Working truck

A hydraulic shifting technology for working vehicles, which is applied to construction vehicles, gear transmissions, fluid transmissions, etc., can solve the problems of increased shifting operating force and poor output efficiency, so as to improve operating capabilities, improve low-speed driving performance, High effect of stepless speed change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

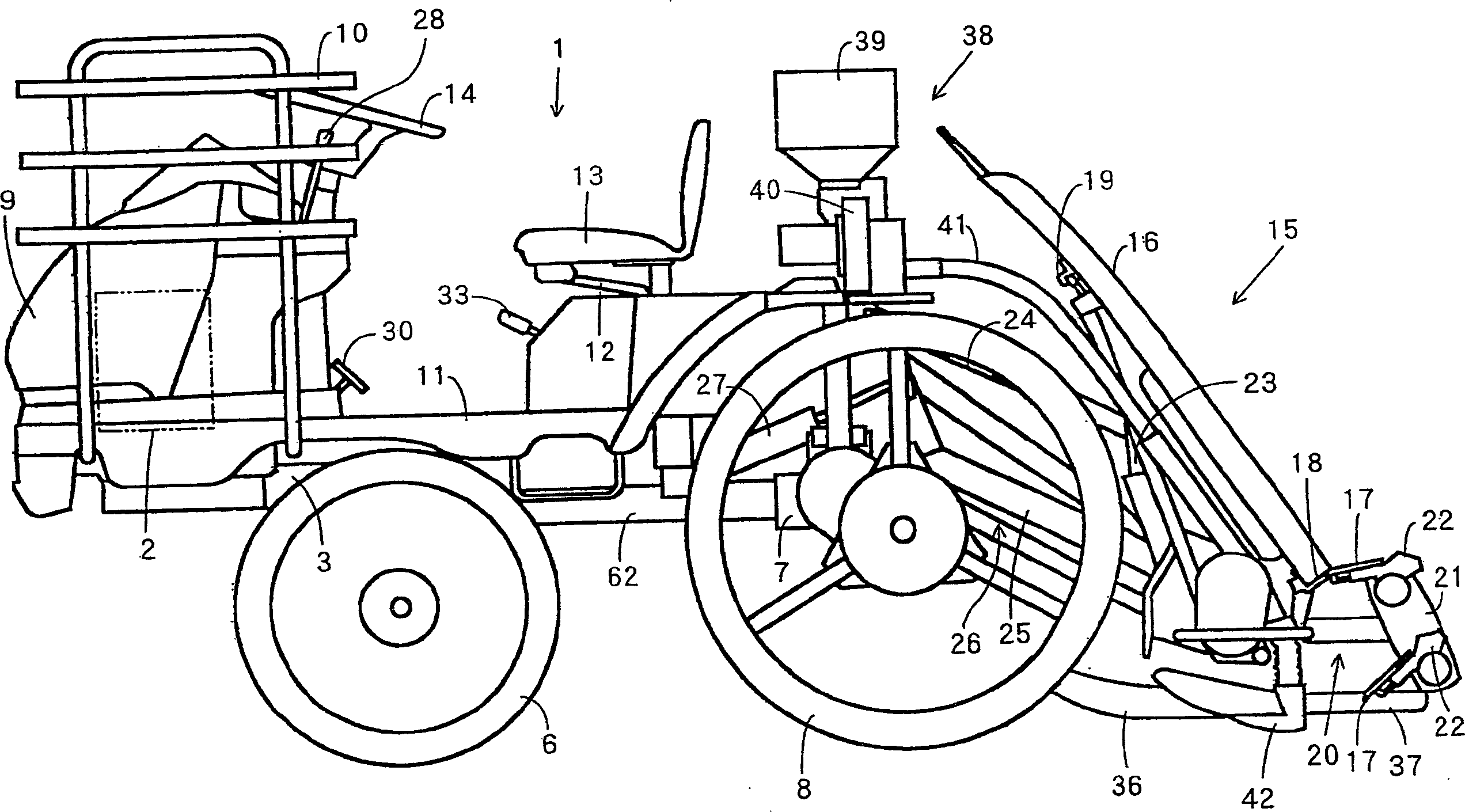

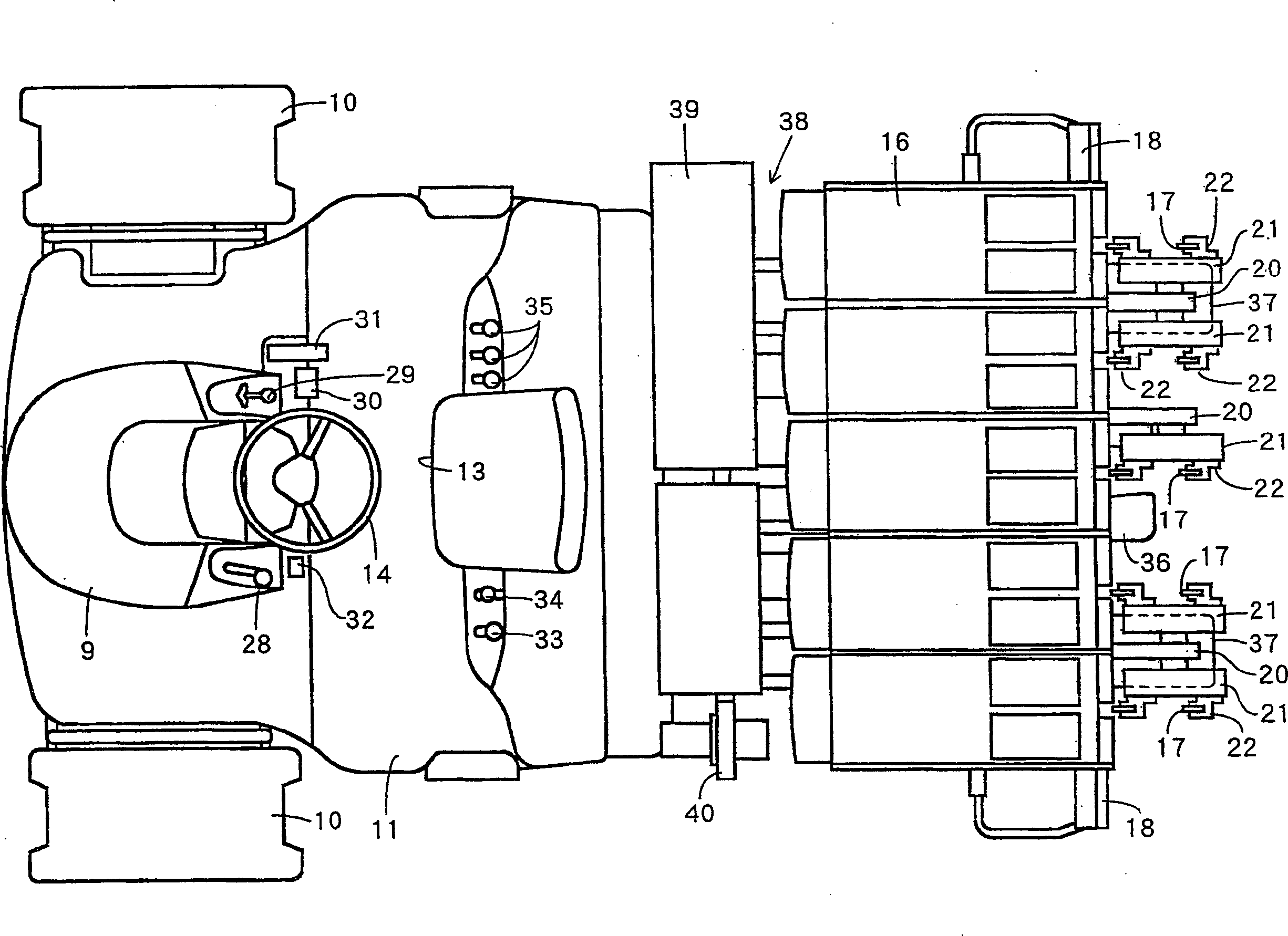

