Lithographic printing plate precursor and lithographic printing method

一种平版印刷版、前体的技术,应用在平版印刷版前体领域,能够解决操作错误、印刷版不能识别等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

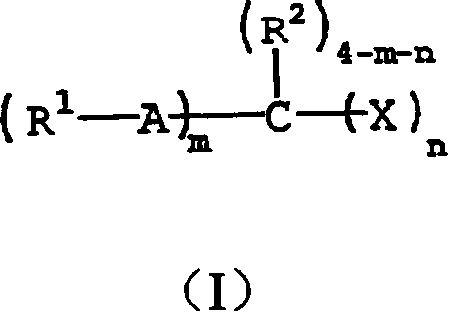

Method used

Image

Examples

Embodiment 1

[0400]

[0401] A 0.3 mm-thick aluminum plate (mechanism material: JIS1050) was degreased at 50° C. for 30 seconds with a 10% by mass aqueous solution of sodium aluminate to remove roll oil on the surface of the plate. Then, by using three nylon brushes inserted with bundled bristles with a diameter of 0.3 mm and an aqueous suspension of pumice with a median diameter of 25 μm (specific gravity: 1.1 g / cm 3 ) to make the surface of the aluminum plate rough, and then wash it thoroughly with water. The plate was immersed in a 25% by mass sodium hydroxide aqueous solution at 45°C for 9 seconds, then washed with water, immersed in 20% by mass of nitric acid at 60°C for 20 seconds, and then washed with water. At this time, the amount of etching on the granular surface is about 3g / m 2 .

[0402] Then, the Al plates were subjected to continuous electrochemical surface roughening using AC at 60 Hz. The electrolytic solution used here is a 1% by mass nitric acid aqueous solution (co...

Embodiment 2

[0437] A coating solution (2) for a photosensitive-thermosensitive layer except having the following components was bar-coated and then dried in an oven at 100°C for 60 seconds to form 2 A lithographic printing plate precursor was obtained in the same manner as in Example 1 except for the dry coating amount of the photosensitive-thermosensitive layer.

[0438] Coating solutions for photo-thermo-sensitive layers (2):

[0439] Infrared absorber (1) 0.3g

[0440] Polymerization initiator (1) 0.9g

[0441] Binder polymer (1) shown below 2.5g

[0442] Polymerizable compound Isocyanuric acid EO-modified triacrylate, (NK Ester M-315, manufactured by Shin-Nakamura Chemical Co., Ltd.) 5.4 g

[0443] Triazine compound (1) 0.1g

[0444] Colorless crystal violet (manufactured by Tokyo Kasei Kogyo Co., Ltd.) 0.8 g

[0445] Fluorosurfactant (1) 0.1g

[0446] Methanol 4g

[0447] Methyl ethyl ketone 96g

[0448] Binder polymer (1):

[0449]

[0450] Weight average molecular weigh...

Embodiment 3

[0452] A coating solution (3) for a photosensitive-thermosensitive layer except having the following components was bar-coated and then dried in an oven at 80°C for 60 seconds to form 2 A lithographic printing plate precursor was obtained in the same manner as in Example 1 except for the dry coating amount of the photosensitive-thermosensitive layer.

[0453] Coating solution (3) for photo-thermosensitive layer:

[0454] Infrared absorber (2) shown below 0.3g

[0455] Polymerization initiator (1) 0.9g

[0456] Binder polymer (1) 2.5g

[0457] Polymerizable compound Pentaerythritol triacrylate (SR444, manufactured by Nippon Kayaku Co., Ltd.) 5.4 g

[0458] Microcapsules (2) (based on solid content) 2.5g

[0459] Fluorosurfactant (1) 0.1g

[0460] Methanol 10g

[0461] water 35g

[0462] Propylene Glycol Monomethyl Ether 50g

[0463] Infrared absorber (2):

[0464]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com