Cathode ray tube-use glass panel and inspection method therefore and inspection device therefor

A cathode ray tube and glass panel technology, which is applied to cathode ray/electron beam tube shells/containers, measuring devices, screen tubes, etc., can solve the problems of improper disposal of vacuum tubes and three-dimensional complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

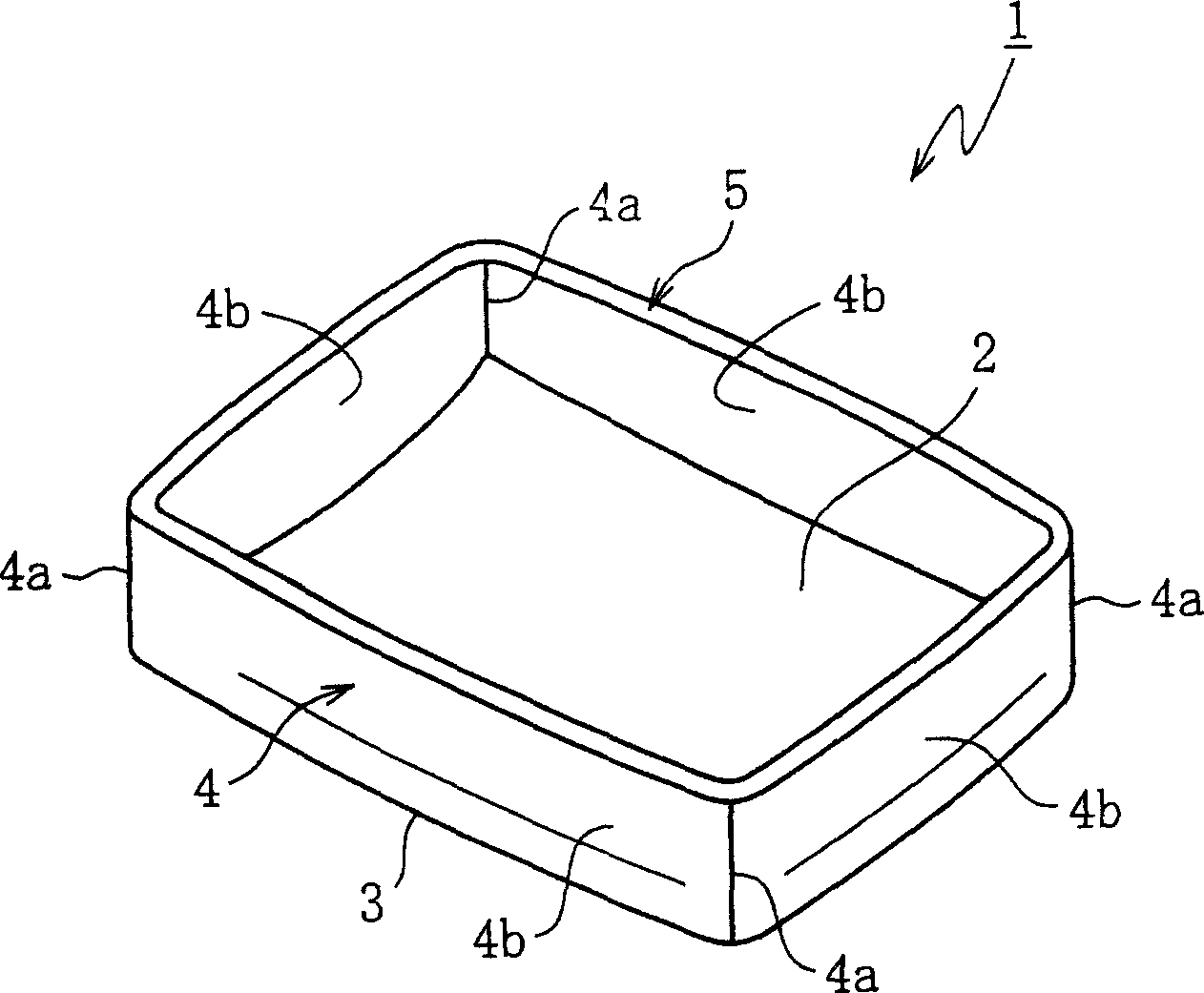

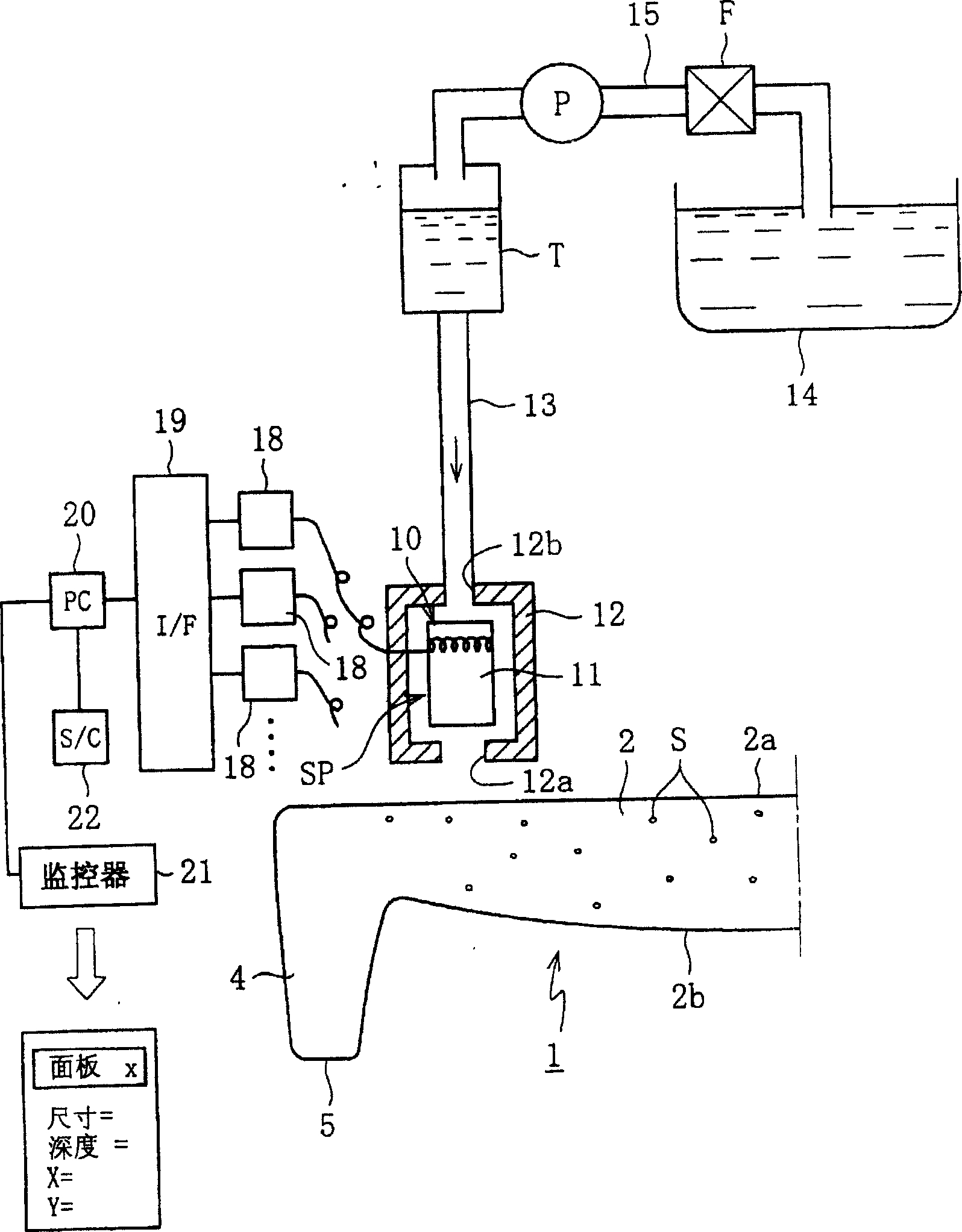

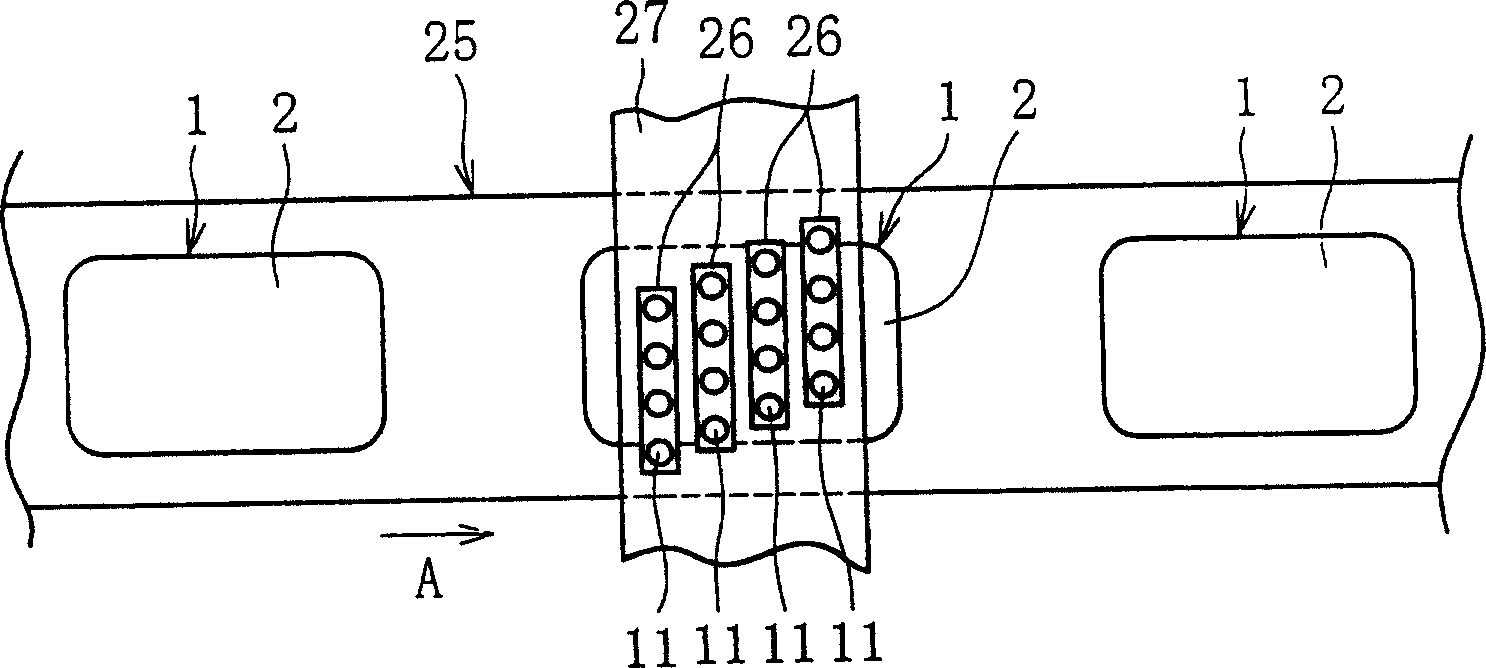

[0073] Hereinafter, description will be given based on drawings of embodiments of the present invention. figure 1 Shown is a perspective view of a glass panel for a projection type cathode ray tube (hereinafter simply referred to as a panel) according to an embodiment of the present invention. figure 2 Shown is a schematic front view of the main part of the detection device of the panel. FIG. 3(a) is a schematic plan view of the entire detection device. Fig. 3(b) is a schematic front view of the entire detection device.

[0074] Such as figure 1As shown, the panel 1 is provided with: a screen portion 2 that is equipped with an effective image display; an edge portion that is connected at a substantially right angle around the screen portion 2 by a mixed R portion 3 around the screen portion 2 4. Also, the edge portion 4 has each side portion 4b connected by four diagonal portions 4a, and an end face 5 sealed at the joint of the funnel is formed at the opening of the front...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap