Dispersed red dye composition

A technology of dye composition and disperse red, which is applied in the direction of organic dyes, etc., and can solve problems such as inability to meet dyeing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

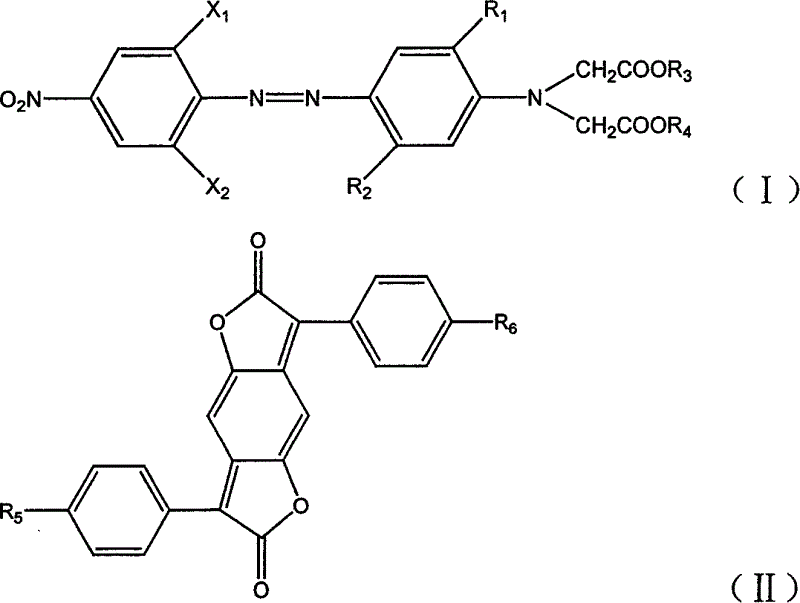

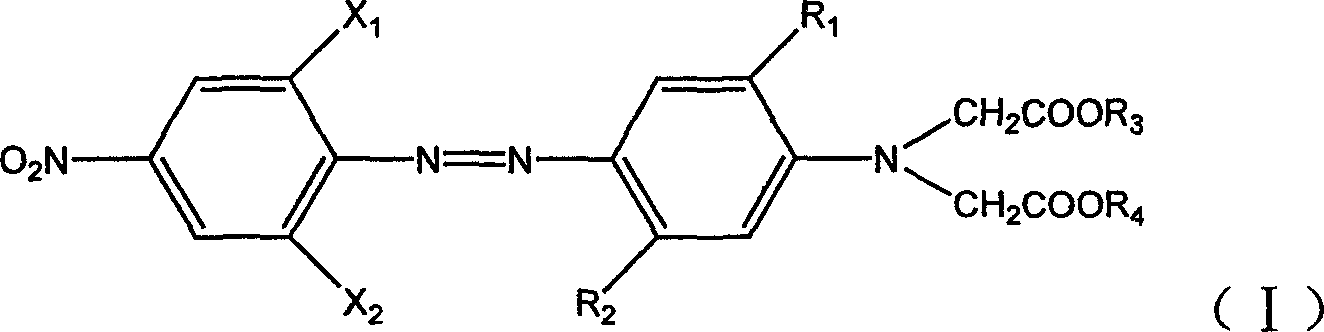

Method used

Image

Examples

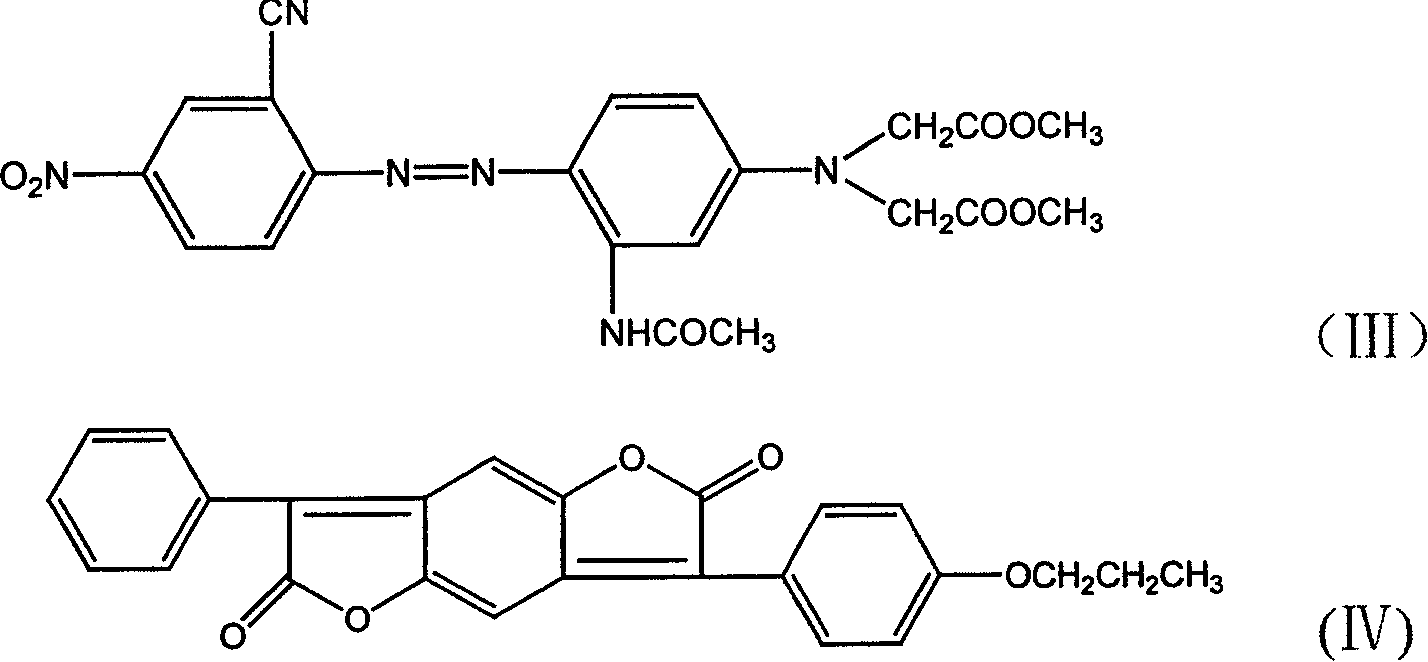

Embodiment 1

[0022] 30 grams of dye A shown in formula (III), 20 grams of dye B shown in formula (IV), 60 grams of dispersant Reax 83A, and 135 grams of pure water are micronized with a sand mill (doing dispersion treatment), Then spray dry to obtain the disperse red dye composition.

Embodiment 2~10

[0024] According to the preparation method of Example 1, the structures of dyes A and B defined by each substituent are shown in Table 1, and the dye composition is blended with dye A and dye B according to the metering data shown in Table 2.

[0025] Example

[0026]

Embodiment 11

[0028] Take 0.5 grams of the disperse dyes prepared in Examples 1 to 10 and disperse them in 500 milliliters of water, absorb 20 milliliters and mix them with 60 milliliters of water, adjust the pH of the dyeing bath to 5 with acetic acid, heat up to 70°C and put 2 grams of poly The polyester fiber is dyed, and the temperature is raised from 70°C to 130°C within 30 minutes, kept at a temperature of 40 minutes, and the sample is taken when it is cooled to 90°C. The color fastness is measured by the national standard GB / T3921-1997, GB / T3920-1997, GB / T5718-1997. The test results are shown in Table 3.

[0029]

[0030] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com