Method of fabrication of drip irrigation conduits

A technology of drip irrigation pipes and injectors, which is applied in the field of production of drip irrigation pipes or pipes, can solve the problems of bulky, expensive, and complicated equipment, achieve the effect of omitting detection and punching devices, and increase the production speed of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

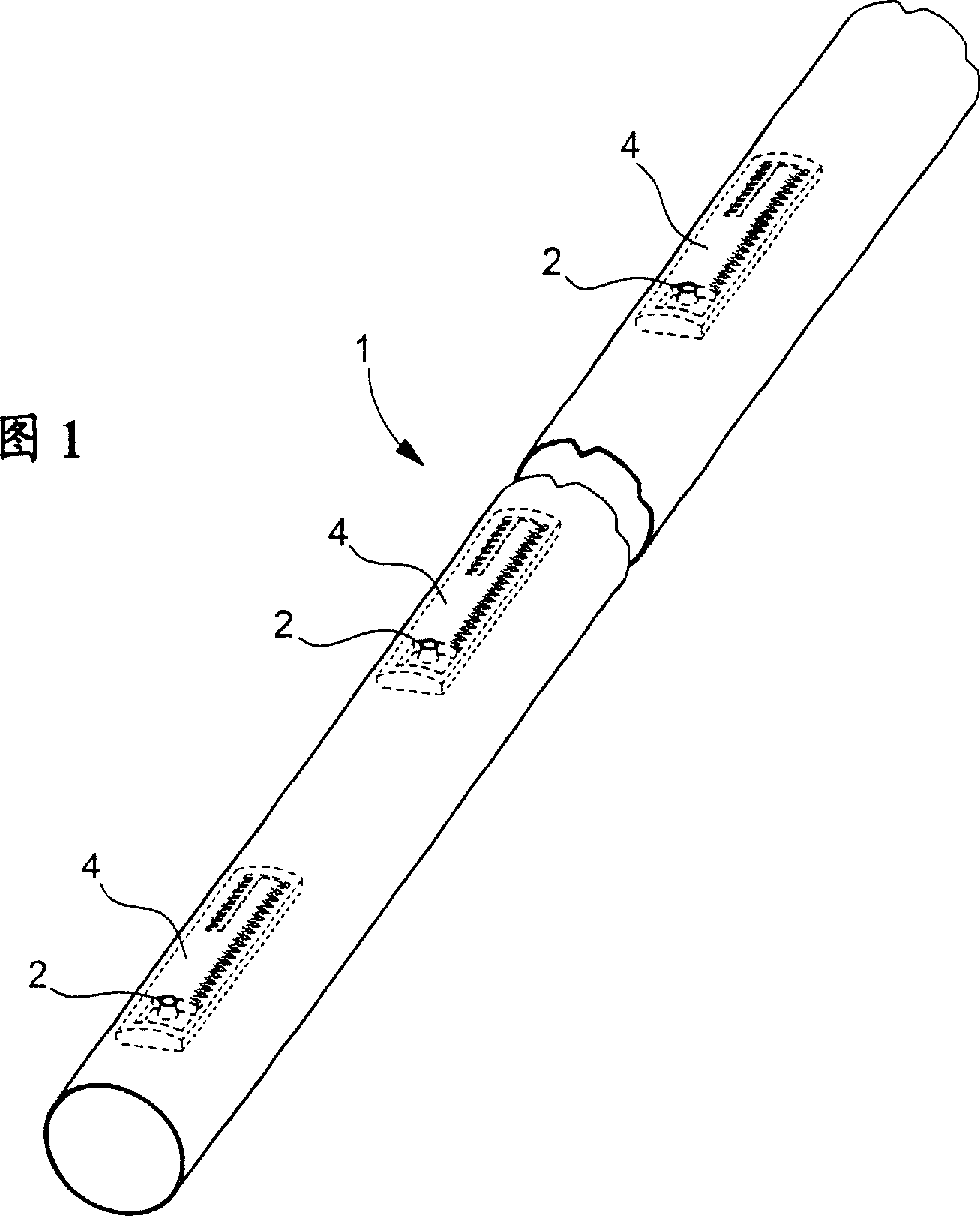

[0035] Figure 1 shows a water supply pipe or pipe 1 made of plastic such as polyethylene having drainage holes or outlets 2 spaced at regular intervals through which water can flow or trickle to aquatic plants (not shown). out). In the vicinity of the hole 2 there is provided an injector 4 placed inside the tube and thus not visible from the outside, the structure of which is explained with reference to FIG. 2 .

