A concentric assembly method and device for regulating same

An adjustment device and assembly method technology, applied in the direction of electromechanical device, casing/housing/support, electrical components, etc., can solve the problem that it is difficult to meet the requirements of high concentricity assembly, it is difficult to grasp the stability and balance of the assembly, and the assembly is reduced. Concentricity of accessories and other issues, to achieve the effect of easy observation, easy control, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

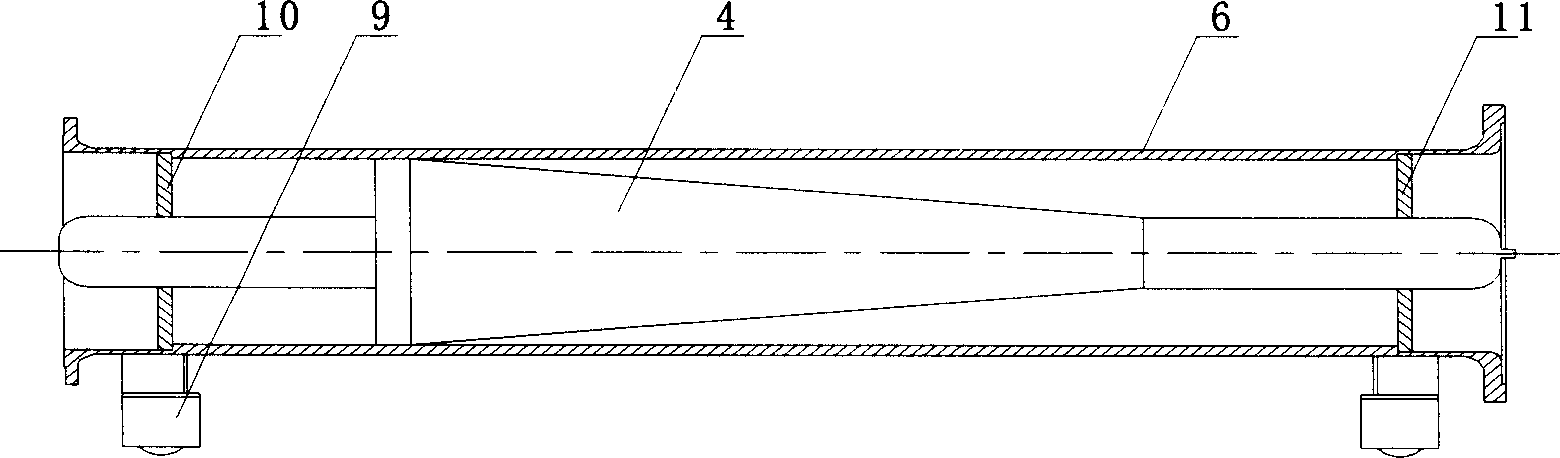

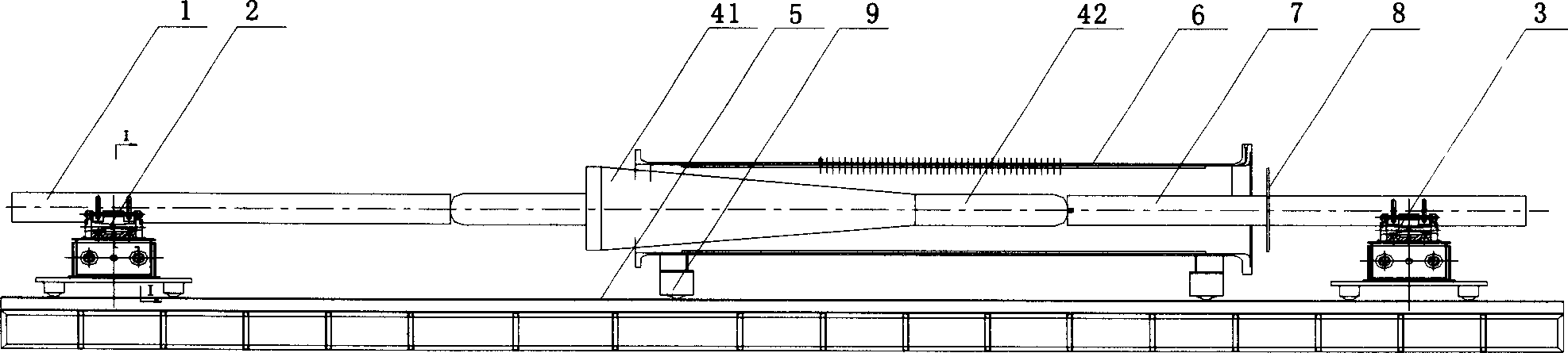

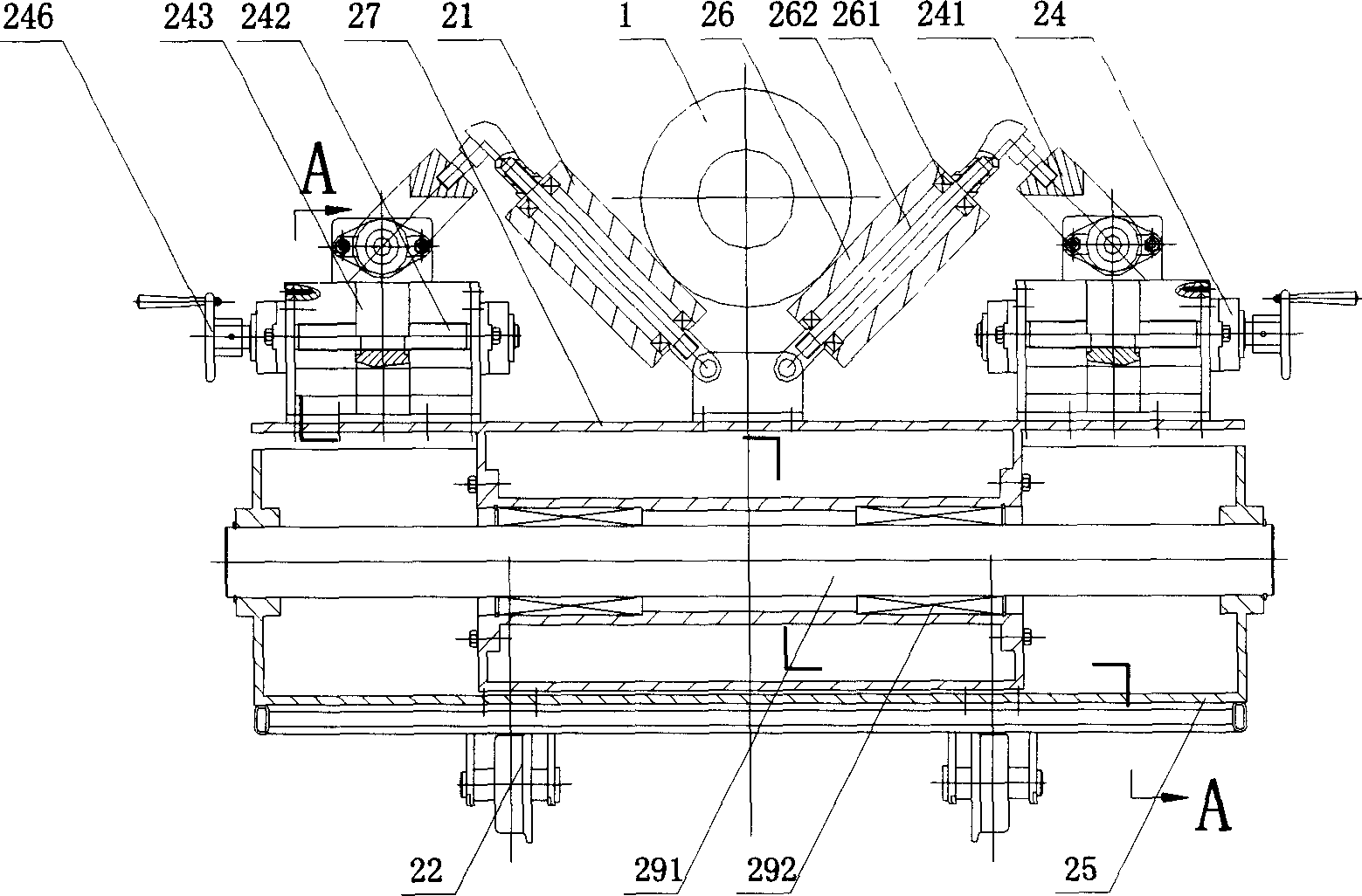

[0016] exist figure 1 , figure 2 Among them, the coaxial pulse transformer is mainly composed of inner iron core 4 and outer iron core 6 . The inner iron core 4 is composed of a conical winding 41 and an iron core 42, and the conical winding 41 and the iron core 42 are fixedly connected together; edge. The outer iron core 6 is arranged on a support 9 with rollers.

[0017] In the concentric assembly process, the large end circumferential surface of the conical winding 41 passes through the inner edge surface of the outer iron core 6, and it must be ensured that the large end circumferential surface of the conical winding 41 of the inner iron core 4 is in contact with the inner edge of the outer iron core 6. The radial gap between the faces is substantially uniform.

[0018] figure 2 It is a schematic diagram of assembly of the present invention. During the concentric assembly process, the inner iron core 4 and the outer iron core 6 are horizontally supported on the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com