Method for preparing asphalt modifier for various temperature conditions by using waste rubber oil and method for preparing modified asphalt

A technology of asphalt modifier and temperature conditions, which is applied in recycling technology, building components, building insulation materials, etc., can solve problems such as asphalt difficulty, achieve the effects of improving performance, improving high temperature stability, and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with the help of examples. However, the scope of protection claimed by the present invention is not limited to the scope expressed in the examples.

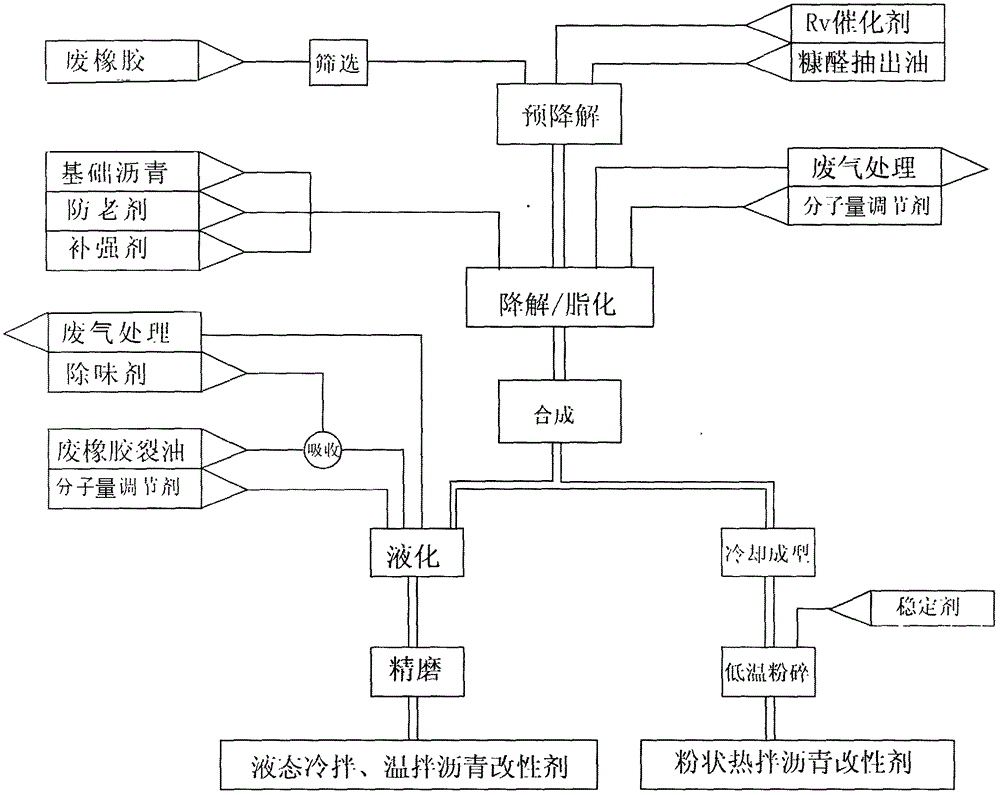

[0021] A kind of method utilizing waste rubber oil to prepare asphalt modifier under various temperature conditions, the technical solution adopted is to include the following production steps,

[0022] Step 1, based on the weight of waste rubber powder, 40-65 parts by weight of waste rubber powder is screened and sent to the pre-degradation kettle, and then 1-2 parts by weight of RV catalyst and 15-20 parts by weight of furfural oil are added, and the mixture is evenly stirred. At 70-14°C, after 20-45min pre-degradation;

[0023] Step 2: In terms of waste rubber powder weight parts, 10-15 parts by weight of base asphalt, 1-3 parts by weight of anti-aging agent, 5-20 parts by weight of molecular weight modifier and the pre-degraded material prepared in step 1 are put i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com