Mixed type helical groove dynamical and static pressure gas composite thrust bearing

A thrust bearing, dynamic and static pressure technology, applied in the direction of rotating bearings, sliding contact bearings, bearings, etc., can solve the problems of low bearing capacity, poor anti-interference ability, and small rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

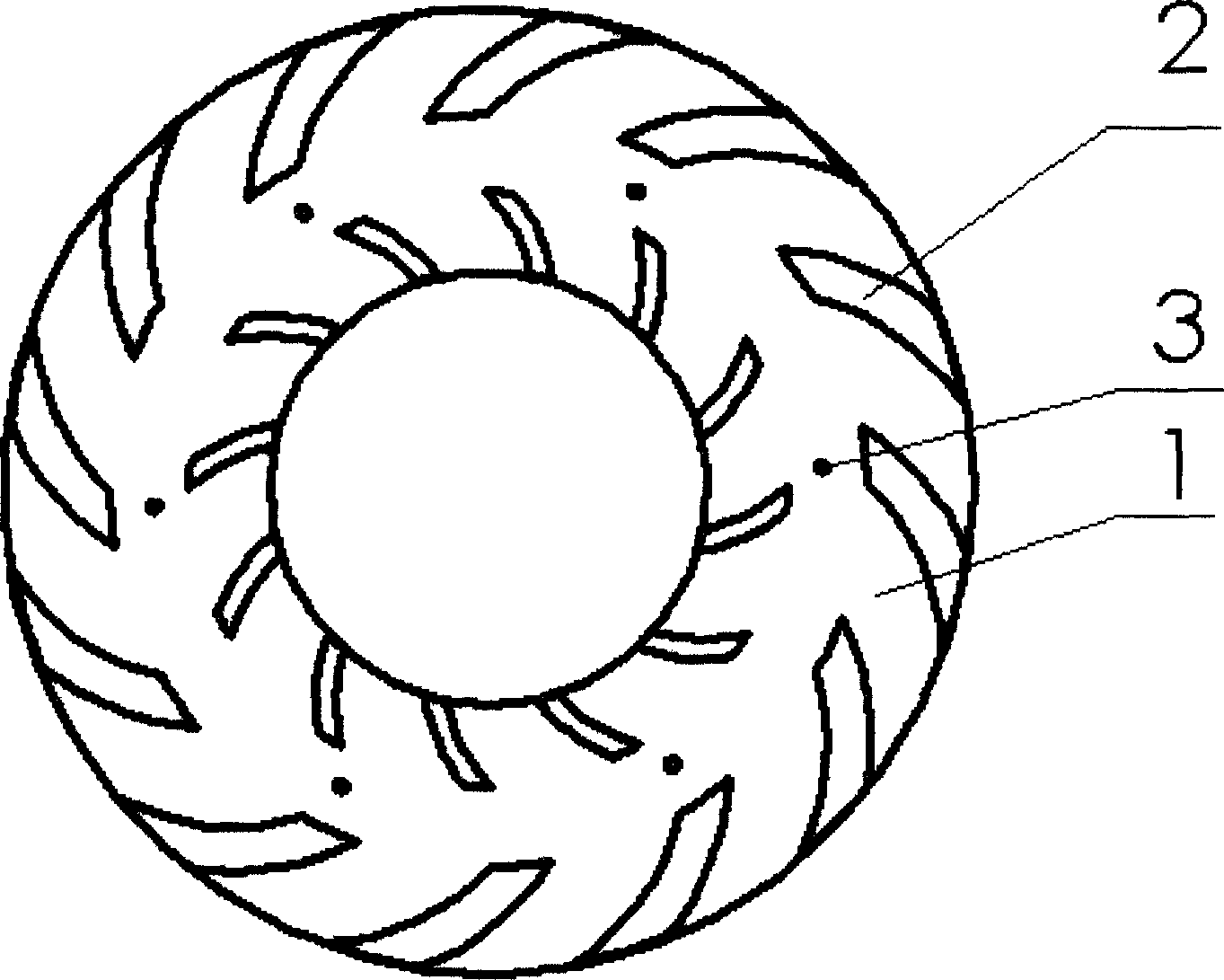

[0042] as attached figure 1 As shown, on the working surface 1 of the thrust bearing, there are respectively unconnected spiral dynamic pressure grooves 2 on both sides of the distribution circle of the static pressure air flotation air supply point 3, and the working surface is equipped with a smooth circular plane.