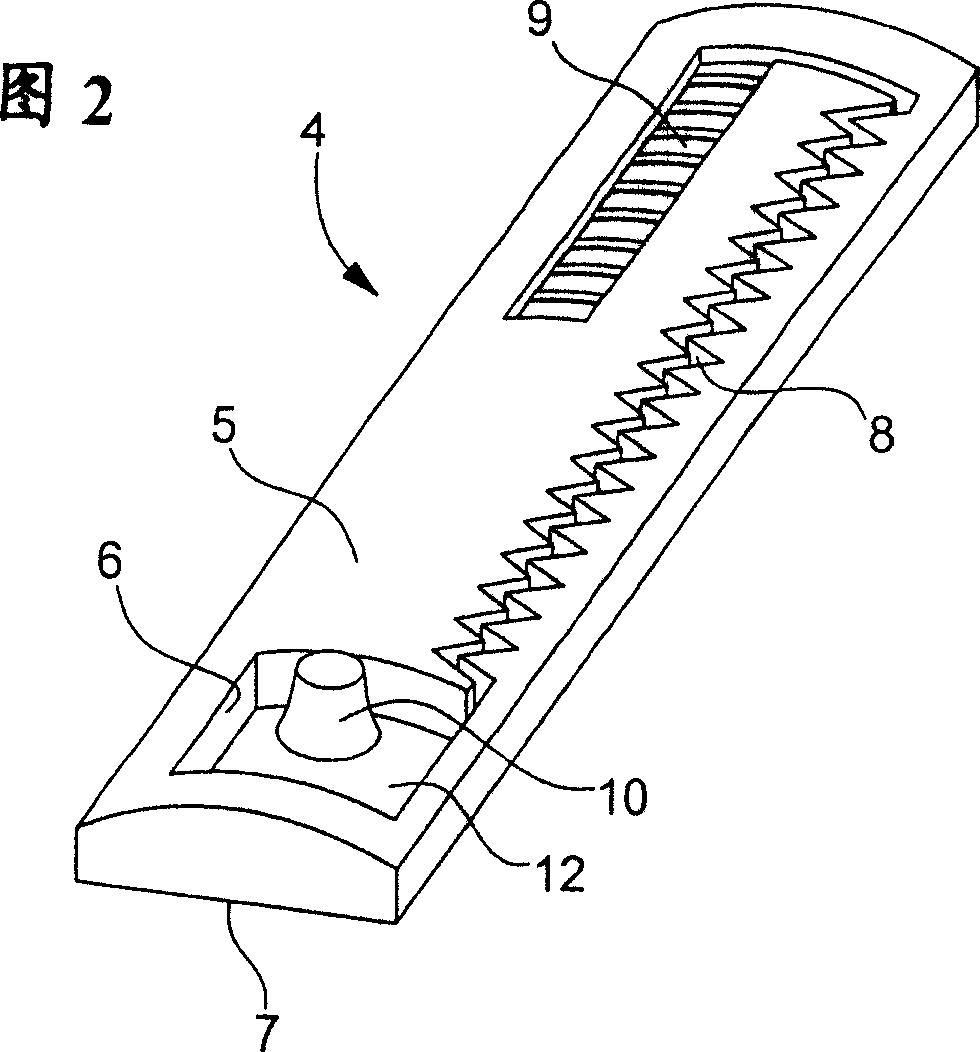

[0036] The injector is a part made of plastic, ideally of the same composition as the pipe 1, although this is not necessary. The injector 4 generally has a body in the shape of an elongated parallelepiped with an “outer” surface 5 whose cross-section has a curvilinear shape corresponding to the curvature of the inner wall of the tube 1 . In the surface 5, a water collection chamber 6 is cut out near the center of substantially one end of the example shown, not reaching the opposite face 7 of the injector. As clearly shown in FIG. 2 , there is provided in the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com