Construction method of composite ground foundation

A construction method and technology of composite foundation, which can be applied in basic structure engineering, soil protection, construction, etc., can solve the problems of construction environment pollution, inability to further improve the bearing capacity of piles, inability to adjust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

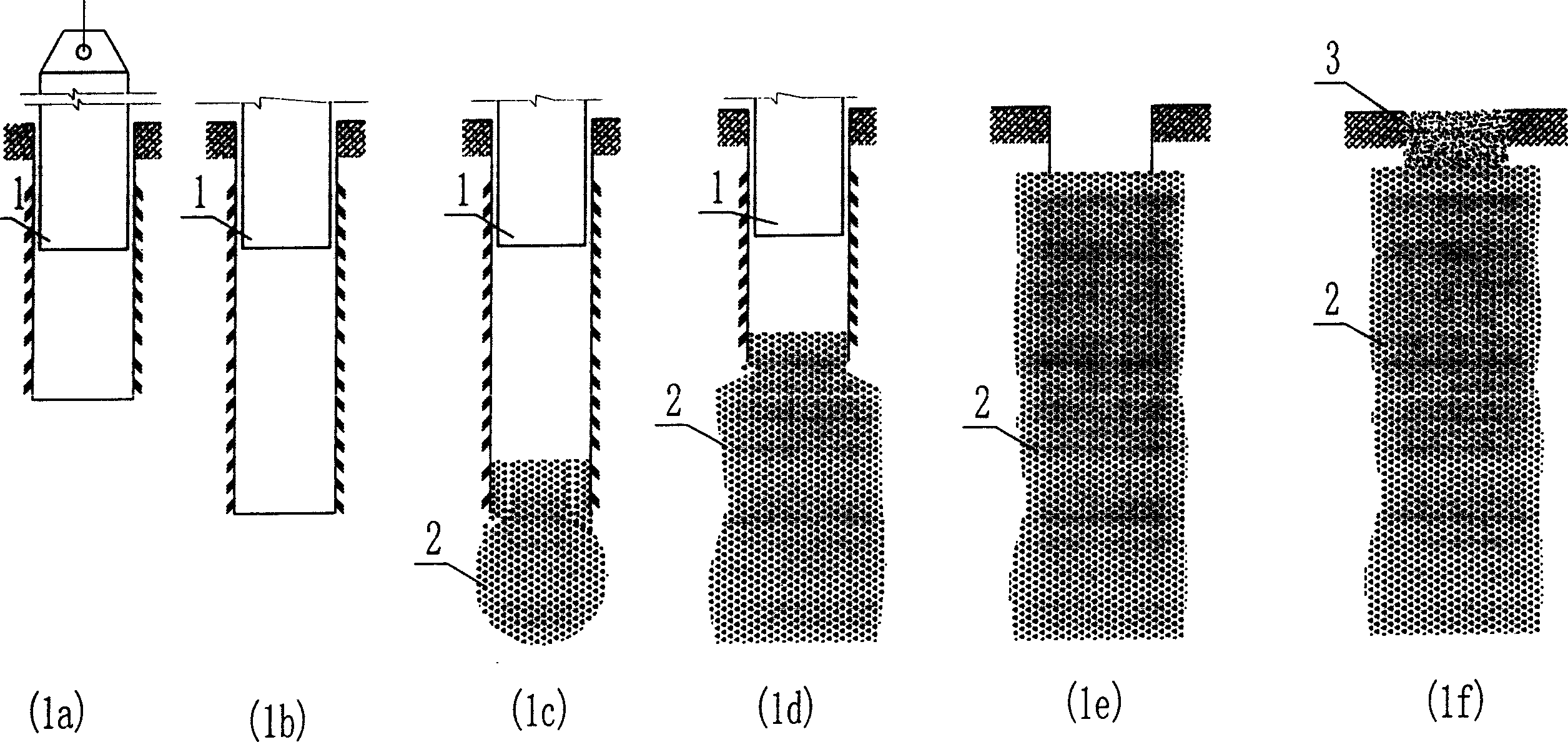

[0022] As an embodiment of the present invention, a method for constructing a composite foundation includes the following steps. First, as figure 1 As shown in a, the rammer 1 is used for free fall to perform punching and expansion to form a pile hole; then, as shown in figure 1 As shown in b, the above-mentioned rammer 1 is punched and expanded to a certain depth in the hole, and the depth of the hole should satisfy that when the hammer weight is constant and the drop distance is constant, the penetration degree of the rammer 1 is less than or equal to the design value, and it can be stopped. If the penetration of one blow is greater than the design value, it should continue to strike downward until the design value is met; then, if figure 1 As shown in c, fill the above-mentioned holes with reinforcing material 2, use the above-mentioned tamper 1 to ram the filled reinforcing material 2, and the penetration degree of the last blow should meet the above-mentioned design value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com