Experimental method for appraising ABB controlling level by sliding rate

A test method and slip rate technology, applied in vehicle testing, machine/structural component testing, braking safety systems, etc., can solve the problem of poor intuition, uncertainty of test results, difficulty in obtaining ABS control evaluation results, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

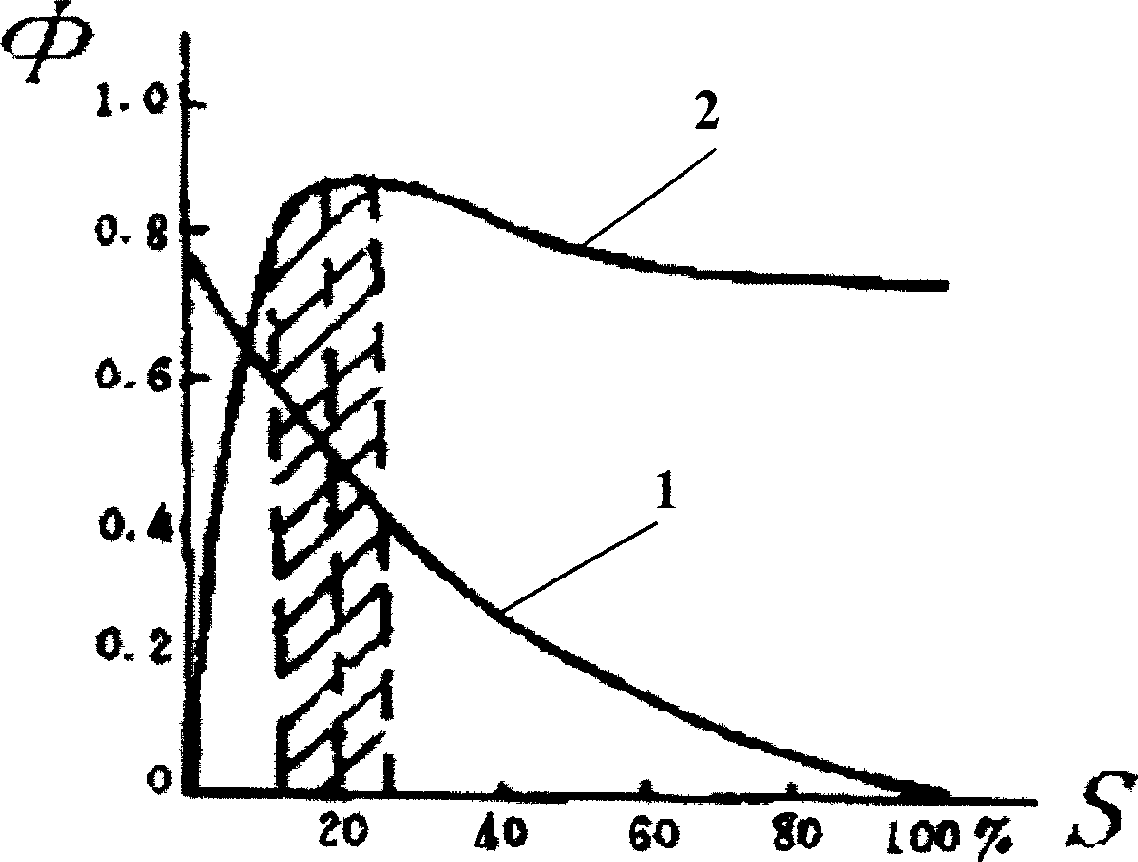

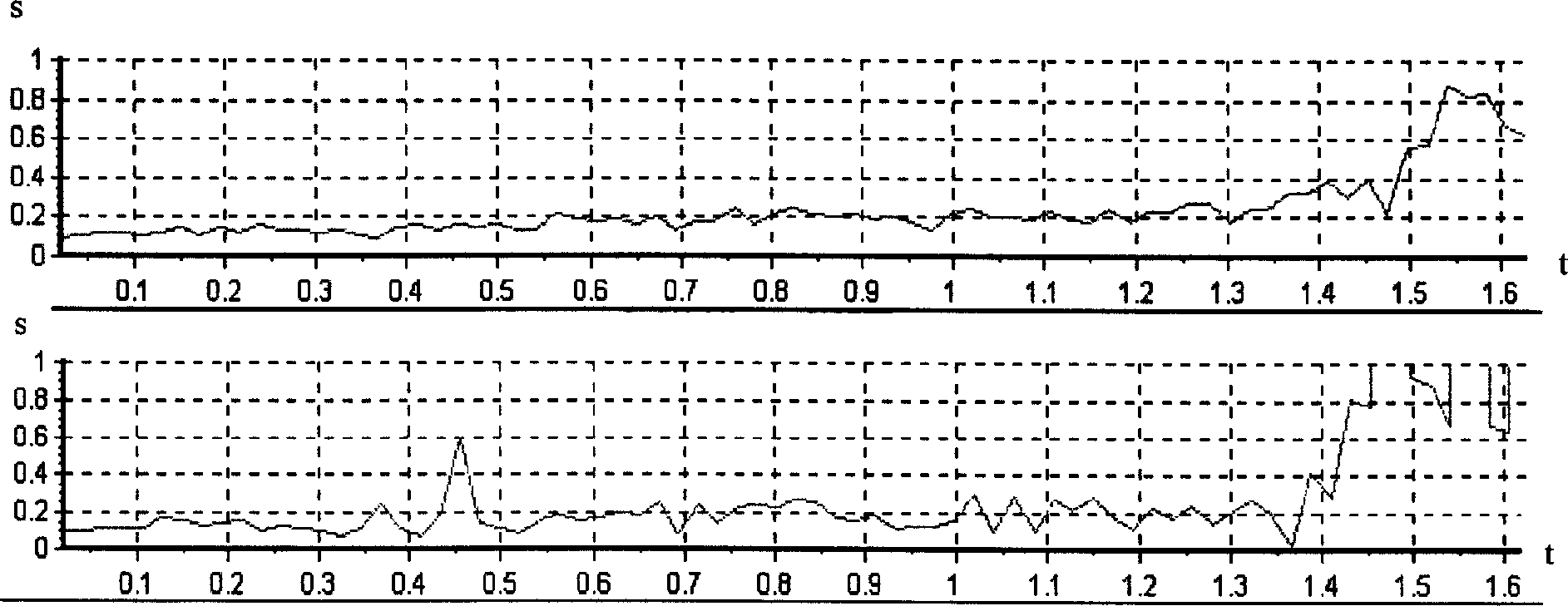

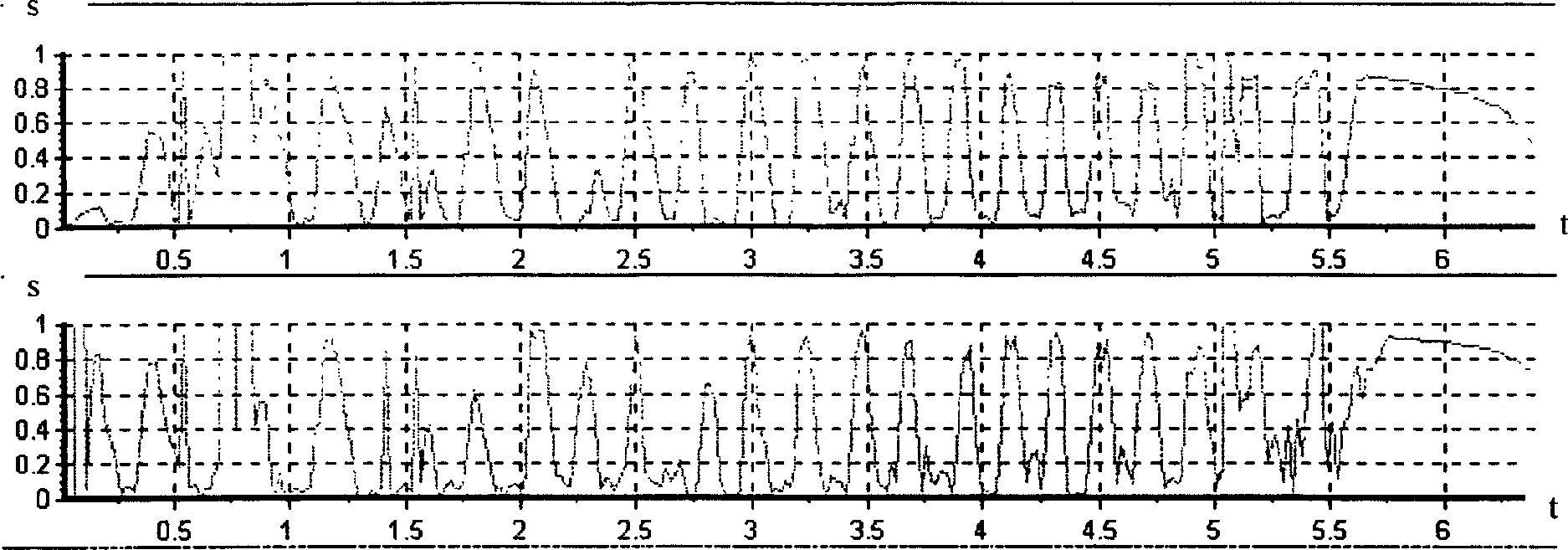

[0026] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail: through theoretical analysis and the ABS test method that adopts at home and abroad at present is analyzed and researched, proposes to describe the ABS control process with the slip rate change of each wheel in the braking process experiment method. Firstly, measure the slip rate-vehicle speed curve and slip rate-time curve of each wheel during the braking process of the vehicle, and then compare the above curves with the adhesion coefficient-slip rate curve of the test road surface to directly obtain any The adhesion status of each wheel at a time, so as to directly evaluate the adjustment level of ABS. Because the adhesion coefficient is an important parameter to evaluate the adhesion state of the wheel, and the adhesion coefficient is closely related to the slip rate, so the slip rate-vehicle speed curve and the slip rate-time curve are compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com