Composite pressure pipe

A composite pipe, pressure-resistant technology, applied in the direction of hoses, pipes, rigid pipes, etc., can solve the problems of complicated manufacturing process, and achieve the effect of improving pressure resistance performance, realizing manufacturing process, and high pressure resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

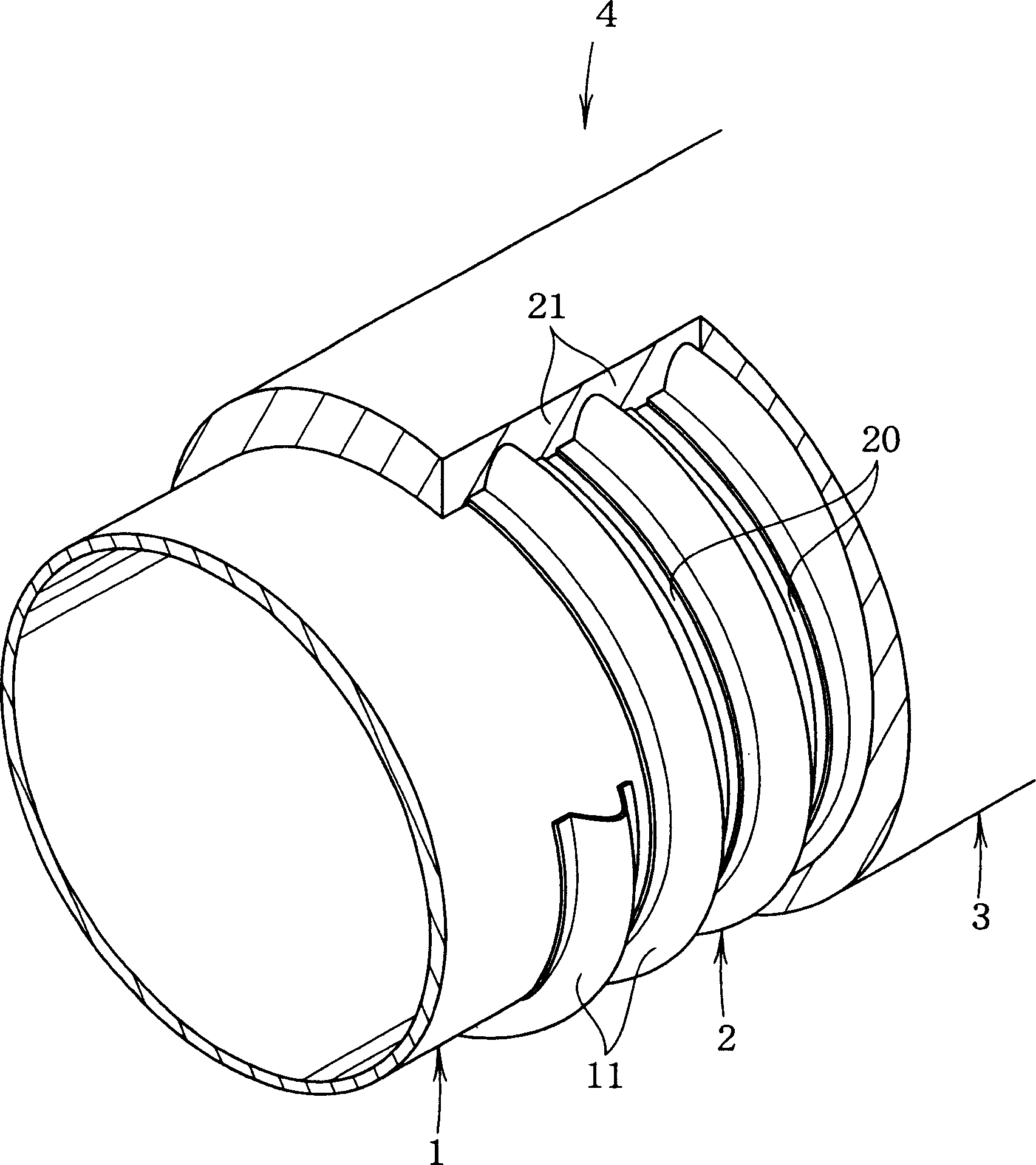

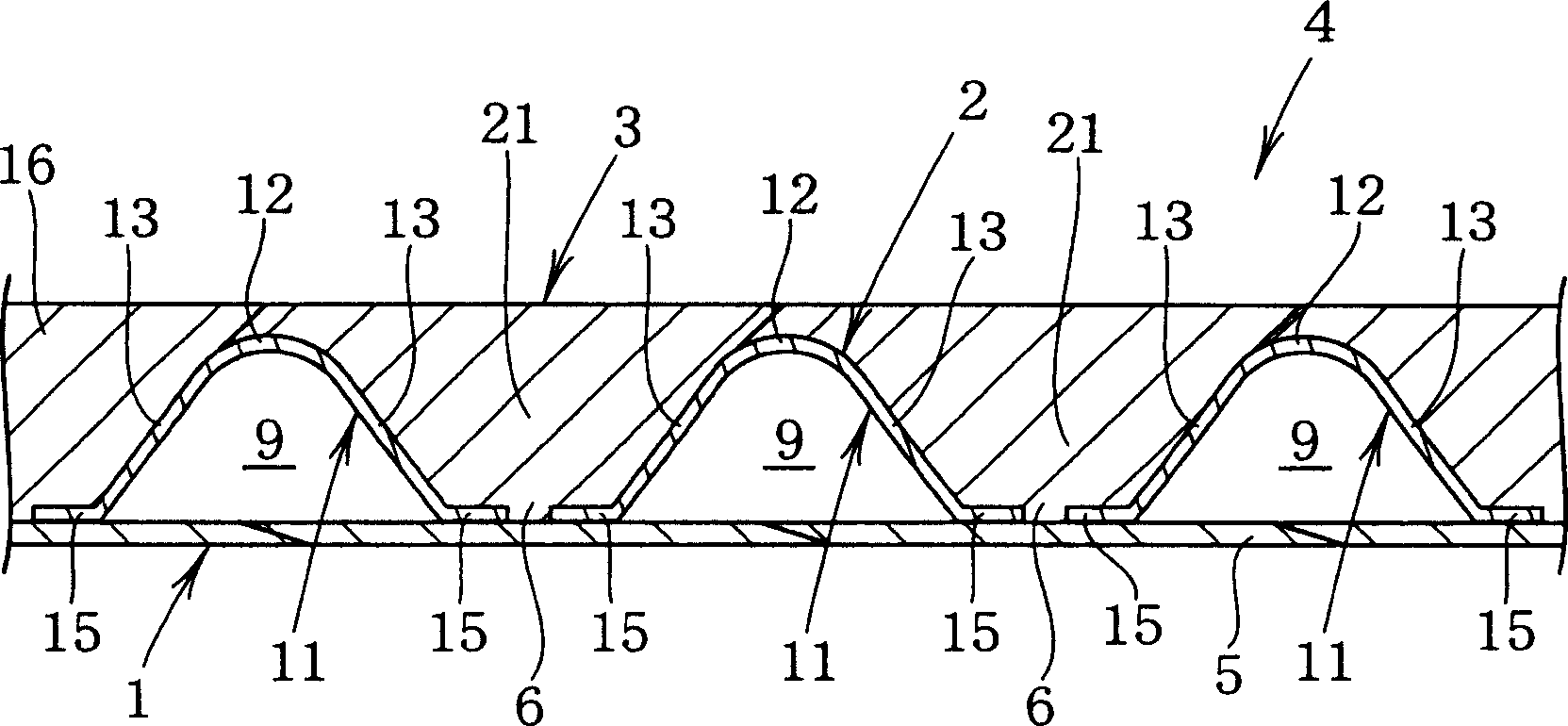

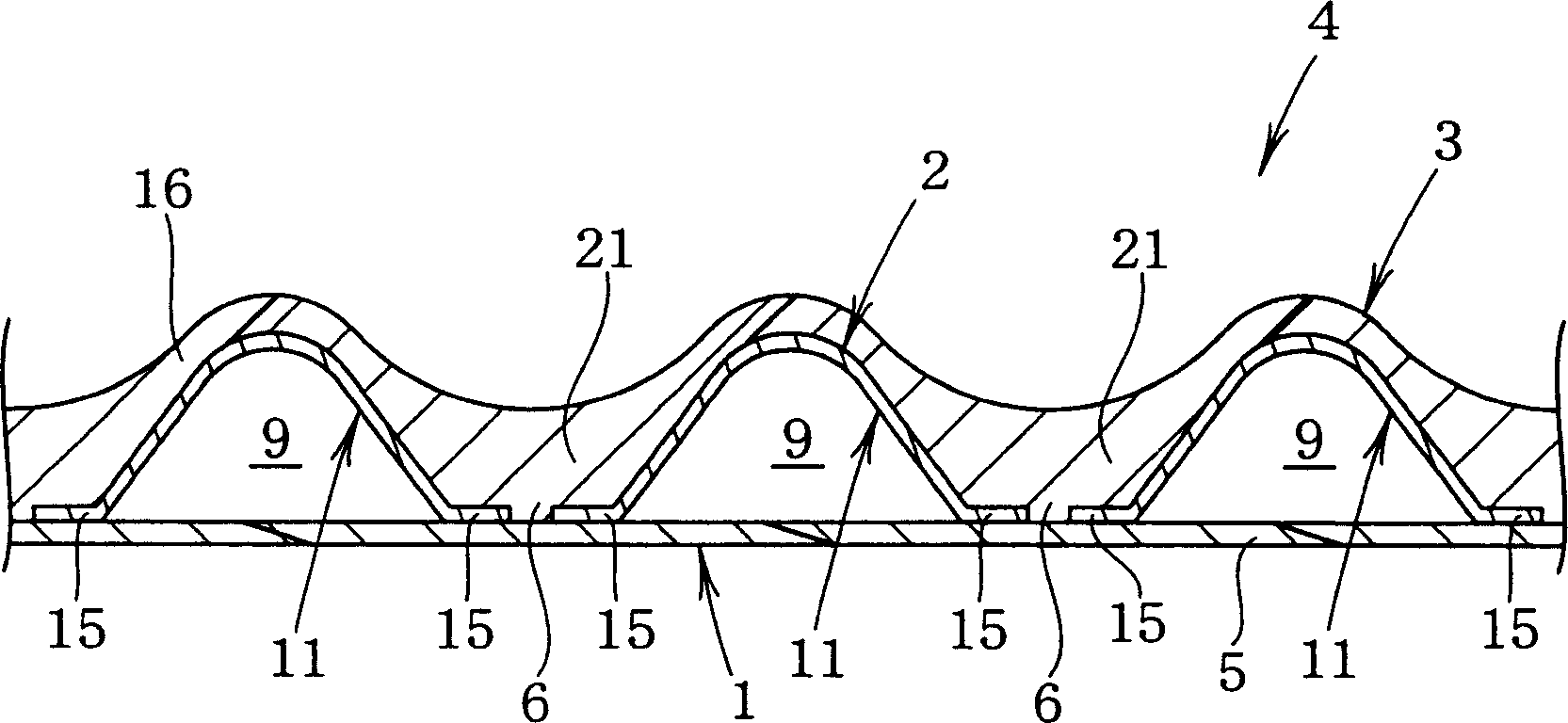

[0028] Embodiments of the present invention will be described in detail below based on the drawings. The pressure-resistant composite pipe according to Embodiment 1 of the present invention is used, for example, as a drainage pipe buried underground.

[0029] like figure 1 and 2 As shown, this pressure-resistant composite pipe includes an inner layer 1 made of synthetic resin, a metal belt-shaped reinforcement plate 2 provided along the outer peripheral surface of the inner layer 1, and a belt-shaped reinforcement plate 2 that covers the belt-shaped reinforcement plate 2. The pipe wall 4 is formed by the outer layer 3 made of synthetic resin on the outer peripheral surface.

[0030] The inner layer 1 can be constituted by, for example, helically winding a synthetic resin band 5 made of polyethylene resin, and thermally welding adjacent side edges along the tube axis direction. . However, instead of heat welding, the side edge portions may be joined to each other by adhesio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com