Elastic surface-wave device

A surface acoustic wave and range technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of inaccessibility, large reflection coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be clarified by describing specific examples of the surface acoustic wave device of the present invention with reference to the drawings.

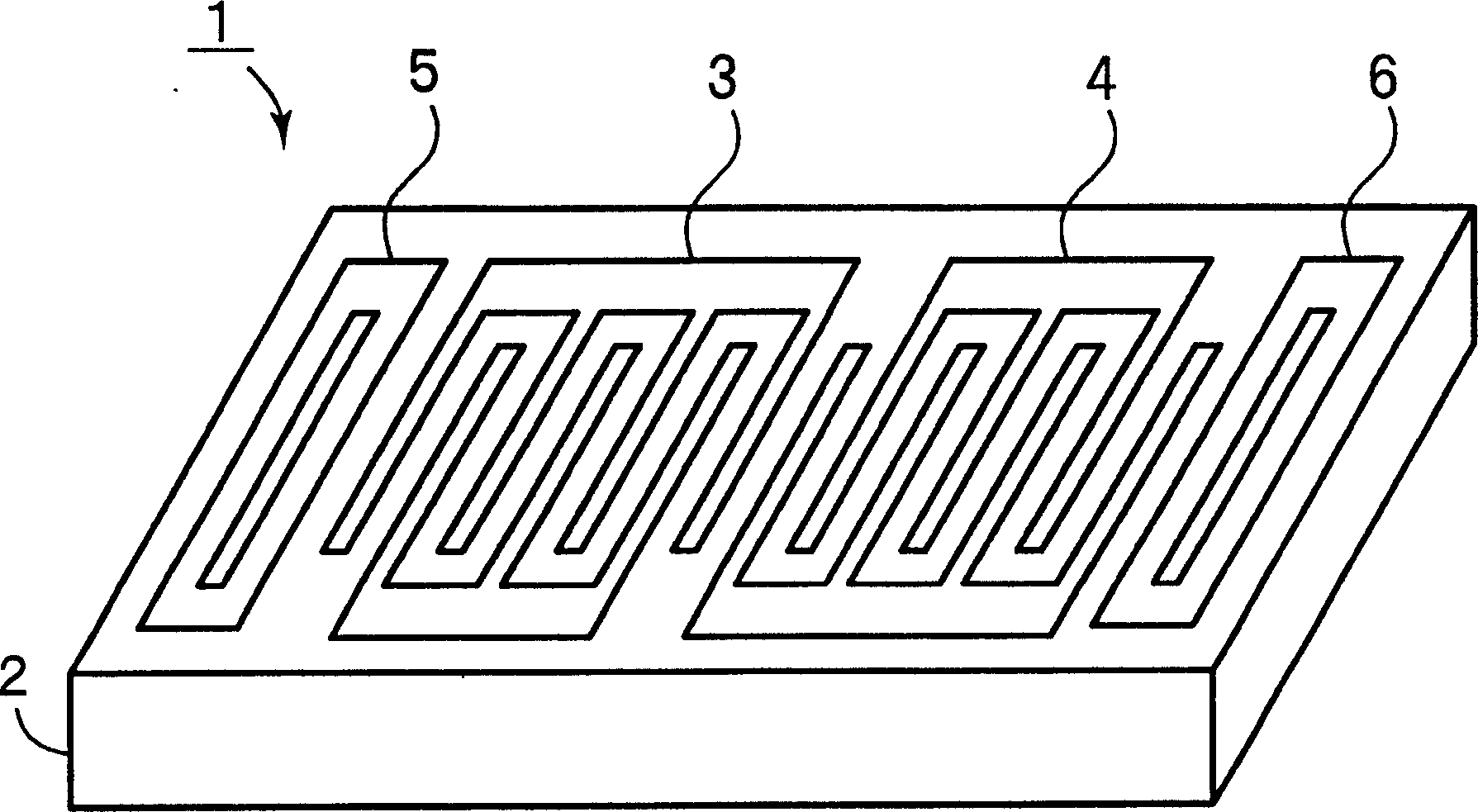

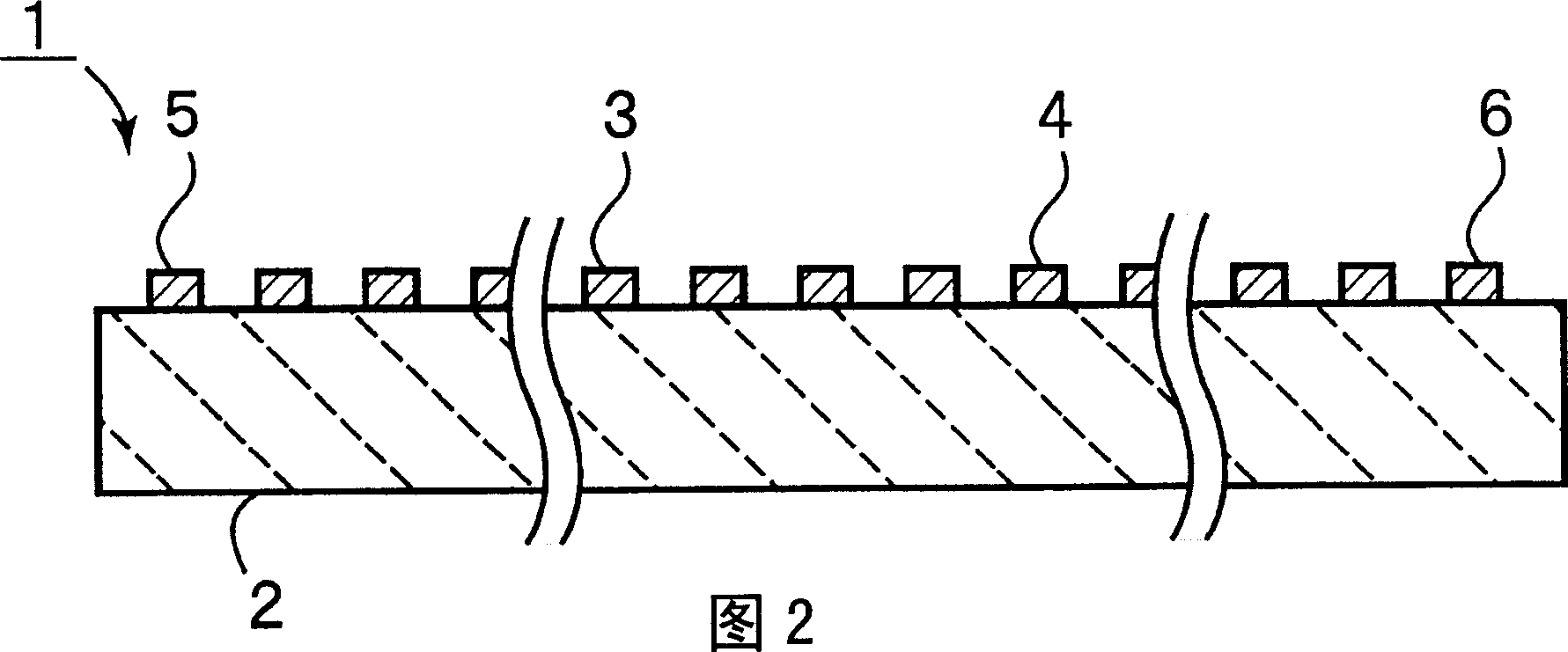

[0032] figure 1 It is a schematic perspective view of a surface acoustic wave device according to an embodiment of the present invention, and FIG. 2 is a schematic partial cutaway front sectional view.

