Self-balance type pressurized double support and control device therefor

A control device and self-balancing technology, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve the problem of increasing maintenance costs and manufacturing costs, and can not meet the quality of bobbin yarn winding and its forming quality. , unsatisfactory braking effect and other problems, to achieve the effect of improving yarn winding quality, good concentricity and reliable braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

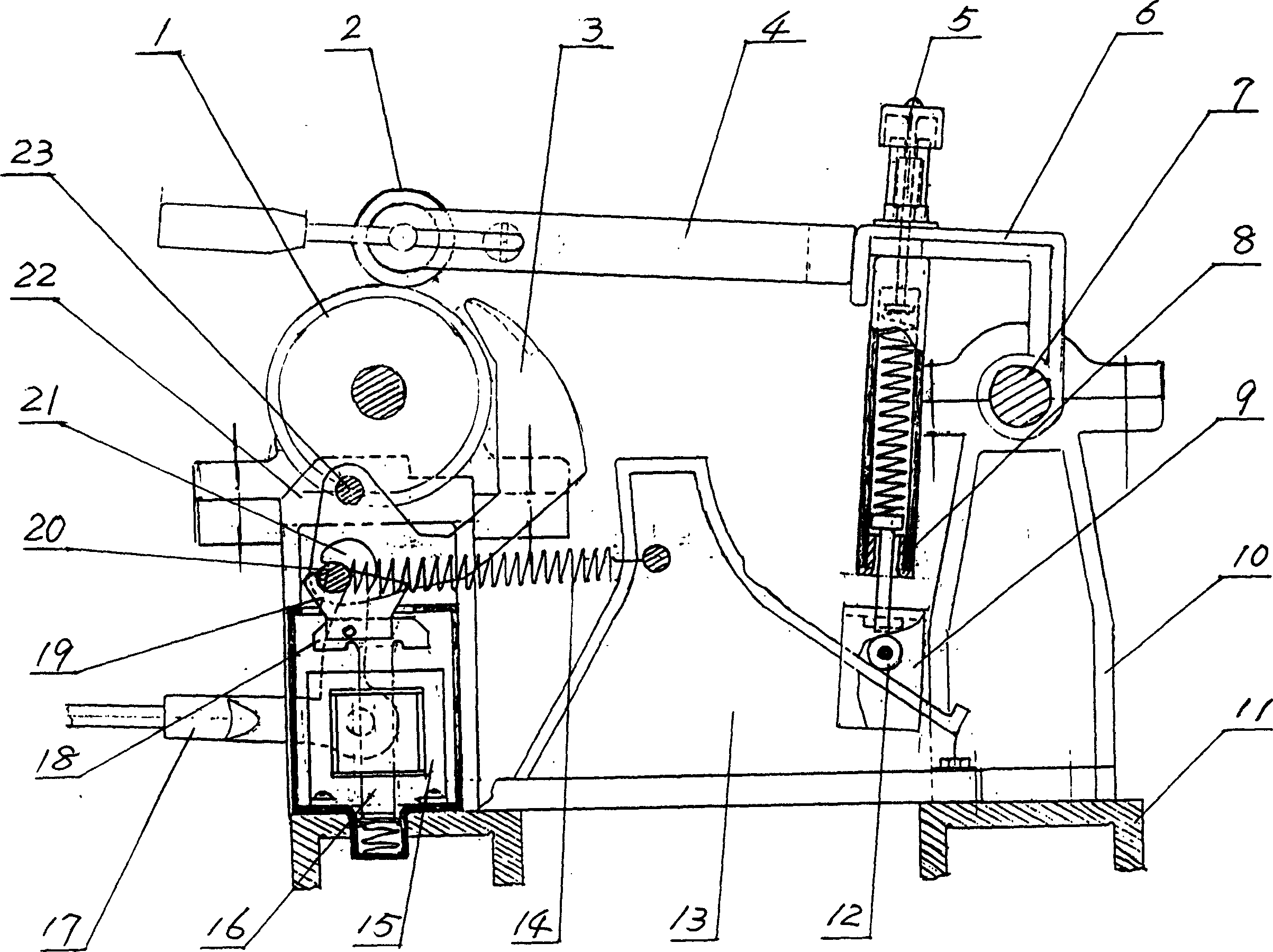

