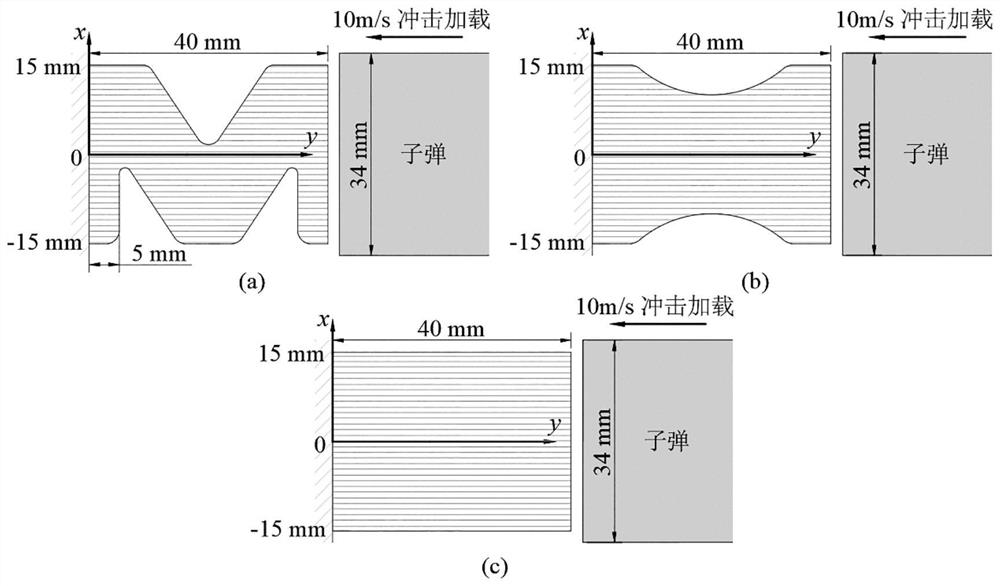

[0062] Step 1: Design the high-speed impact loading configuration of special-shaped specimens in the finite element software Part of the material is removed from the rectangular plate, so that the specimen can obtain structural features such as notches and corners. Under the high-speed impact of bullets, the specimen can produce s...

Embodiment 2

[0100] Example 2: Experimental method for synchronous characterization of orthotropic elastic constant virtual field based on high-speed impact of special-shaped parts, the selected material is long fiber reinforced resin matrix composite material; the difference between this example and Example 1 is that the long fiber reinforced resin matrix composite material is tested The deformation field and its corresponding strain field, strain rate field and acceleration field under the condition of high-speed impact of the workpiece are obtained by ultra-high-speed imaging system and digital image correlation operation. Other steps, such as specimen configuration, loading process, data substitution, virtual Field selection, program operation, etc. are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com