Temperature compensation in an electronic circuit toaster

A toaster and bread technology, which is applied in the direction of toasting device, electric temperature control, temperature control, etc., can solve the problem of not being able to have the temperature in the heating room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

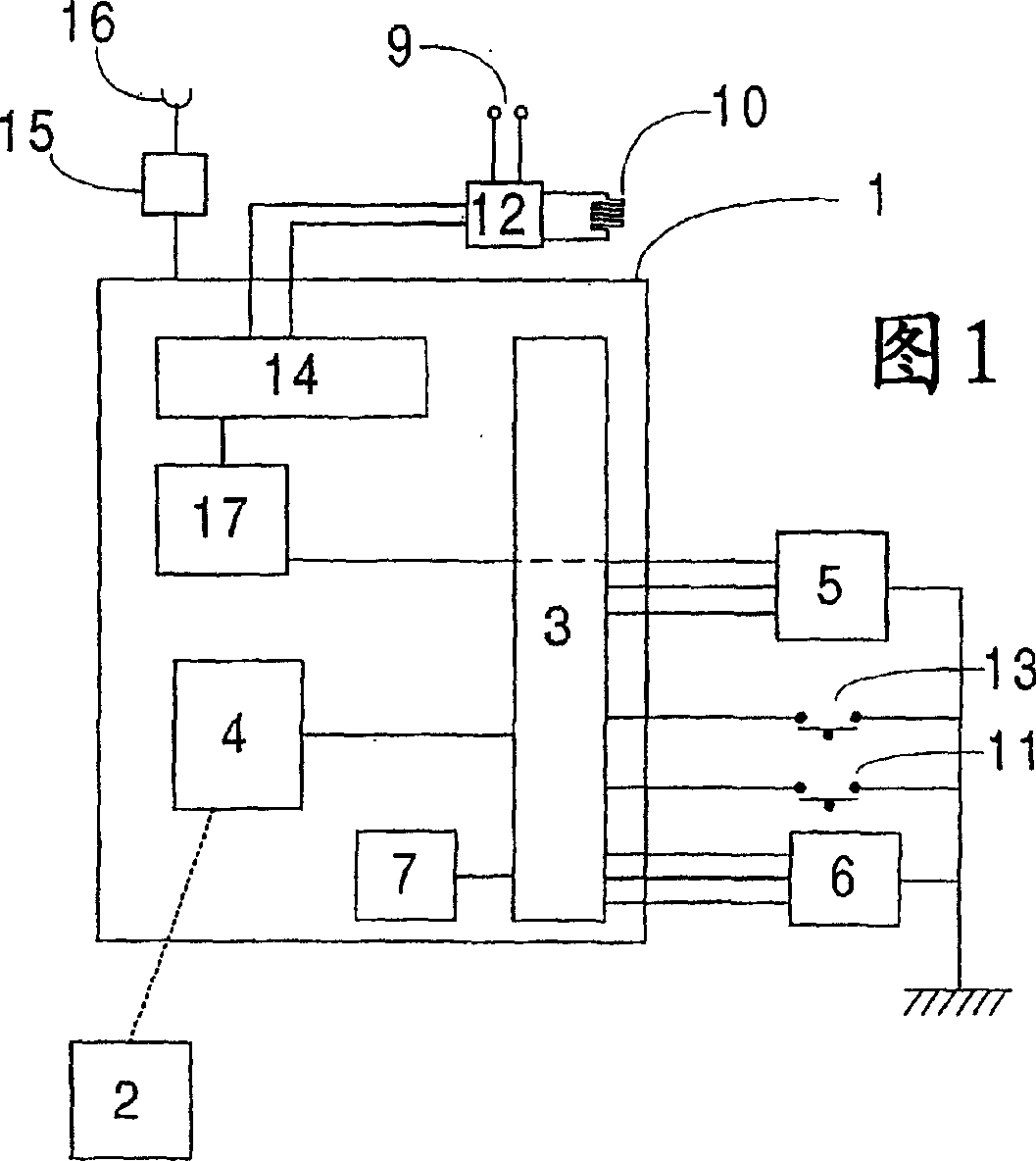

[0031] According to Figure 1, the control structure for mounting on a toaster (not shown) has a microcontroller 1 (schematically shown) with an internal timer 7 and a delay timer 3.

[0032] There is also a roasting process stop switch 11 and a roasting start switch 13 at the input of the microcontroller of FIG. 1 . The former is used to interrupt the toasting process at any moment and send out the bread. The latter can be a button operated by the user, or a switch activated when the bread supporting carriage is in a low position.

[0033] According to the preferred embodiment, an output amplifier unit 14 is used to control a process relay module 12 of the heating element 10, an electromagnet 15 maintains the bread supporting carriage 16 in a low position, and this electromagnet can also communicate with said amplifier. The units are connected or, as in this embodiment, directly controlled by the microcontroller 1 .

[0034] A power supply line, marked 9 in the figure, supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap