Asphalt modifier in use for aggregate modification of acidity of bituminous concrete and preparation method

An asphalt modifier and acid aggregate technology, applied in the field of asphalt modifiers, can solve the problems of poor durability and high temperature stability, and achieve the effects of good durability, reduced road maintenance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

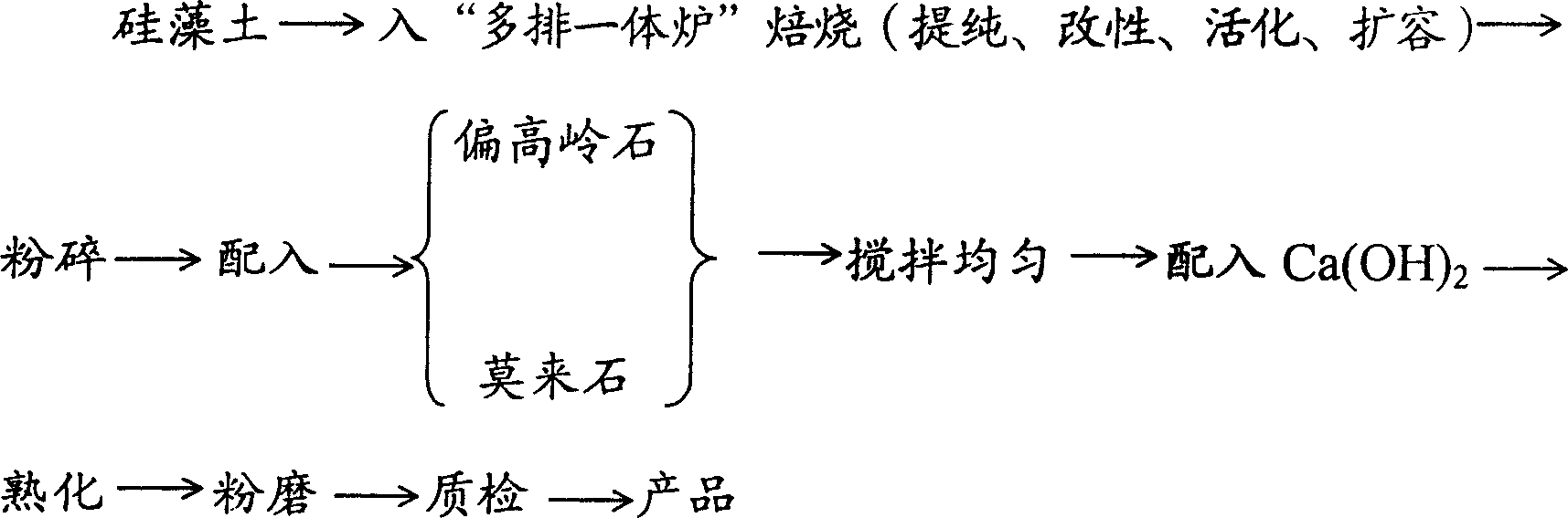

[0027] The main equipment actually used are: multi-row integrated furnace, hammer crusher, hurricane superfine self-grinding machine, maturing warehouse, batching machine, mixer, packaging machine.

[0028] There are 4 kinds of raw materials: 1. Diatomite; 2. Metakaolinite; 3. Mullite; 4. Ca(OH) 2 .

[0029] 1. Diatomite is purified, modified, activated and expanded through a "multi-row integrated furnace". The specific method is: break the block diatomaceous earth into flakes with a thickness of about 20cm, put it into a "multi-row integrated furnace", and then come out after drying, spontaneous combustion, heat preservation, and cooling. The whole process takes 9 hours. Dry for 2 hours, spontaneously ignite for 3 hours, keep warm for 2 hours, and cool down for 2 hours. The spontaneous combustion temperature is 600~800℃. After the diatomaceous earth is roasted in a "multi-row integrated furnace", it is beige. See Table 4 for various chemical components. Crush into powder by hamme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com