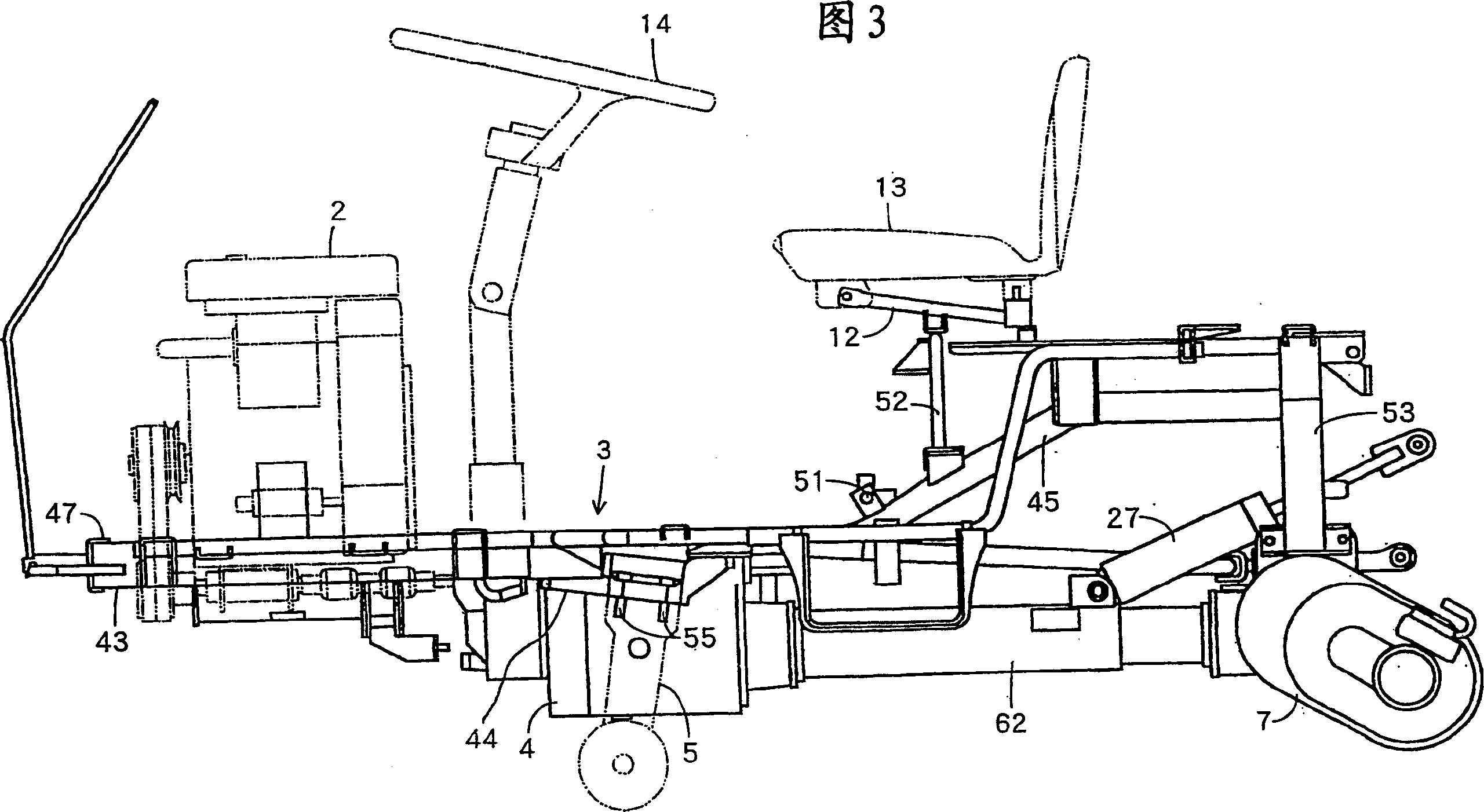

[0036] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings. figure 1 is the overall side view, figure 2 It is the same top view, and Fig. 3 is a side view of the vehicle body frame, and Fig. 4 shows the same top view, among which 1 is a traveling vehicle on which the operator takes, the engine 2 is mounted on the vehicle body frame 3, and the paddy fields travel with the front wheels 6 The front axle case 5 is supported on the side of the transmission case 4, and at the same time, the rear wheel 8 for paddy field driving is supported on the rear axle case 7 behind the above-mentioned transmission case 4. Like this, at the both sides of the hood 9 that covers above-mentioned engine 2 etc., install preparatory seedling-carrying platform 10, simultaneously, cover above-mentioned transmission box 4 etc. by the vehicle body cover 11 that operator rides on, driver's seat 13 is passed through seat frame. 12, installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com