A liquid crystal dish structure

A liquid crystal and liquid crystal material technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of too many liquid crystal materials and waste of liquid crystal material production costs, and achieve the effect of reducing usage, improving injection efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

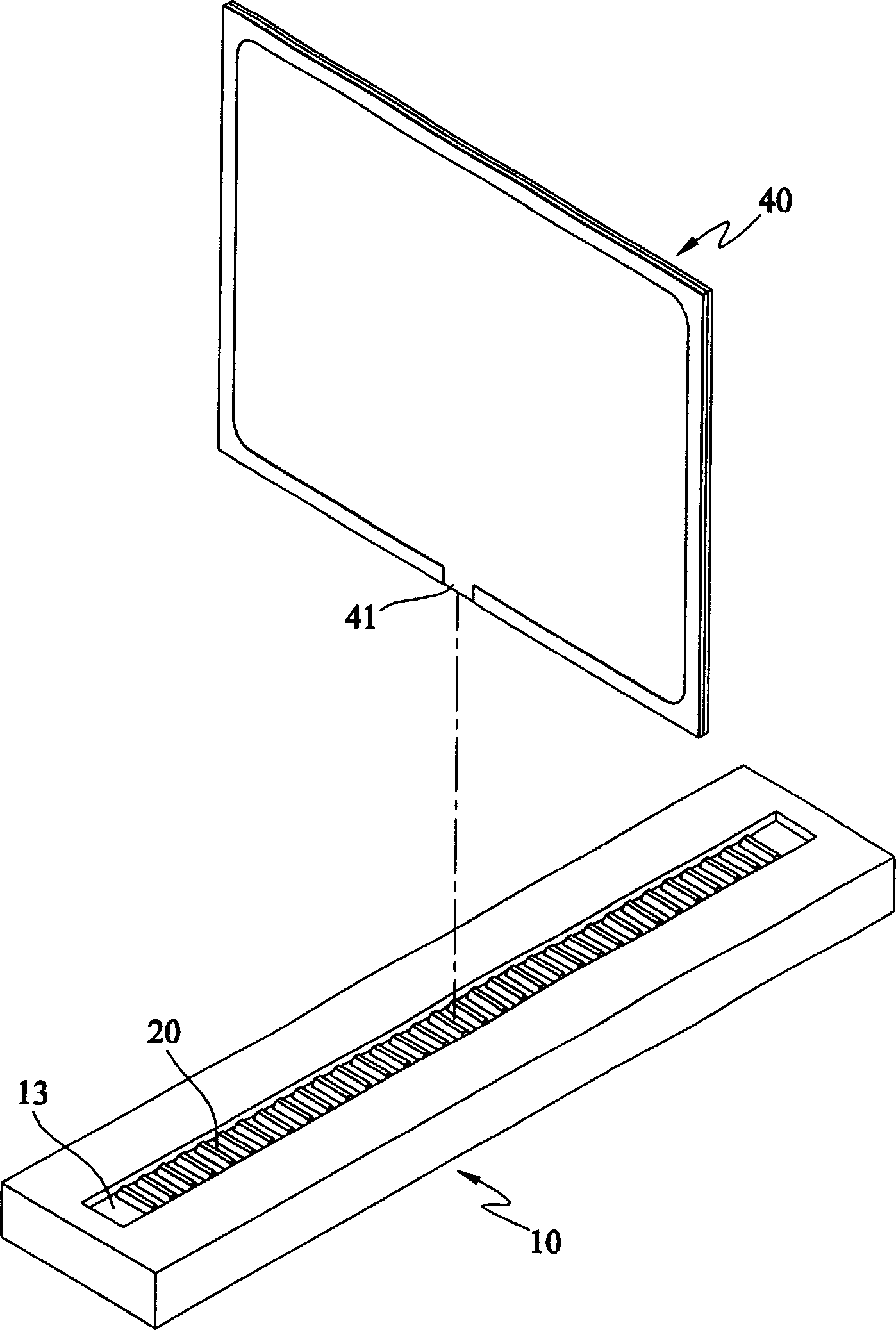

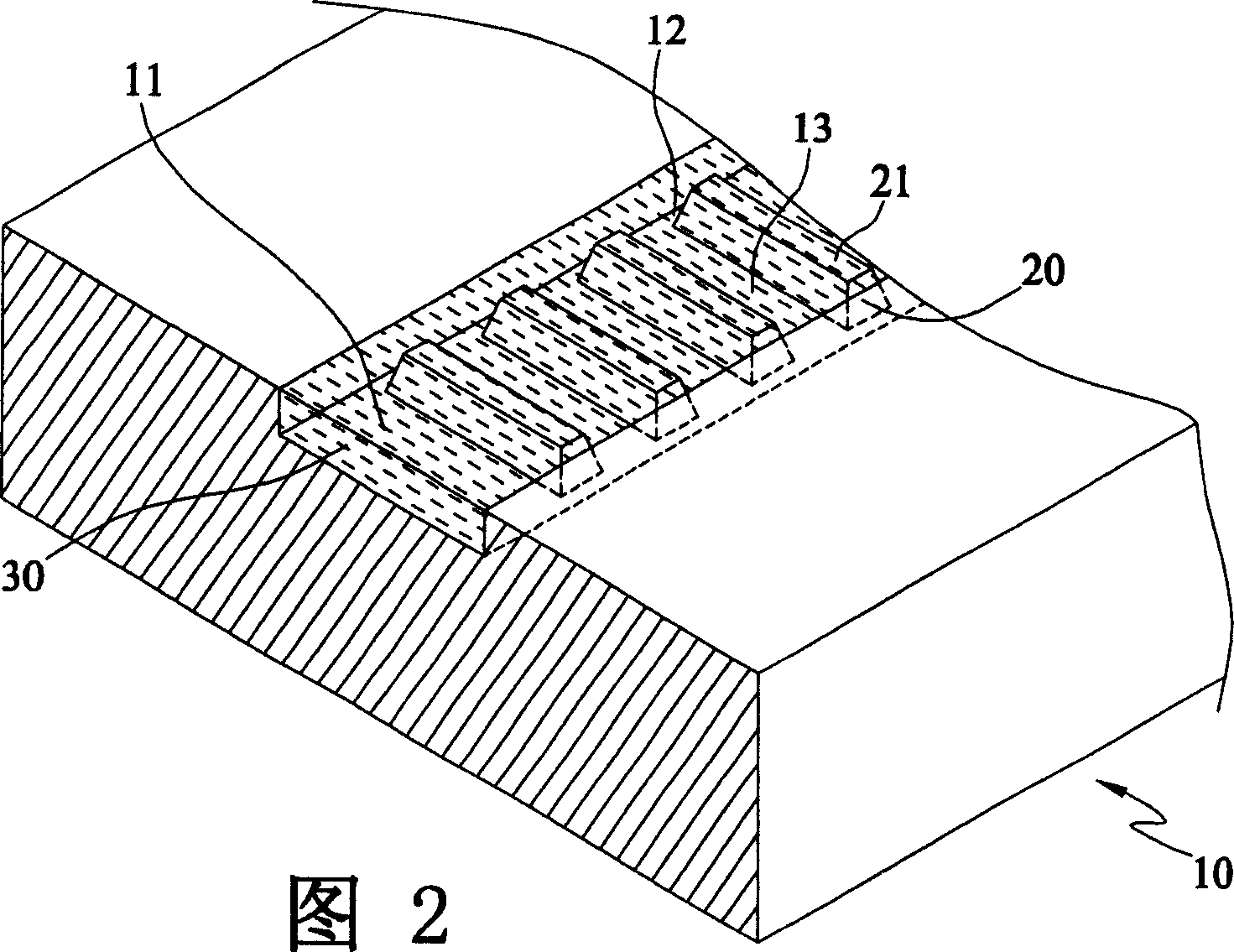

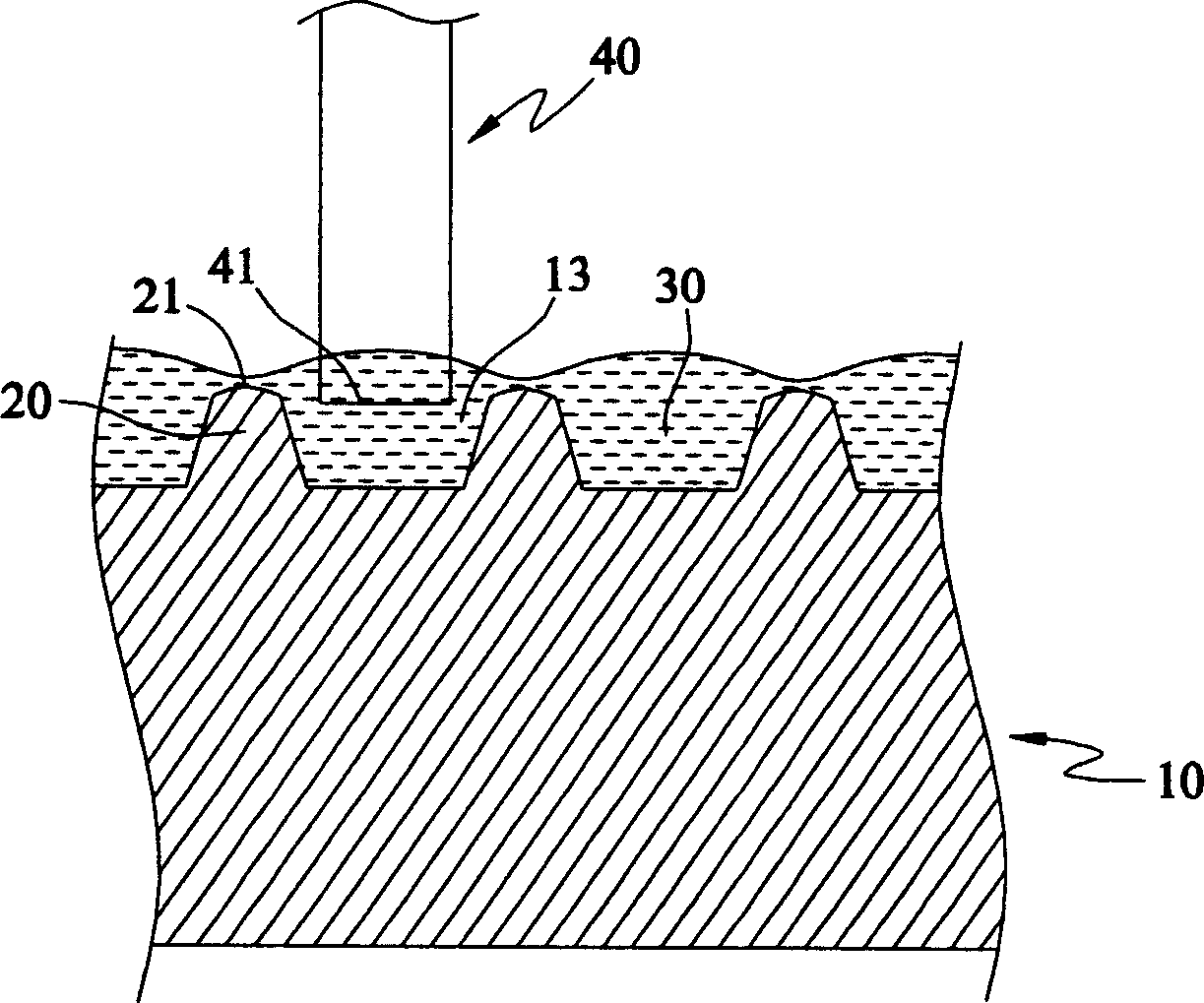

[0024] According to a kind of liquid crystal cell structure disclosed by the present invention, please refer to figure 1 2 to illustrate the first preferred embodiment, wherein the liquid crystal cell 10 has an injection tank 11 for containing liquid liquid crystal material (Liquidcrystal material), the bottom side of the injection tank 11 has several intervals, solid trapezoidal three-dimensional The block-shaped protrusion 20 separates the liquid injection groove 11 into several liquid injection chambers 13 . The top side 21 of the bump 20 has a curved surface. A flow channel 12 with an appropriate width is formed between the liquid injection groove 11 and the protrusion 20 , so that the liquid crystal material 30 stored in the liquid injection groove 11 can freely flow between the liquid injection chambers 13 .

[0025] It should be noted that since the bottom side of the liquid injection tank 11 has several protrusions 20, which occupy the volume space of the liquid injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com