Electric control one-way valve

An electronically controlled one-way valve, one-way valve technology, applied in the direction of control valve, valve details, valve device, etc., can solve the problems of heavy weight, difficult to control leakage, complex structure, etc., and achieve the effect of simple structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

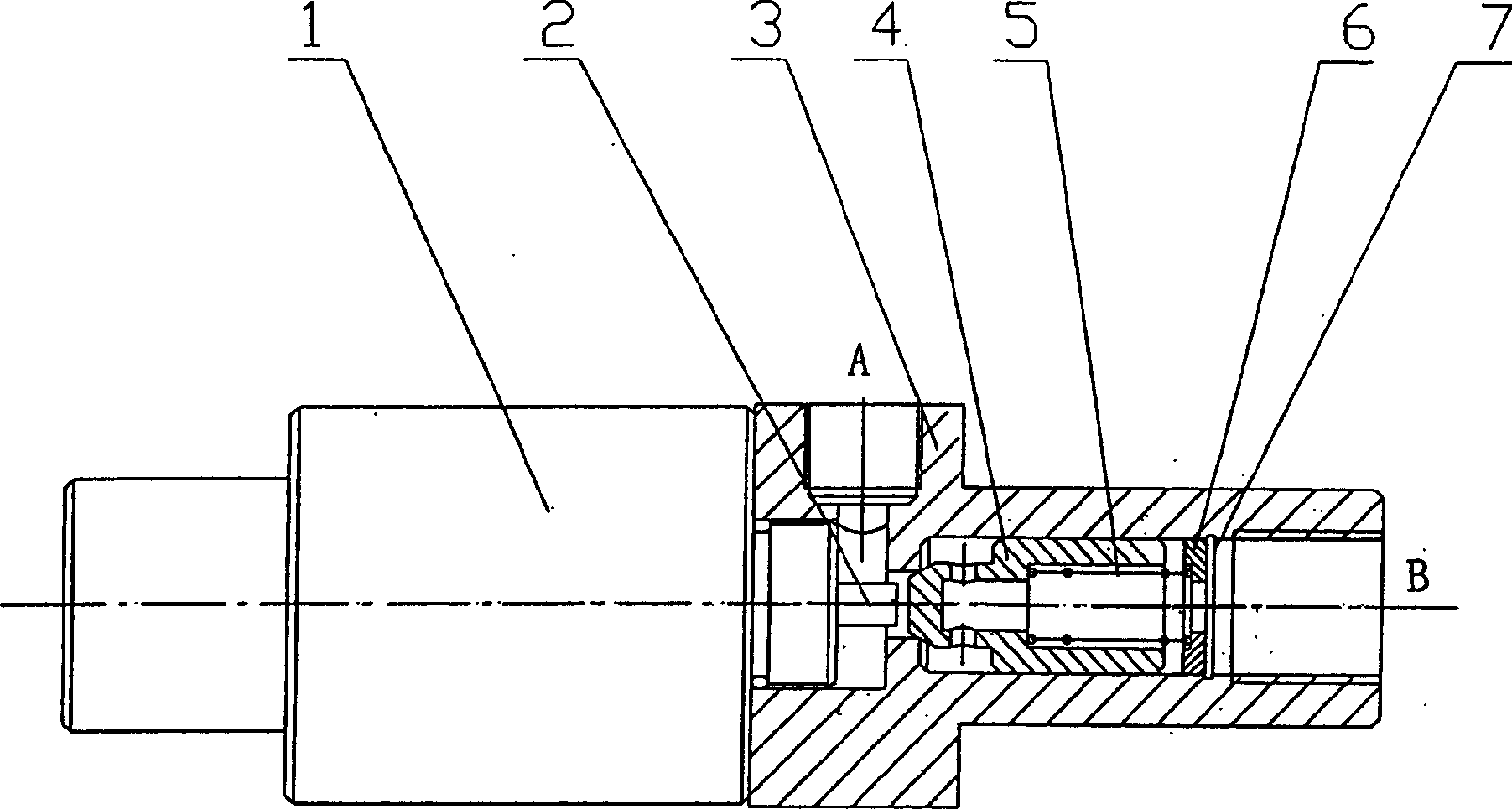

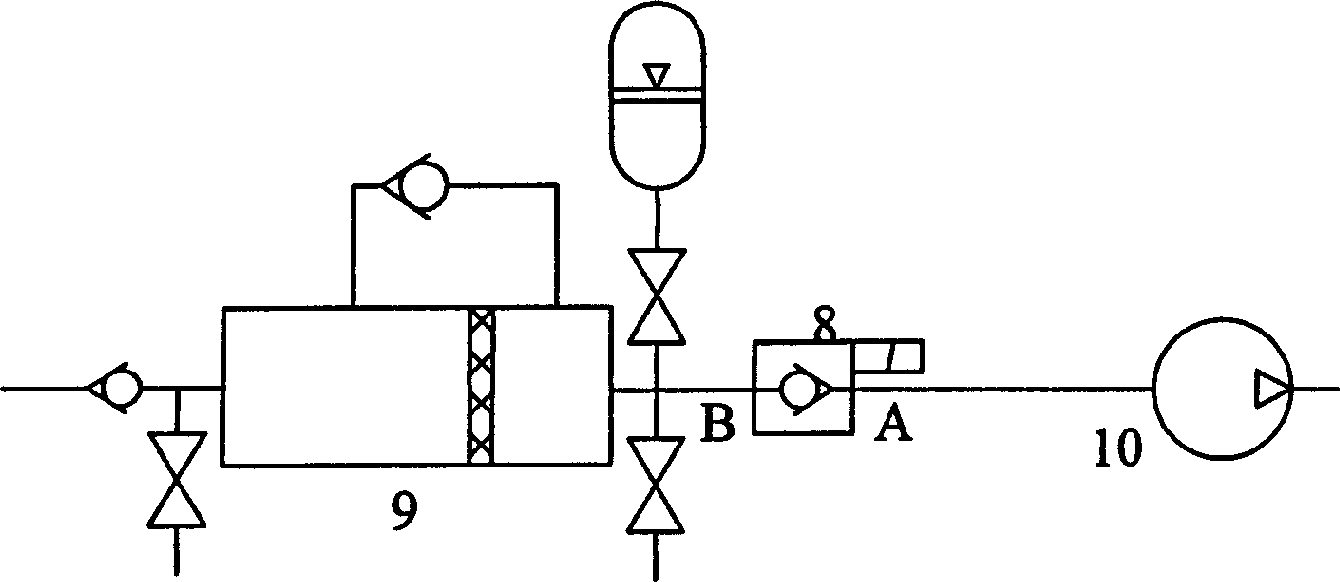

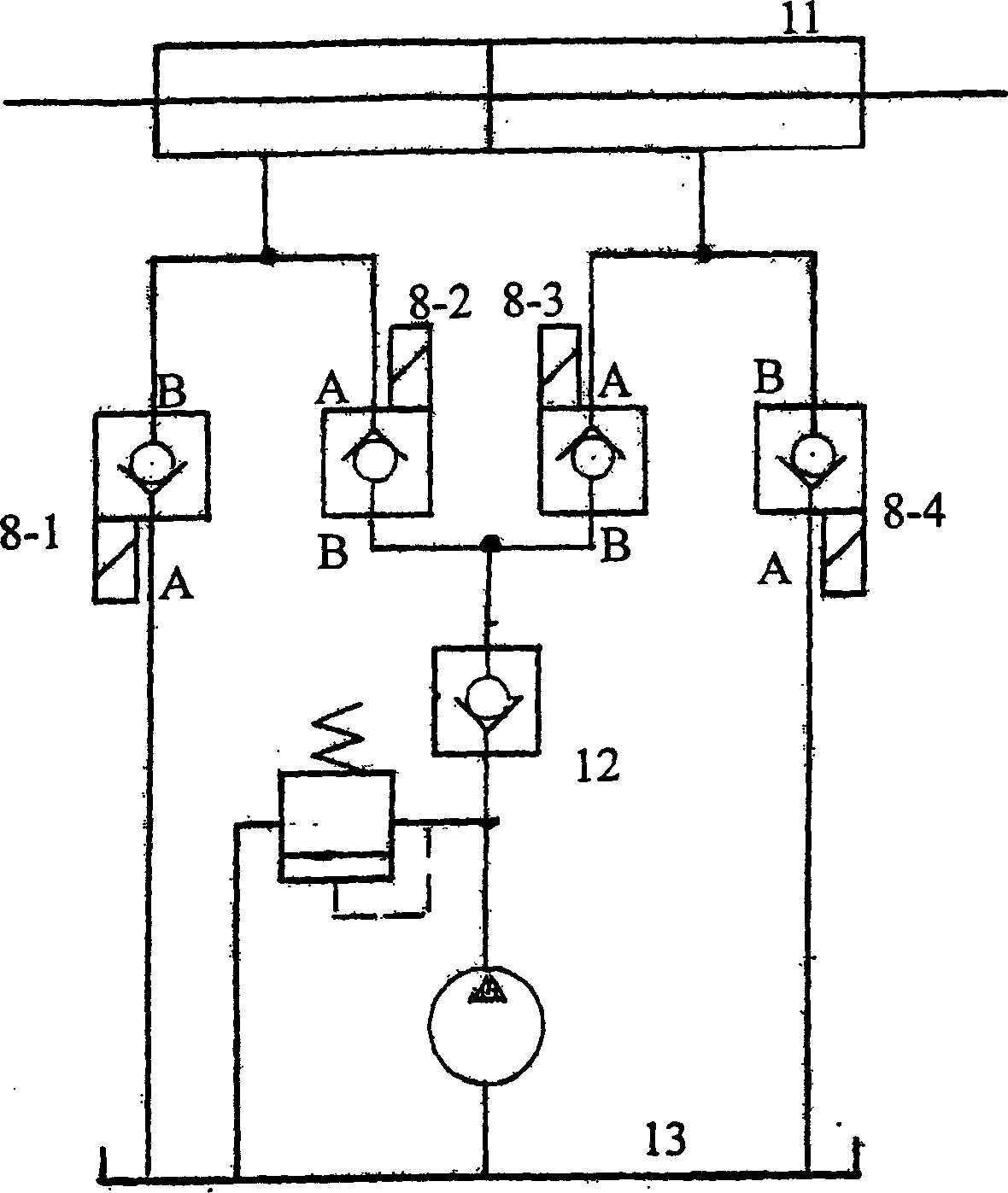

[0015] Such as figure 1 Shown, the present invention is made up of electromagnet 1 and check valve. The one-way valve includes a valve body 3, a valve core 4 and a snap ring 7; an oil port A is opened on one side of the valve body 3, and an axial through hole is opened in the axial direction of the valve body 3, and the middle is a joint One side of the throttle hole is oil port A, and the axial through hole of the valve body 3 on the other side of the throttle hole is equipped with a valve core 4 and a retaining ring 7 in sequence from the inside to the outside, and the hole end is an oil port. Port B, the spool 4 is stepped, the tapered surface of the small end of the spool 4 matches the orifice, and the side of the small end of the spool 4 has a hole connecting the inner hole of the spool 4 and the axial through hole of the valve body 3 Oil hole; the electromagnet push rod 2 of the electromagnet 1 is housed in the axial through hole of the valve body 3 on one side of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com