Assembling structure of igniter

A technology of igniter and structure, applied in igniter with fuel, combustion ignition, combustion method, etc., can solve problems such as complex design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

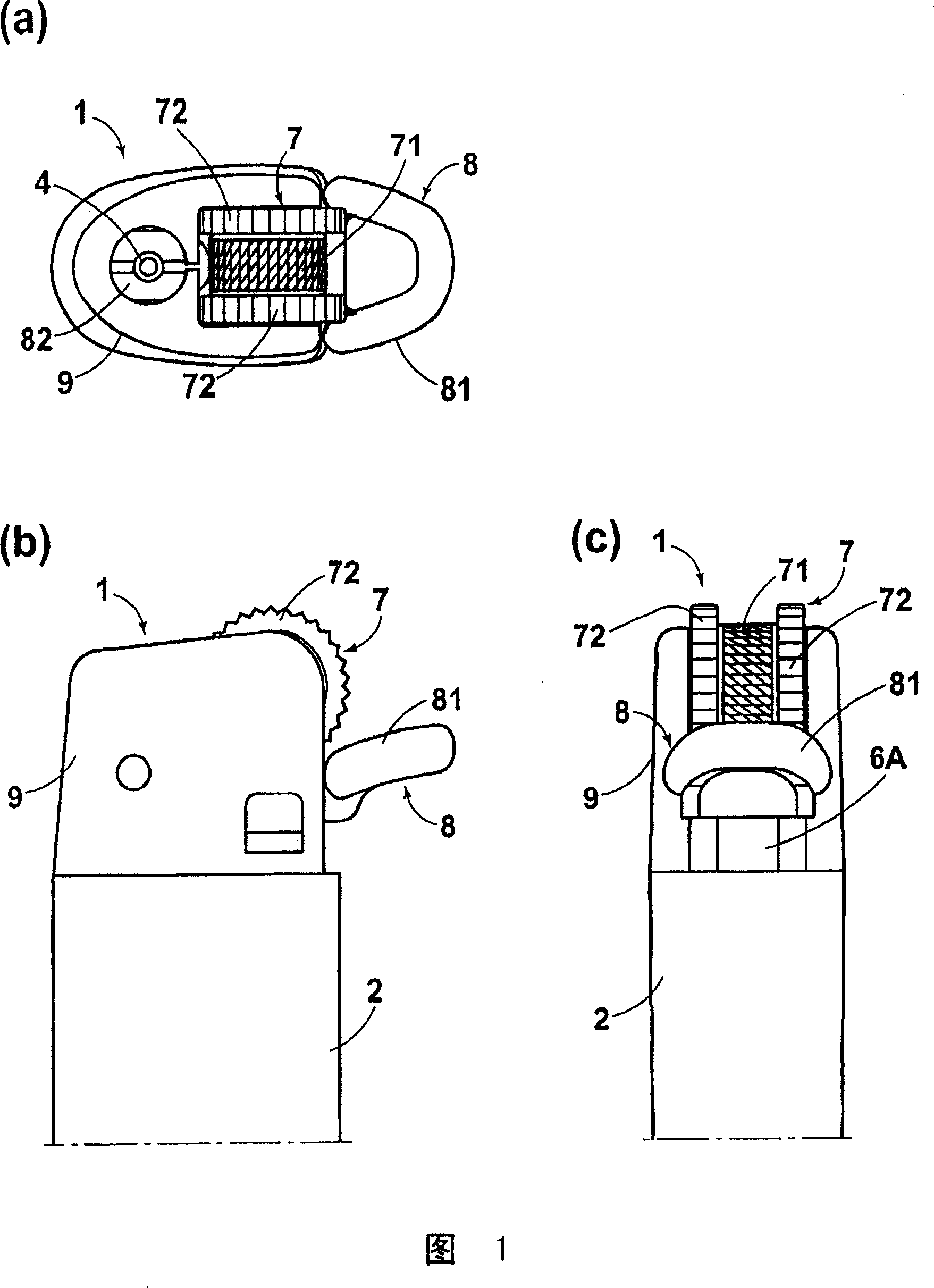

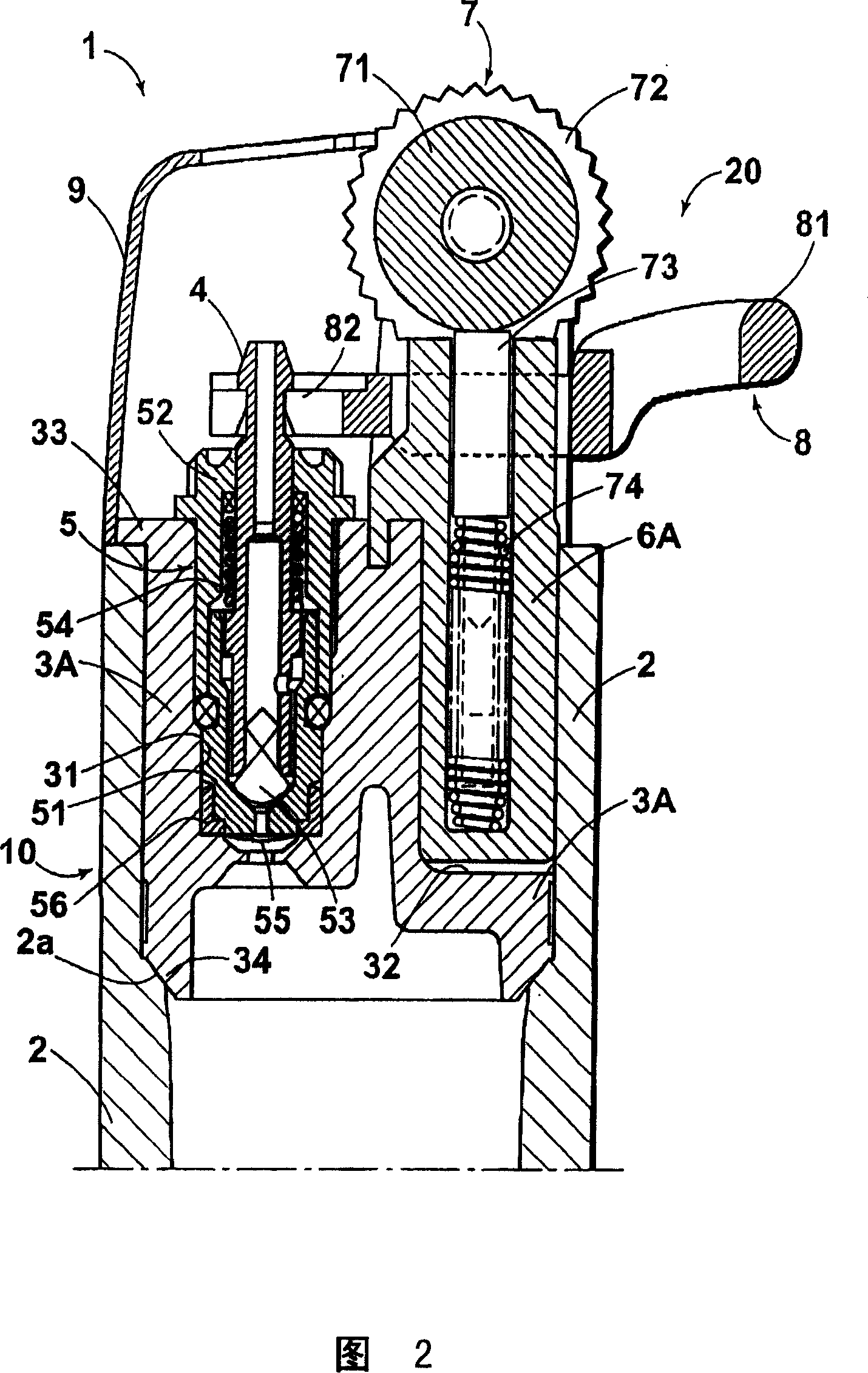

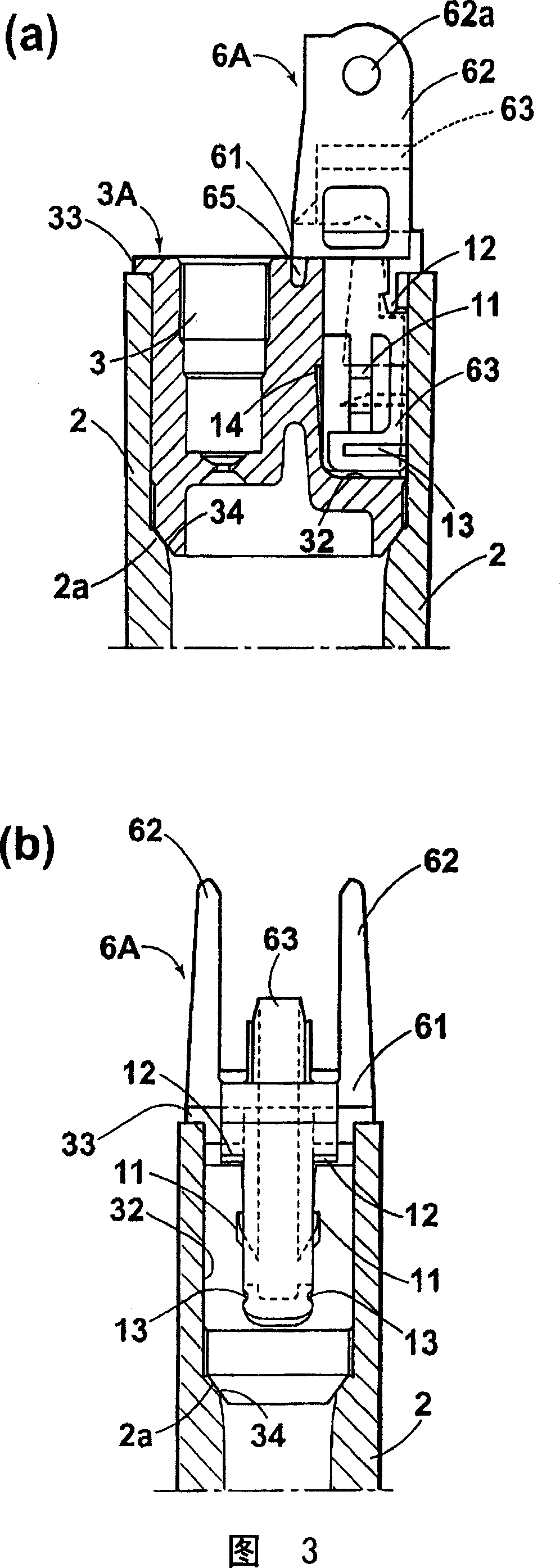

[0045] This embodiment is a flint type igniter, figure 1 It is a top view (a), a side view (b), and a rear view (c) showing the appearance of the igniter. figure 2 It is a central longitudinal sectional side view of the igniter. image 3 It is a partially cutaway side view (a) and a partially cutaway rear view (b) showing the assembled state of the bracket. Figure 4 and Figure 5 is a part diagram, Figure 4 It is the top view (a), central sectional side view (b), rear view (c) of the upper cover of the box, Figure 5 It is a top view (a), a central sectional side view (b), a side view (c), a rear view (d), a sectional rear view (e), and a bottom view (f) of the bracket. In addition, in the following description, based on how the igniter is used, the figure 1 In (b), the left side is referred to as the front, and the right side is referred to as the rear.