Embodiment 2

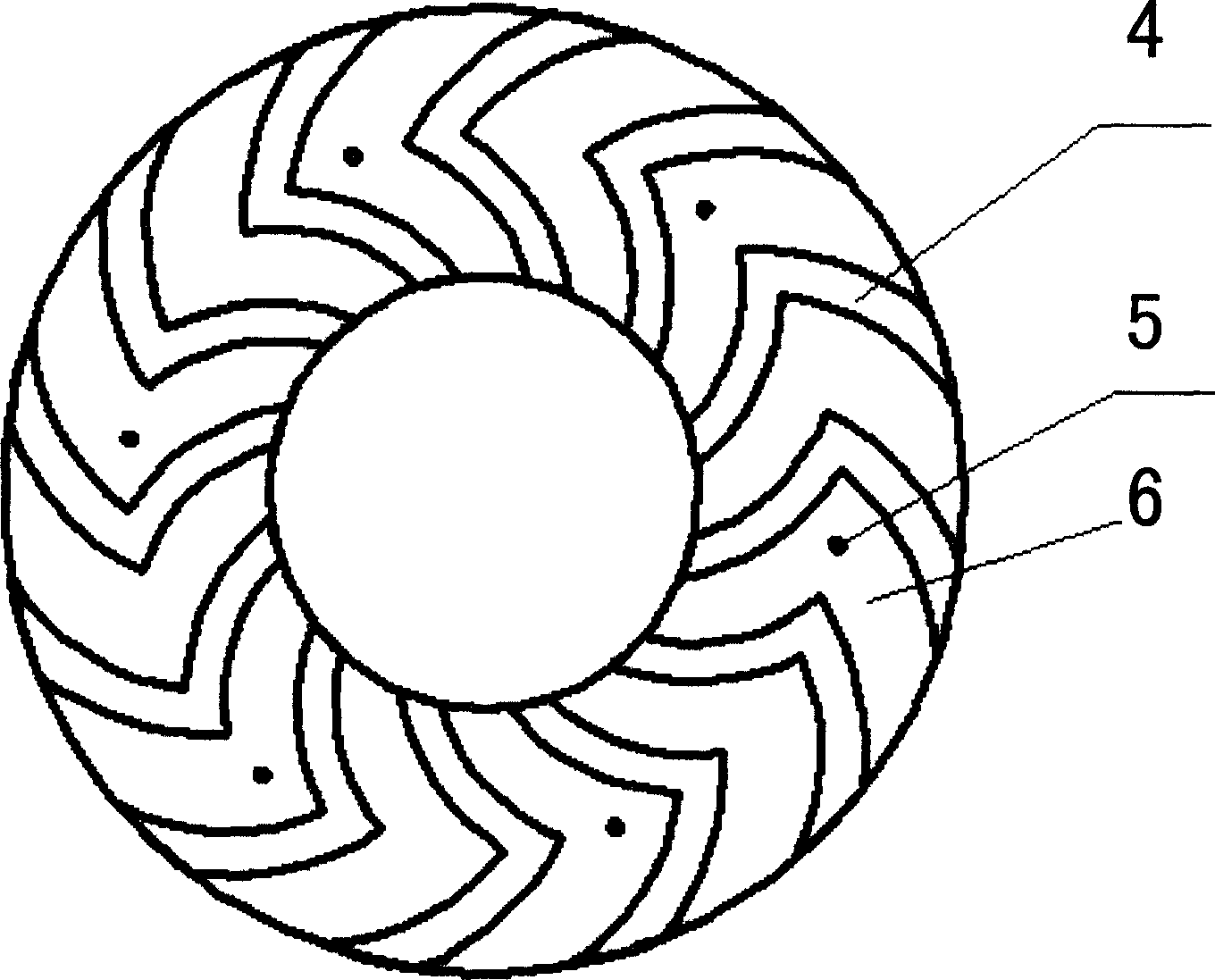

[0044] as attached figure 2 As shown, there are connected spiral dynamic pressure grooves 4 on both sides of the distribution circle of the static pressure air flotation air supply point 5 on the thrust bearing working surface 6, and the working surface is equipped with a smooth circular plane.