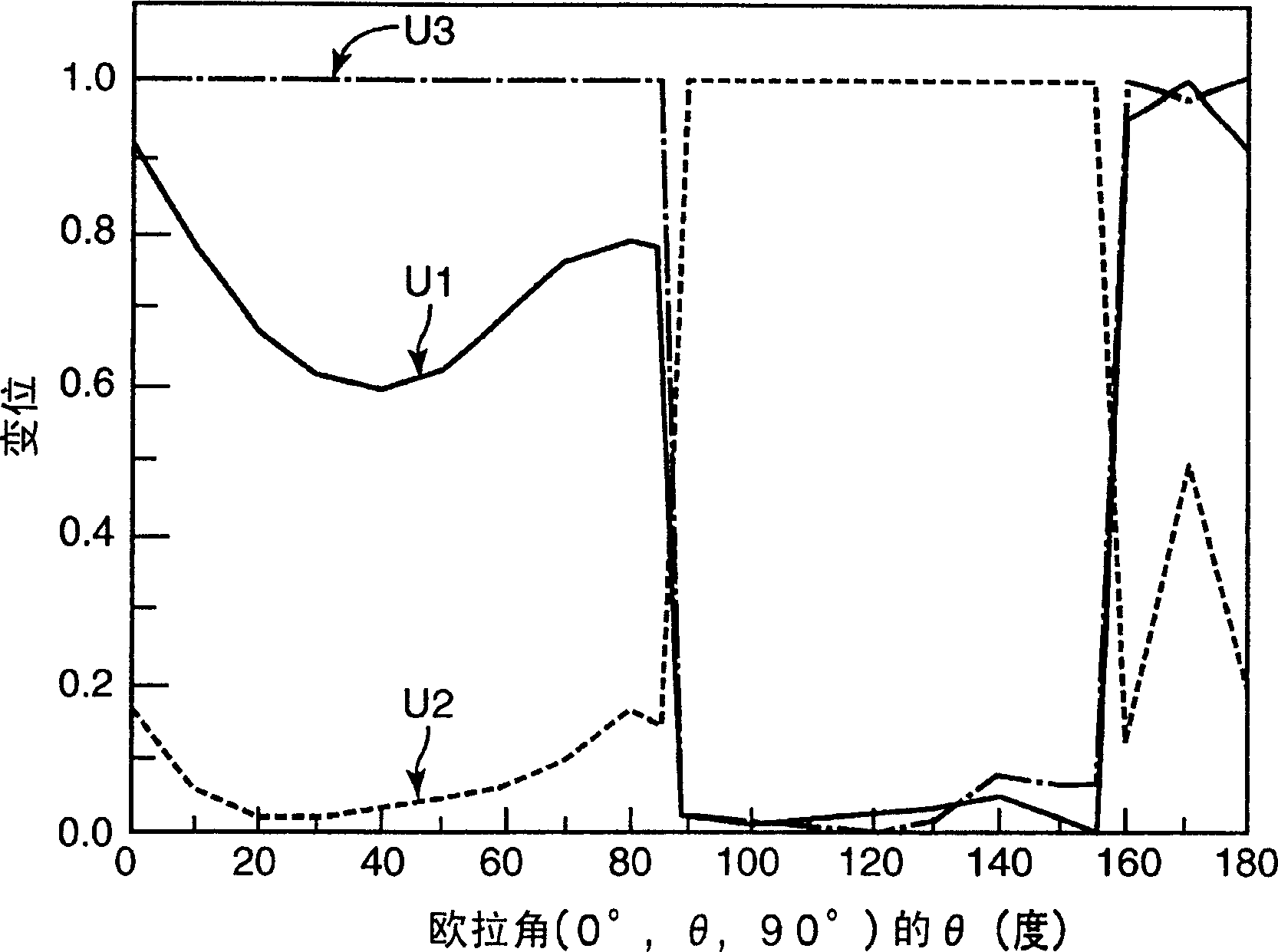

[0033] The surface acoustic wave device 1 has an ST-cut crystal substrate 2 . The crystal substrate 2 is a crystal substrate with an ST-cut 90° X conveyance and an Euler angle of (0°, 90°-150°, 90°±5°). IDTs (Interdigital Electrodes) 3 and 4 and reflectors 5 and 6 are formed on a crystal substrate 2 . The IDTs 3 and 4 and the reflectors 5 and 6 are made of aluminum, the film thickness H / λ normalized to the wavelength of the surface wave is in the range of 0.04 to 0.18, and the plating ratio of the electrode fingers is in the range of 0.53 to 0.87.

[0034] In the surface acoustic wave devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com