Laser divergence angle measuring instrument and measuring method

A measurement method and laser technology, applied in the direction of testing optical performance, etc., can solve the problems of narrow measurement range and low accuracy, and achieve the effect of improving test accuracy and small detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

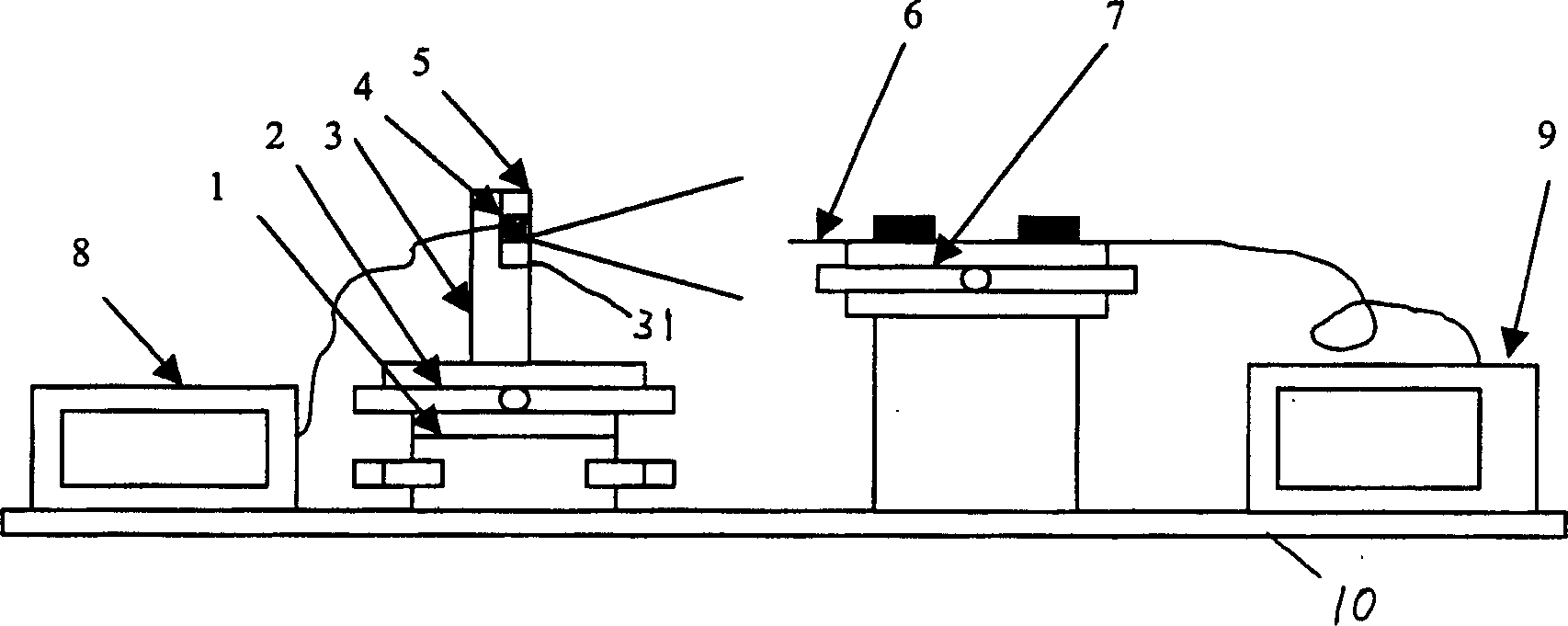

[0038] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown, a kind of laser divergence angle measuring instrument of the present invention comprises:

[0039] A rotary fine-tuning frame 1, the rotary fine-tuning frame 1 can be rotated and fine-tuned, and the rotary fine-tuning frame 1 is installed on the base 10 ( figure 1 middle);

[0040] A two-dimensional fine-tuning frame 2 is fixed on the rotating fine-tuning frame 1, and the two-dimensional fine-tuning frame 2 can be fine-tuned in the X and Y axis directions;

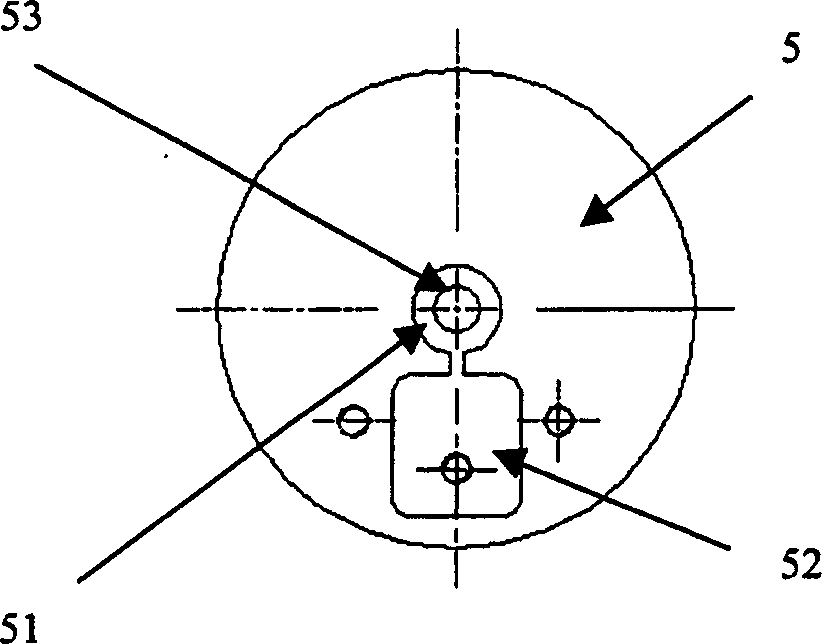

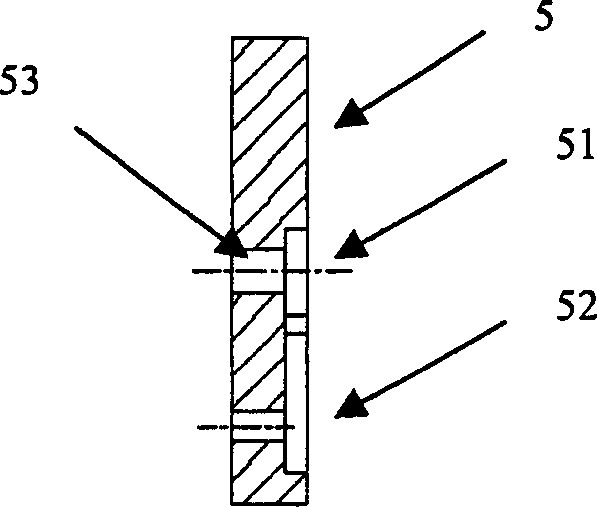

[0041] A cylindrical fitting 3, which is fixed on the two-dimensional fine-tuning frame 2, and has a circular groove 31 ( Figure 4 , Figure 5 middle); wherein in the circular groove 31 of the cylindrical fitting 3, a circular clamp 5 is inserted and fitted, and a circular groove 51 is arranged in the middle of the circular clamp 5 ( figure 2 , image 3 Middle), there is a square groove 52 below the circular groove 51, the square groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com