[0046] Such as figure 2 As shown, the igniter 1 is formed by assembling a lower assembly body 10 and an upper a...

no. 2 Embodiment approach

[0070] This embodiment is also a flint type igniter, Image 6 It is a partially cutaway side view (a) and a partially cutaway rear view (b) showing the assembled state of the bracket. Figure 7 and Figure 8 is a part diagram, Figure 7 It is the top view (a), central sectional side view (b), rear view (c) of the upper cover of the box, Figure 8 It is a top view (a), a central sectional side view (b), a side view (c), a rear view (d), a sectional rear view (e), and a bottom view (f) of the bracket. The basic structure of the igniter 1 of flint formula and figure 1 The igniter is the same, and although the structure of the assembly hook of the box top cover 3B and the bracket 6B is different, the same reference numerals are assigned to the common parts, and the description thereof will be omitted.

[0071] The assembly and fixing structure of the box upper cover 3B and the bracket 6B of the present embodiment is as follows: Image 6 As shown, it is composed of the 5th and...

no. 3 Embodiment approach

[0077] This embodiment is also a flint type igniter, Figure 9 It is a partially cutaway side view (a) and a partially cutaway rear view (b) showing the assembled state of the bracket. Figure 10 and Figure 11 is a part diagram, Figure 10 It is the top view of the box cover (a), the central sectional side view (b), and the sectional rear view of the bracket assembly hole (c), Figure 11 It is a top view (a), a central sectional side view (b), a side view (c), a rear view (d), a sectional rear view (e), and a bottom view (f) of the bracket. The basic structure of the igniter 1 of flint formula and figure 1 The igniter is the same, and although the assembly hook structure of the case upper cover 3C and the bracket 6C is different, the same reference numerals are assigned to the common parts as described above, and the description thereof will be omitted.

[0078] The assembly and fixing structure of the case upper cover 3C and the bracket 6C of the present embodiment is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com