Multicomponent system for improving modulus of asphalt mixture, and application method and modified asphalt thereof

A technology of asphalt mixture and application method, which is applied in building insulation materials, building components, buildings, etc., and can solve problems such as unsatisfactory low-temperature flexibility and crack resistance of asphalt concrete, unguaranteed low-temperature flexibility, and restricted production conditions. , to achieve the effect of improving high temperature stability, ensuring high strength and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example provides a multi-component system for improving the modulus of asphalt mixture, which consists of 1 part of organic activated calcium sulfate whisker, 6 parts of waste tire rubber powder and 1 part of inferior animal and vegetable oil, wherein the organic activated calcium sulfate whisker is Calcium sulfate whiskers with borate-modified surfaces.

[0030] The method of applying this multi-component system to modified asphalt is as follows:

[0031] Put 0.5 parts of low-quality animal and vegetable oil in a cylindrical sealed tank, cover the surface with 6 parts of waste tire rubber powder, seal the sealed tank and place it in an oven at a temperature of 110°C for 2 hours; pour calcium sulfate whiskers Add 0.5 parts of low-quality animal and vegetable oil, and stir evenly; after the sealed tank is placed in the oven for 2 hours, take out and pour the mixture of low-quality animal and vegetable oil and waste tire rubber powder into hot asphalt at 130°C, keep ...

Embodiment 2

[0033] This example provides a multi-component system for improving the modulus of asphalt mixture, which consists of 2 parts of organic activated calcium sulfate whiskers, 7 parts of waste tire rubber powder and 2 parts of inferior animal and vegetable oils, wherein the organic activated calcium sulfate whiskers are Calcium sulfate whiskers surface-modified with stearic acid.

[0034] The method of applying this multi-component system to modified asphalt is as follows:

[0035] Put 1 part of low-quality animal and vegetable oil in a sealed tank, cover the surface with 7 parts of waste tire rubber powder, seal the sealed tank and place it in an oven at a temperature of 130°C for 3 hours; pour calcium sulfate whiskers into 1 After the sealed tank is placed in the oven for 3 hours, take out and pour the mixture of low-quality animal and vegetable oil and waste tire rubber powder into the base asphalt at 120°C, keep warm and continue stirring for 90 minutes; remove the heat prese...

Embodiment 3

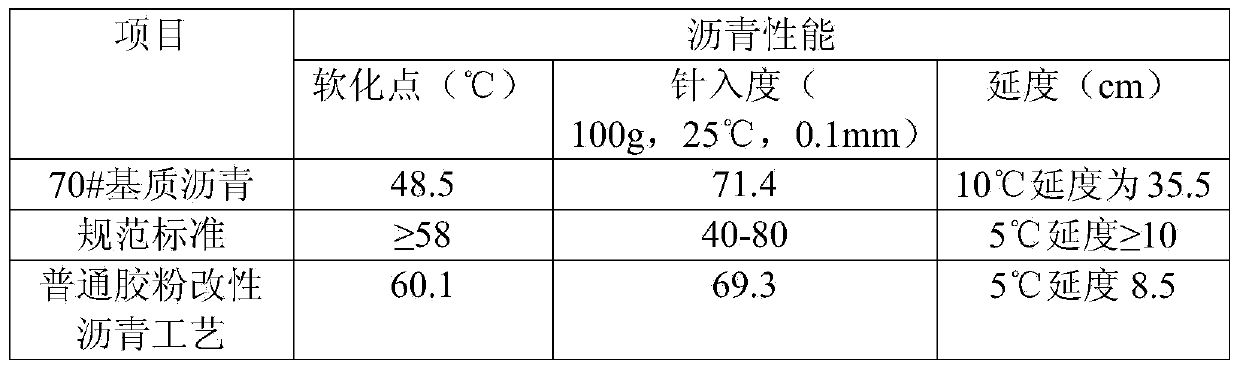

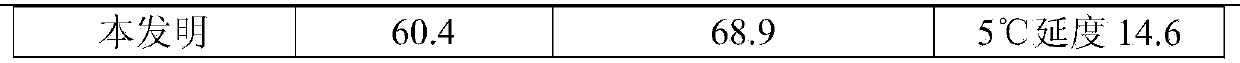

[0037] The modification effect of Example 1 of the present invention on 70# matrix asphalt was compared with that of ordinary rubber powder modified asphalt process. The results show that the present invention not only greatly improves the high-temperature stability of 70# matrix asphalt, but also significantly improves the low-temperature extension than ordinary rubber powder under the premise of fully meeting the national standard "Waste Tire Rubber Powder Rubber Modified Asphalt in Highway Engineering" JT / T798-2011 Modified asphalt process. At the same time, the test results also show that the multi-component system has good compatibility with asphalt. The specific experimental parameters are shown in Table 1.

[0038] Table 1 The present invention and ordinary rubber powder modified asphalt process test results

[0039]

[0040]

[0041] Note: The normative standards quoted in Table 1 are the requirements of climate zone-temperature zone

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com