Carbonated water manufacturing device, water purifier with the device, and stationary water purifier

A technology for manufacturing devices and carbonated water, which is applied in distribution devices, adsorbed water/sewage treatment, added substance water/sewage treatment, etc., and can solve the problems of being fixed in a desired position, leaking water spray pipes, and difficult to use as usual, and achieves Simple composition, improved taste, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings.

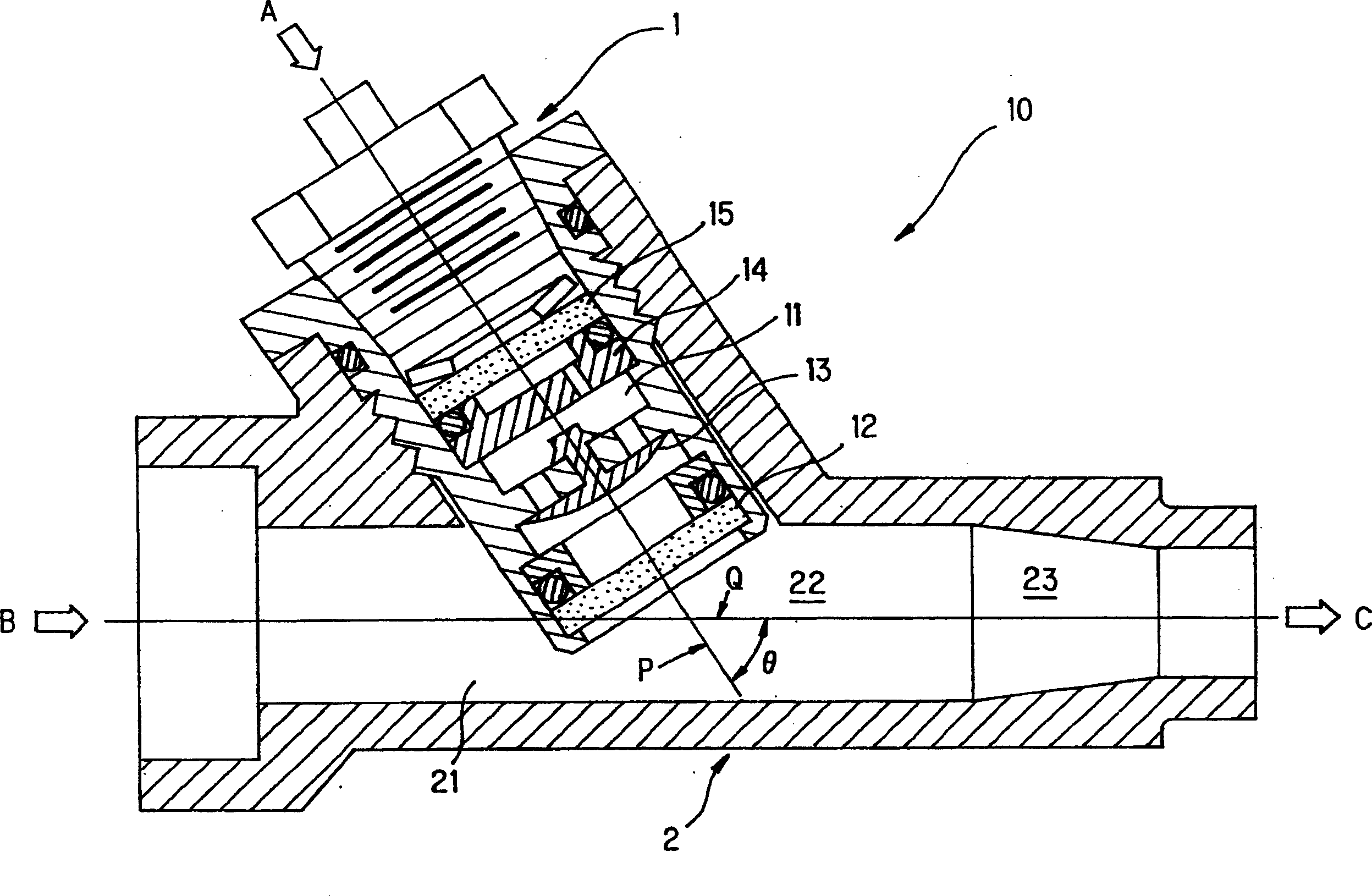

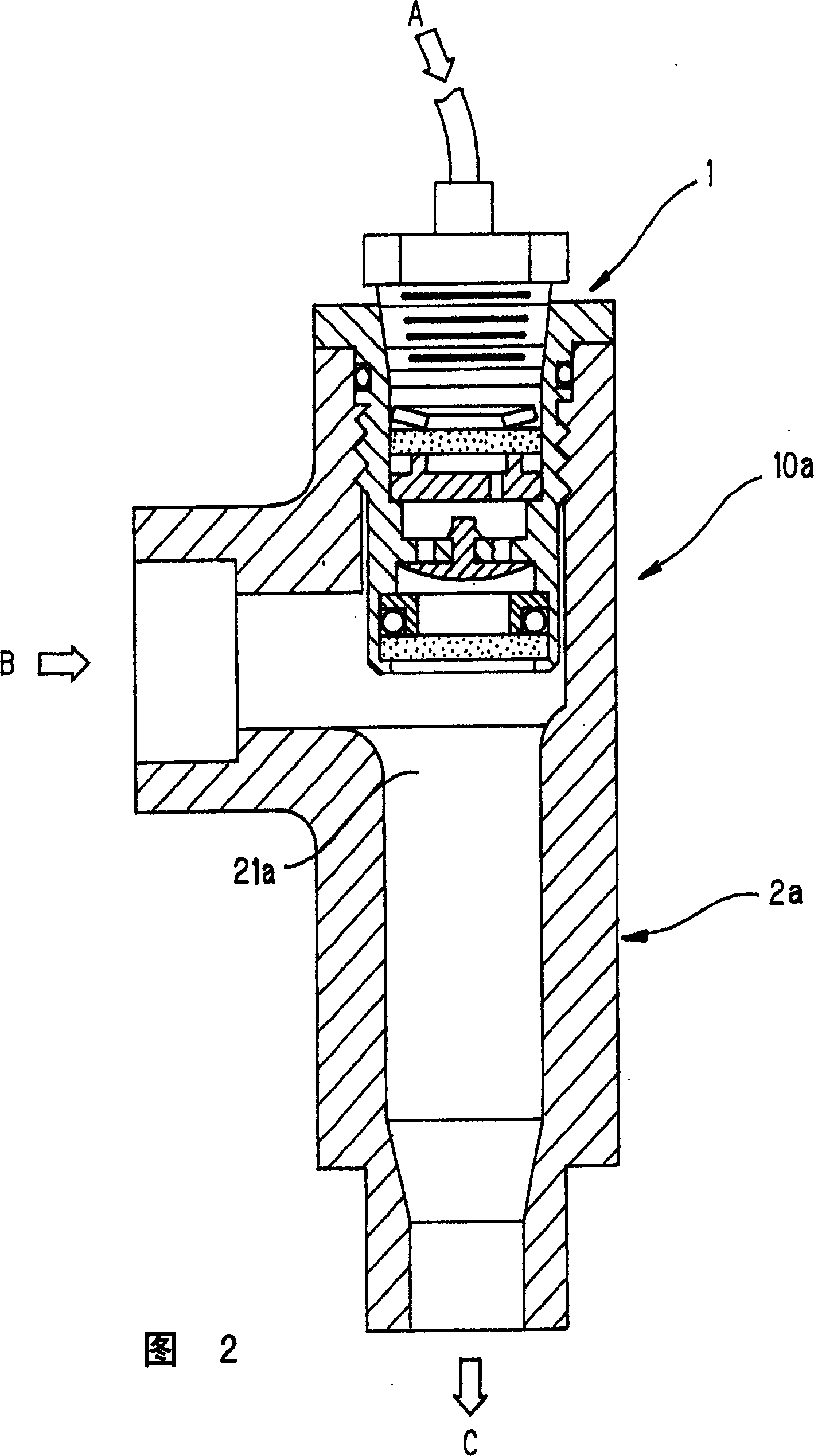

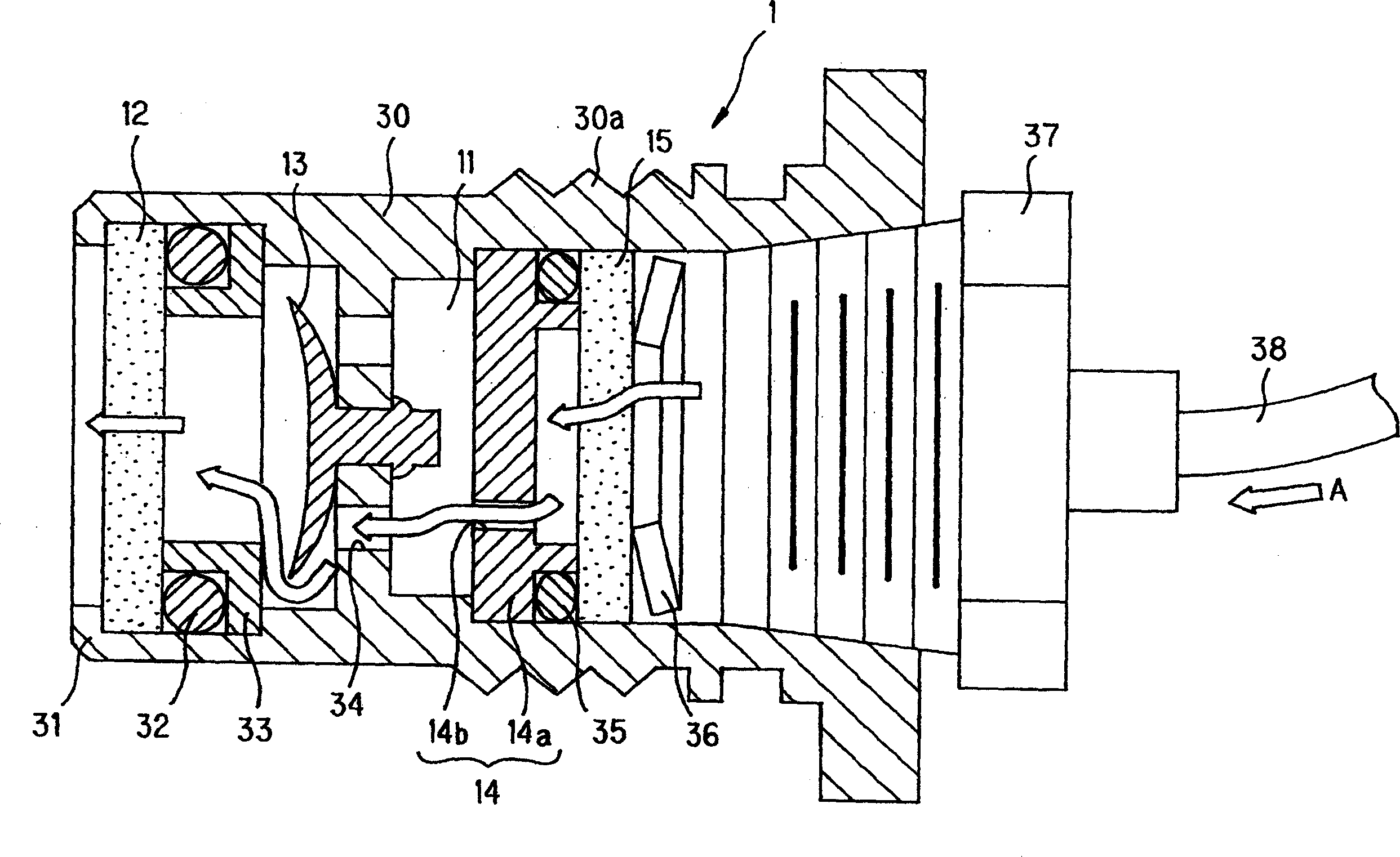

[0078] figure 1 It is a cross-sectional view schematically showing an embodiment of the carbonated water manufacturing apparatus of the present invention (first invention).

[0079] Such as figure 1 As shown, the carbonated water manufacturing device of this embodiment is provided with a carbon dioxide gas supply part 1 having a carbon dioxide gas flow channel 11 and supplying carbon dioxide gas A through the carbon dioxide gas flow channel 11, having a water flow channel 21 and mixing The carbon dioxide gas A supplied by the carbon dioxide supply part 1 and the water B continuously passing through the water flow channel 21 are used to produce the carbonated water production device 10 of the mixing part 2 of the carbonated water C. It is characterized in that the carbon dioxide supply part 1 and the mixing part 2 Wearing is fixed freely.

[0080] Here,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap