Mask frame assembly for depositing a thin layer of an electroluminescent device and method for depositing a thin layer

A technology of mask components and mask frames, which is applied in electroluminescent light sources, electric solid-state devices, semiconductor devices, etc., and can solve problems such as different colors, increased production costs, and increased number of masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

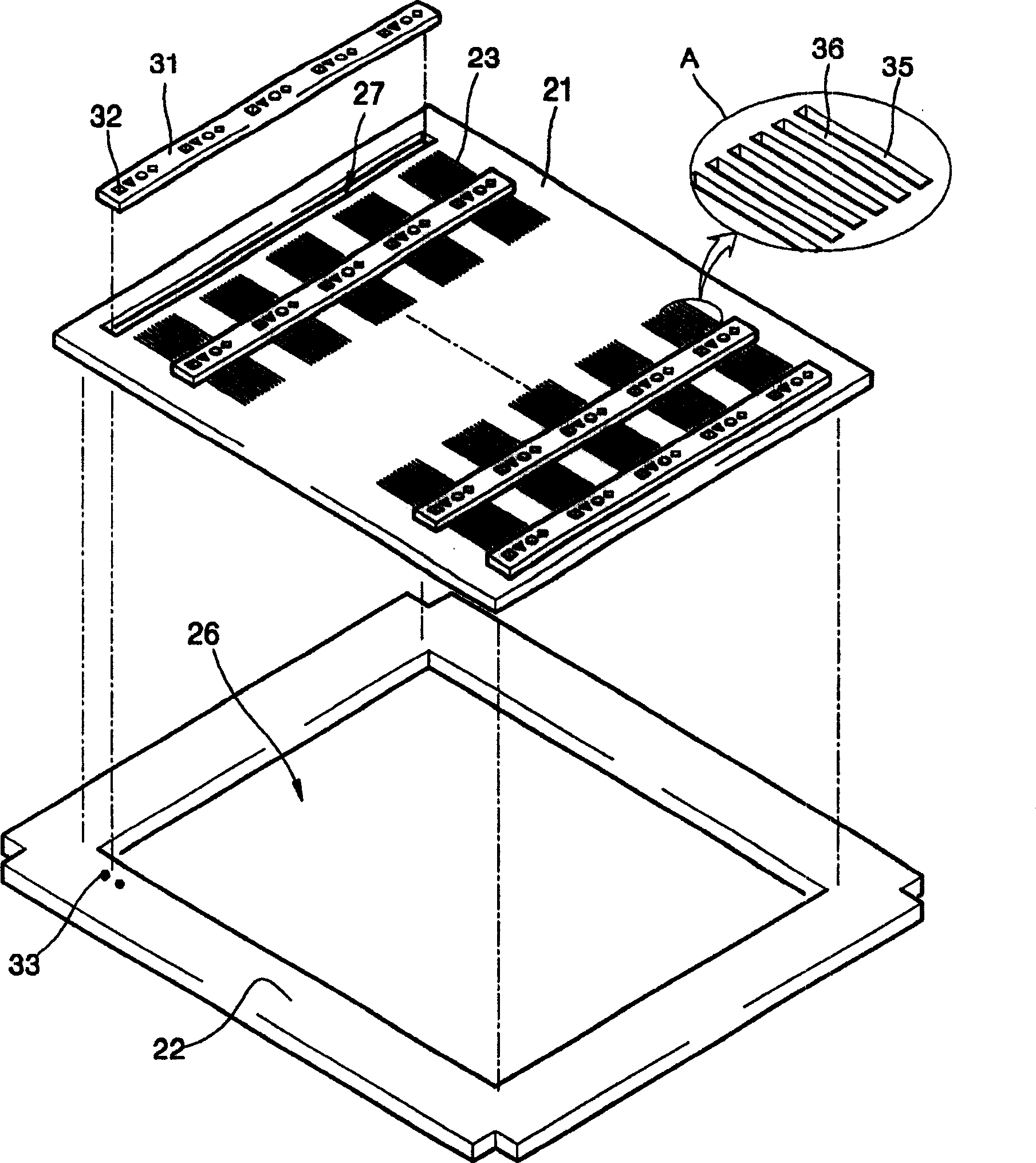

[0024] Such as figure 2 As shown, the mask frame assembly of the present invention can include a main mask 21, which is formed with a pattern 23 corresponding to each required unit cell; icon masks 31, which are respectively arranged on the main mask 21 and a mask frame 22 formed with openings 26 corresponding to the main mask 21 . As shown, mask frame 22 may be attached to mask 21 and icon mask 31 .

[0025] The main mask 21 may be formed with a large number of patterns 23 and a large number of openings 27 . Each pattern 23 may be formed as a unitary body. As can be seen from the enlarged view of the pattern 23 shown as "A", the pattern 23 may include a large number of parallel slits 35, all of which may be formed by perforating (or patterning) the master mask 21, and as a result, A number of strips 36 are also formed between the slits 35 . Organic substances can be deposited through the slits 35 on a substrate (not shown) disposed under the master mask 21 . Master mask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com