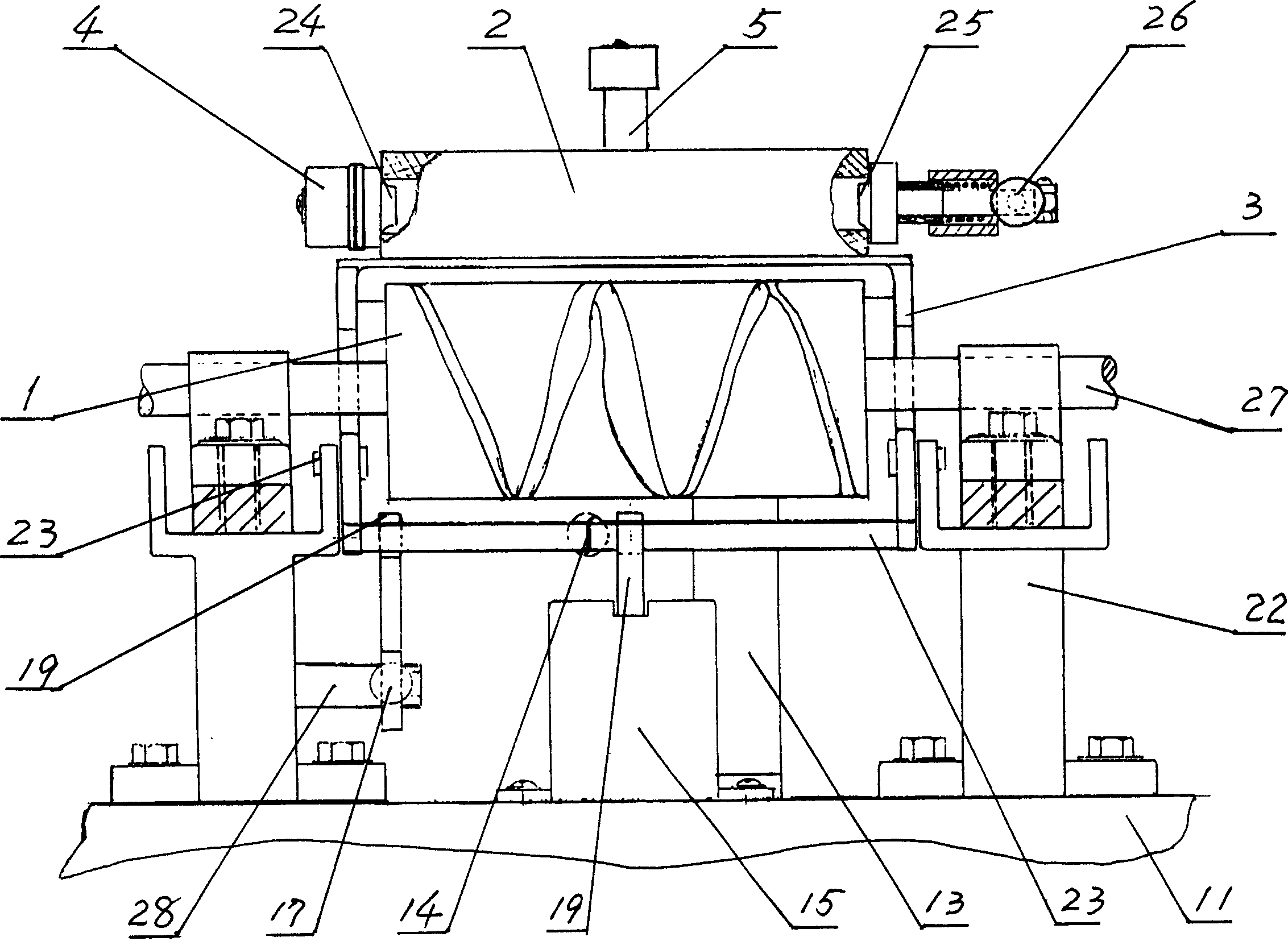

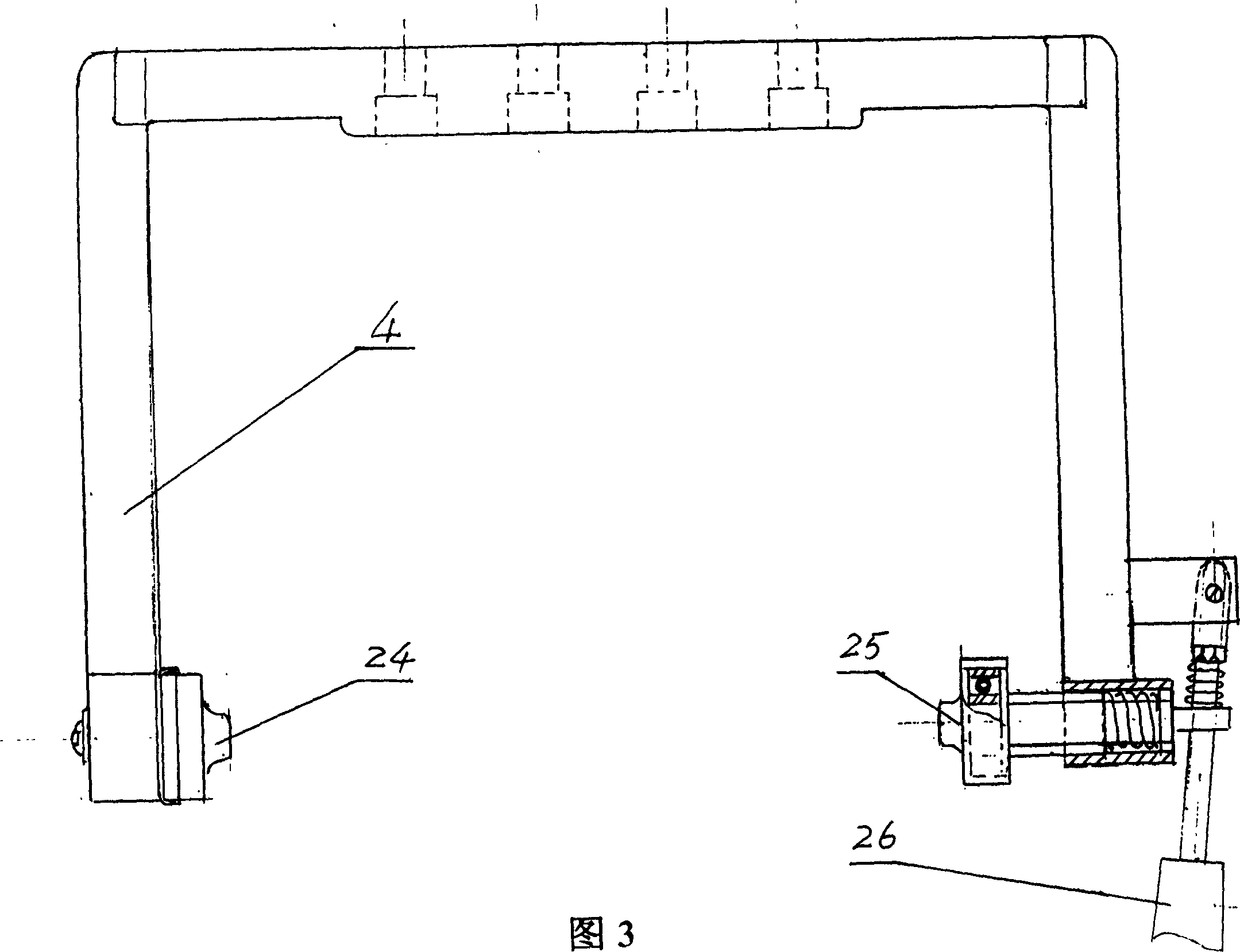

[0018] according to figure 1 -3 Describe the specific structure of the present invention in detail. The present invention is improved on the basis of the structure of the existing bobbin support control device of the yarn doubling machine, cancels the structure of the original split double support and its single-side cam presser, and redesigns the yarn signal detection control brake The structure of the electromagnet core rod, the hook of the locking tie rod, the reset handle, etc. The device includes a newly designed double support and its self-balancing presser, a direct-connected electromagnetic brake controlled by yarn signal detection and so on.

[0019] Wherein the double support is assembled on the support 10 of the frame 11 through the support shaft 7 . It is composed of an integral double support frame 4 and a connecting arm 6 made of lightweight materials, such as aluminum alloy materials, hard plastics, etc., and assembled into one body through fasteners. The lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com