Press probe

A pressure, pressure sensor technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through mechanical components, furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

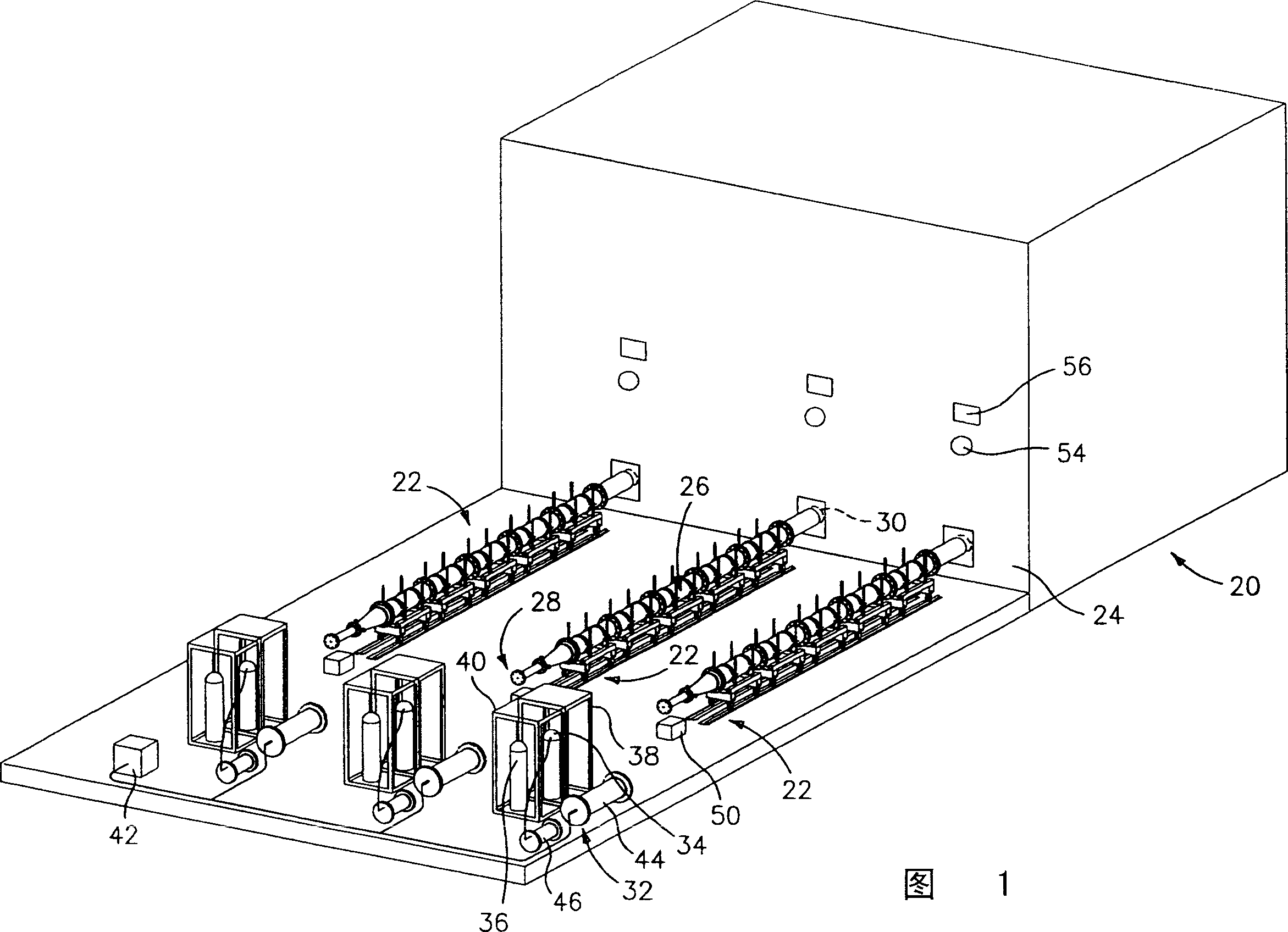

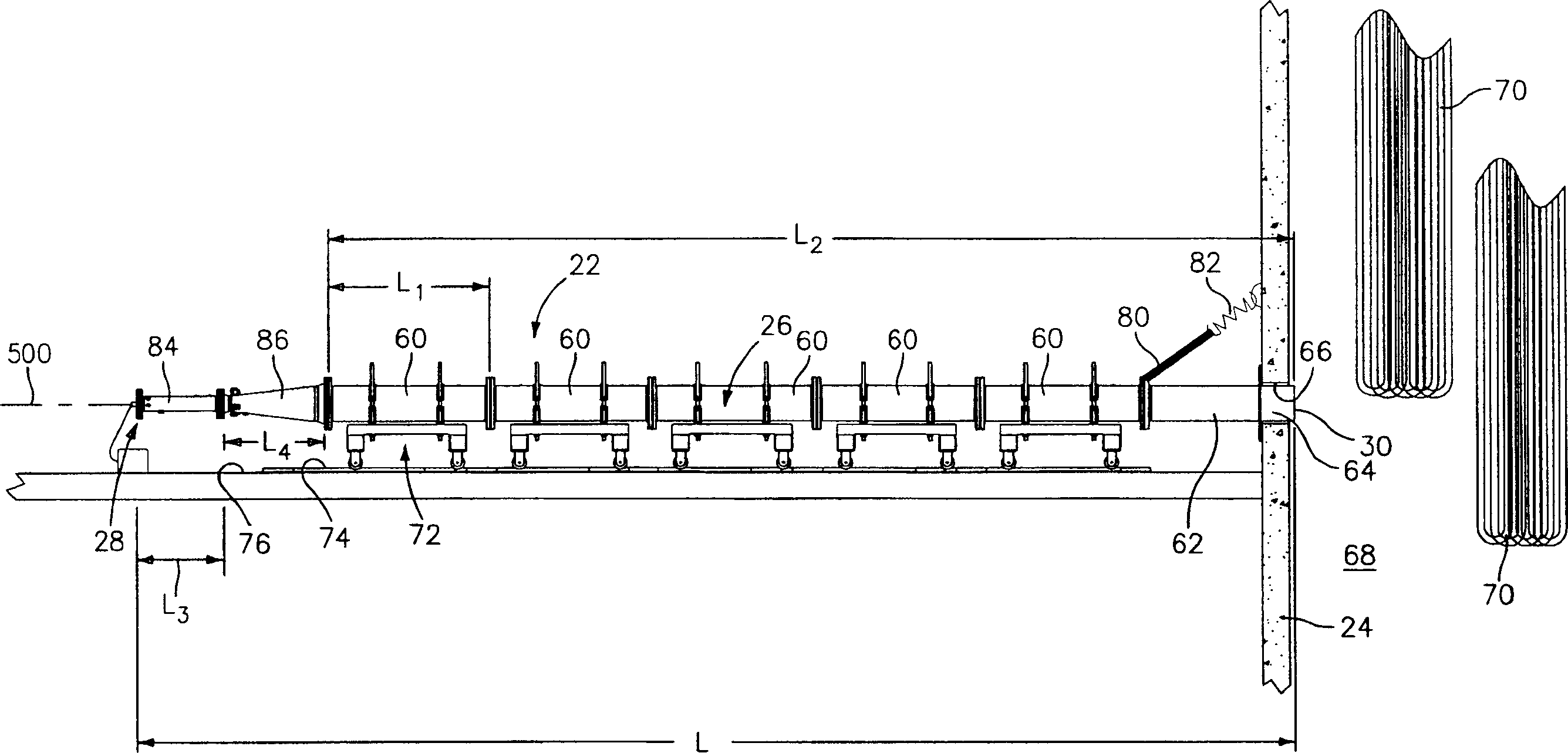

[0021] FIG. 1 shows a furnace 20 with exemplary three associated sootblowers 22 . In the embodiment shown, the shaft is formed in the form of a regular parallelepiped and the sootblowers are all associated with a single common wall 24 of the shaft and are arranged at the same height along the wall. Other configurations (eg, a single sootblower, one or more sootblowers on each of multiple levels, etc.) may also be used.

