Combined powder selector with double wheel differential motion

A technology of powder classifier and roulette, which is applied in the direction of solid separation, separating solid from solid by air flow, chemical instruments and methods, etc. It can solve the problems of inability to operate at differential speed, complex system, and low efficiency of powder selection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

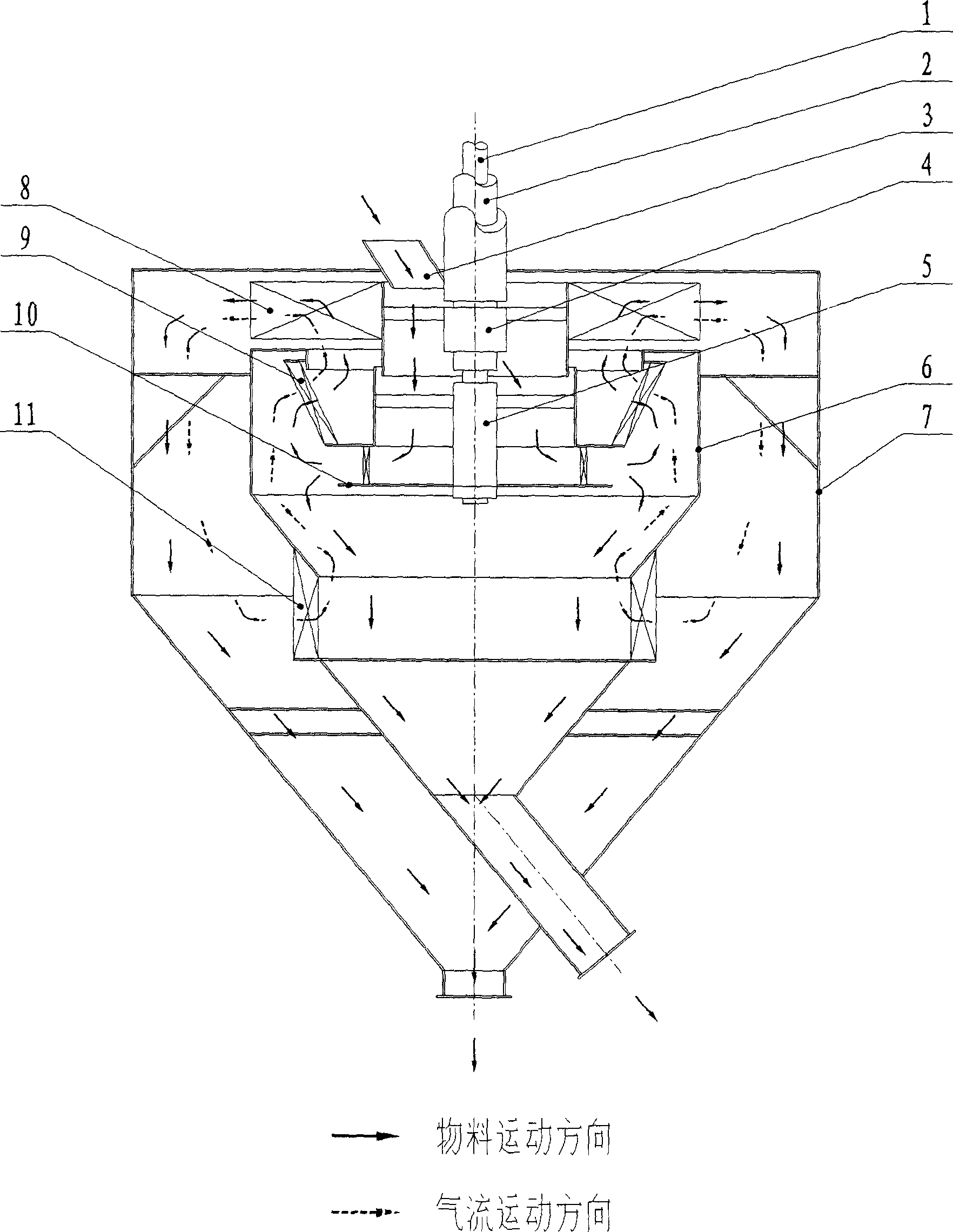

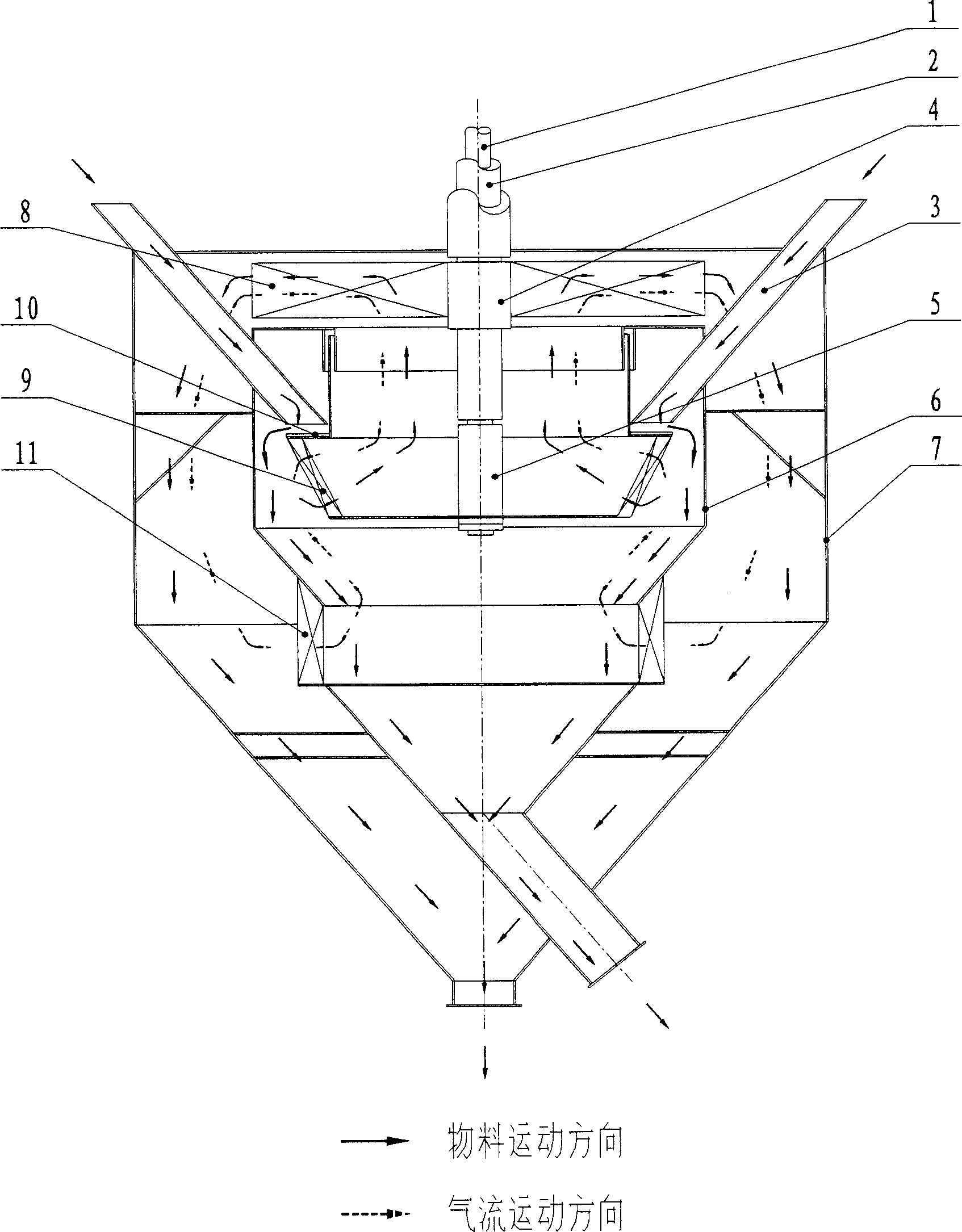