Embodiment 3

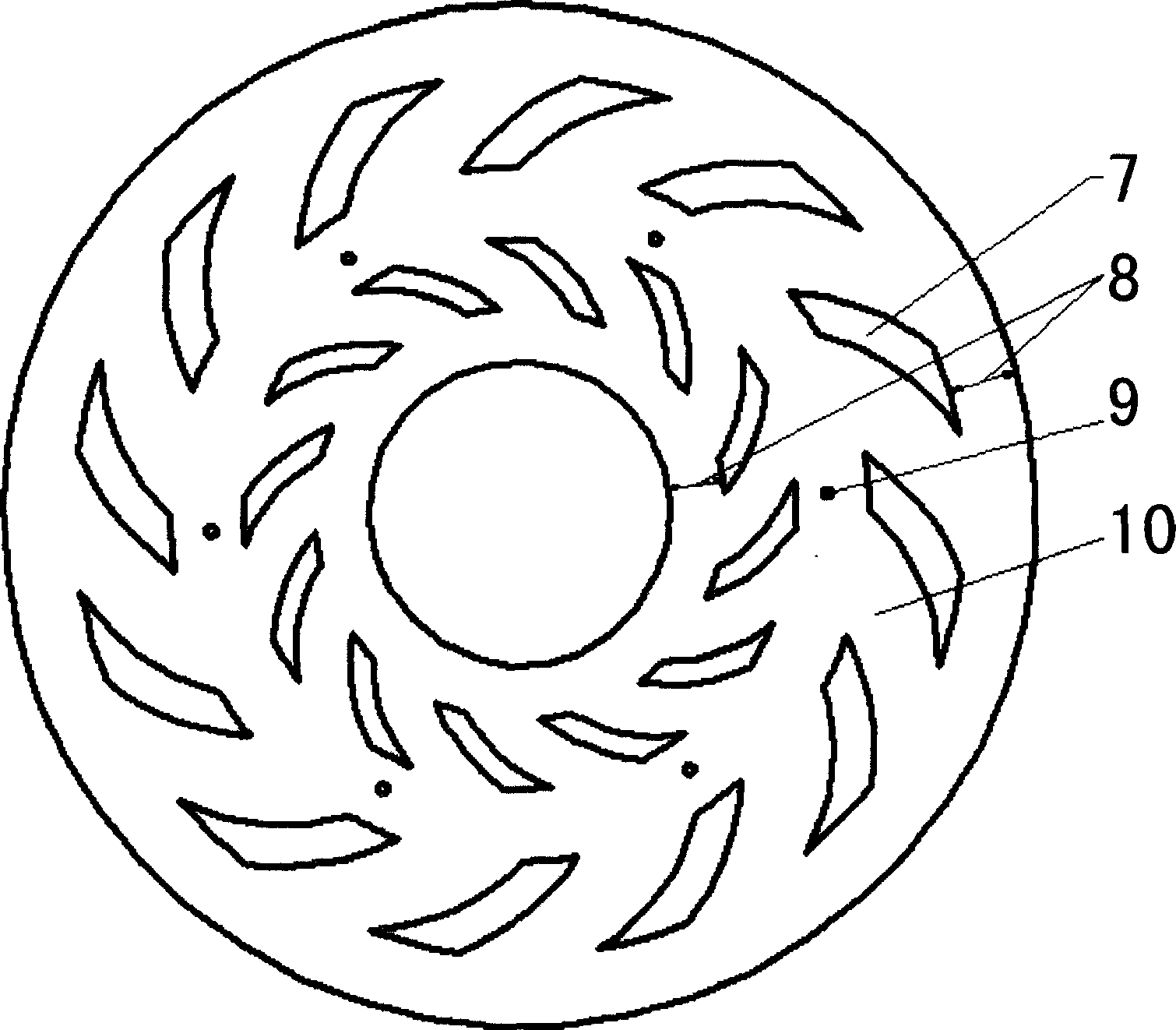

[0046] as attached image 3 As shown, on the working face 10 of the thrust bearing, there are disjoint spiral dynamic pressure grooves 7 on both sides of the distribution circle of the static pressure air flotation air supply point 9, and the outer sides of the spiral dynamic pressure groove 7 have air sealing edges. 8. The working surface is equipped with a smooth circular plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com