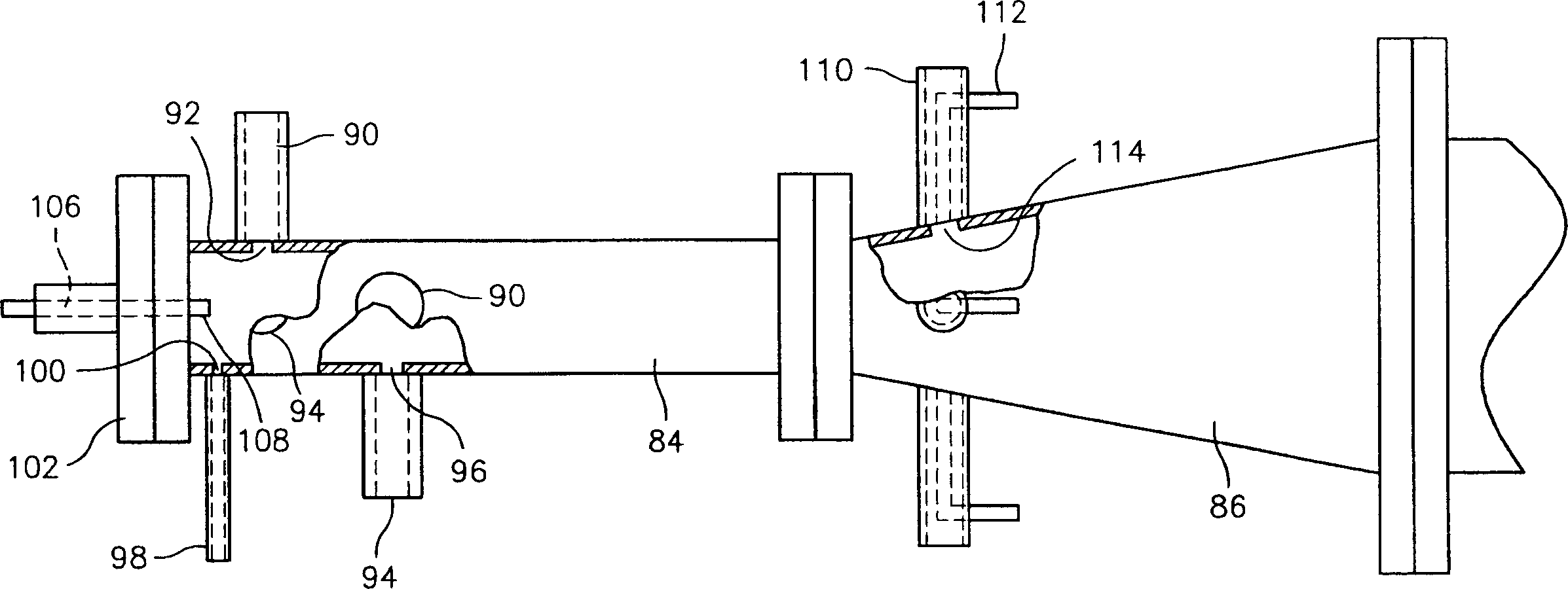

[0022] Each sootblower 22 includes an elongated combustion conduit 26 extending from an upstream distal end 28 remote from the furnace wall 24 to a downstream proximal end 30 proximate the wall 24 . Optionally, however, end 30 may be suitably located within the furnace. In operation of each sootblower, combustion of the fuel / oxidant mixture located within the conduit 26 begins near the upstream end (e.g., within the most upstream 10% of the conduit length) to generate a detonation wave which, along with the associated combustion gases It is emitted from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Maximum horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com