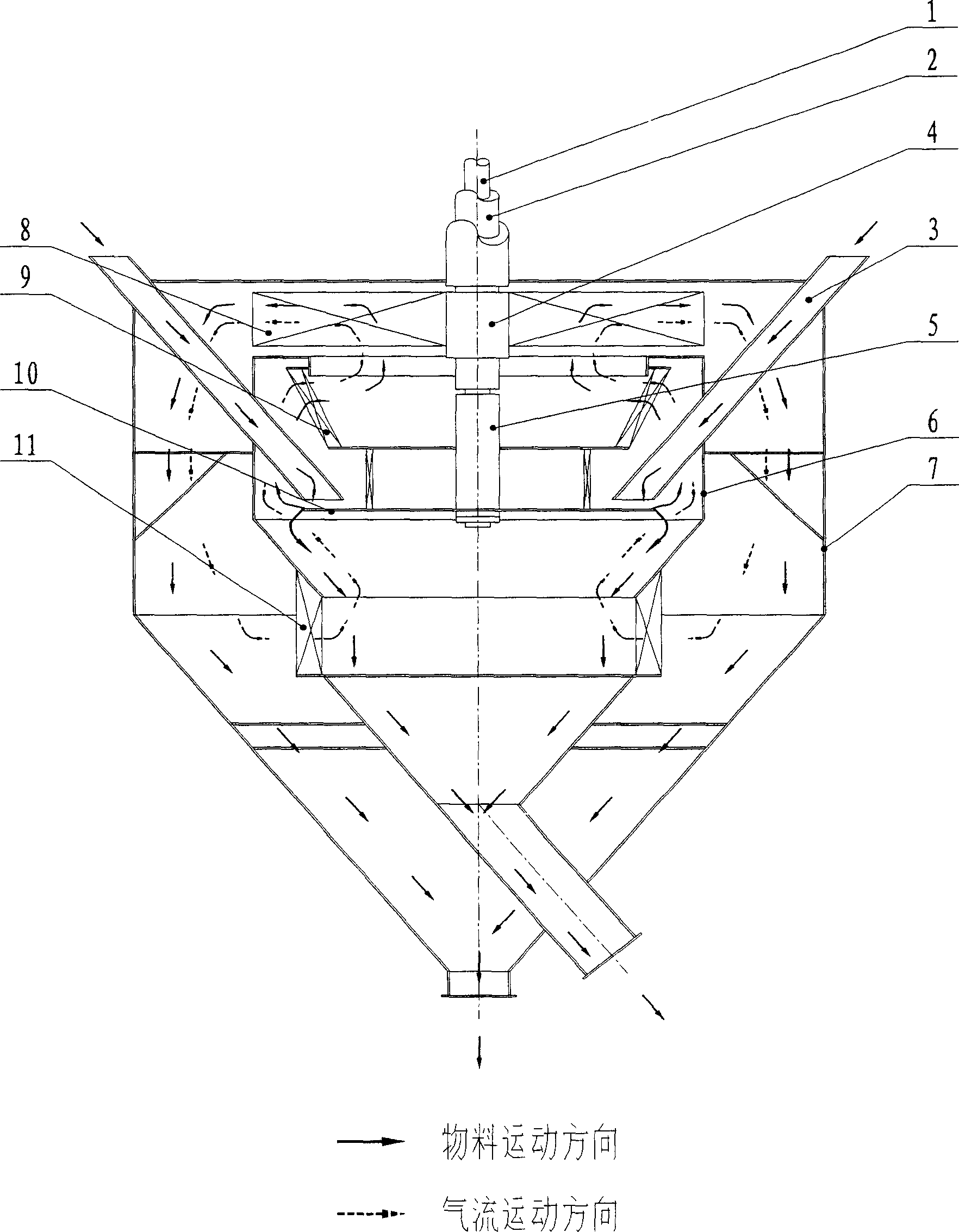

[0009] The implementation of the present invention mainly contains the following alternative schemes

[0010] The first type is called the basic type, the centrifugal wind wheel (4) is installed on the shaft (2), the classification wheel (5) is installed on the shaft (1), the shaft (2) is a hollow shaft, and the shaft (1) passes through the bearing It is sleeved in the shaft (2) to realize differential transmission. The feed inlet is installed near the middle of the powder classifier and feeds the material to the center of the centrifugal wind wheel. This feeding method requires at least one circle of retaining ring on the multi-layer rotating wheel to prevent the material from going inward without the spreader. The outside directly rushes into the wind path and causes rough running. This scheme can also be placed on the bottom of the powder classifier with the transmission system. At this time, the classification wheel (5) needs to be installed on the hollow outer shaft (2),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com