Bank protecting wall

A protective wall and prestressing technology, which is applied in the direction of coastline protection, etc., can solve the problems of inconvenient pouring of embankment protective walls, mechanical properties that cannot meet actual needs, and expensive construction of embankment protective walls. The effect of construction period, humanized design and simple and reasonable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

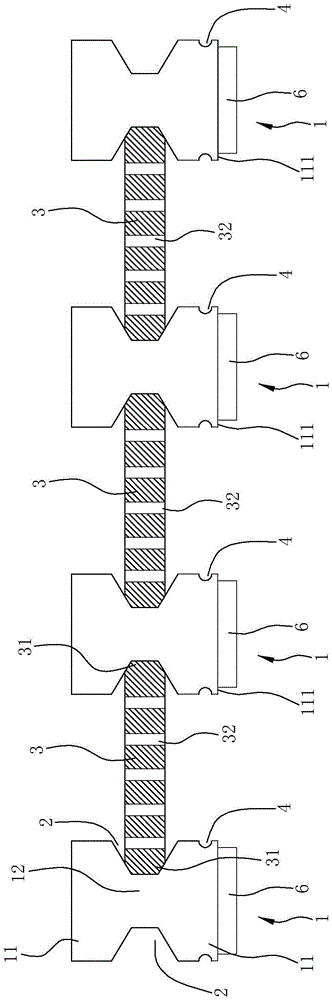

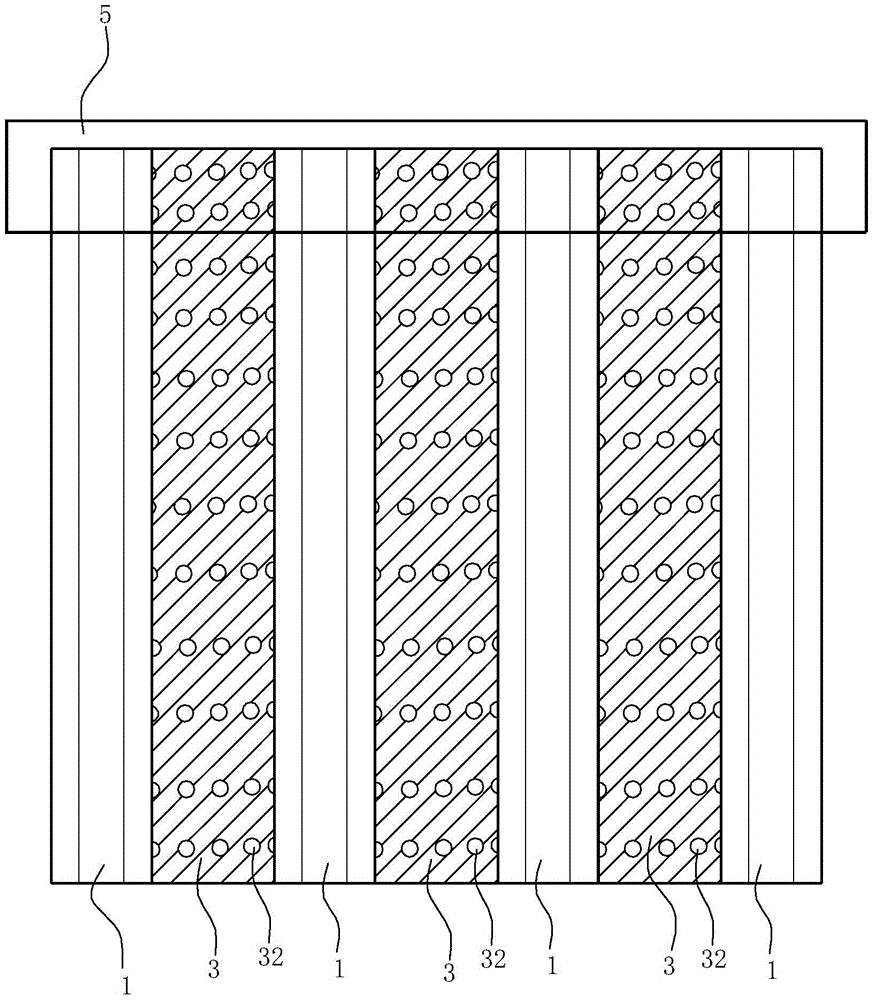

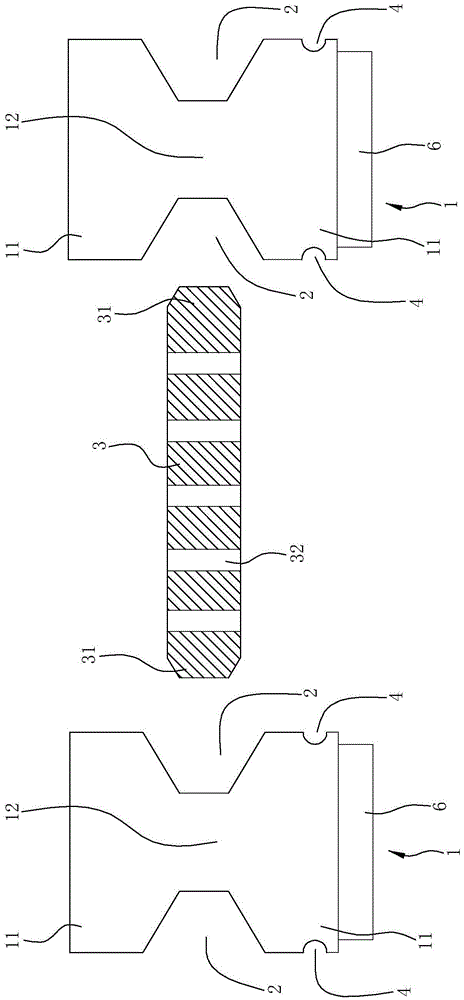

[0030] Such as Figure 1~4 Shown is the first embodiment of the present invention.

[0031] A bank embankment protection wall, including a plurality of H-shaped prestressed concrete piles 1 inserted into the soil of the embankment at intervals. The H-shaped prestressed concrete piles 1 are reinforced concrete structures with a length of 8 meters to 15 meters and are produced in a factory In the production process, prestress is applied to the steel bars in the pile body.

[0032] The cross section of the H-type prestressed concrete pile 1 is H-shaped formed by two flanges 11 and the web 12 connecting the two flanges 11. The grooves 2 extending along the length direction of the pile body are formed on both sides of the pile body, and a prefabricated insert 3 is arranged between two adjacent H-shaped prestressed concrete piles 1. 2, the insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com