Automated endoscope reprocessor

A reprocessing and container technology, applied in the direction of endoscopy, chemical instruments and methods, applications, etc., can solve problems such as pressure reduction in the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

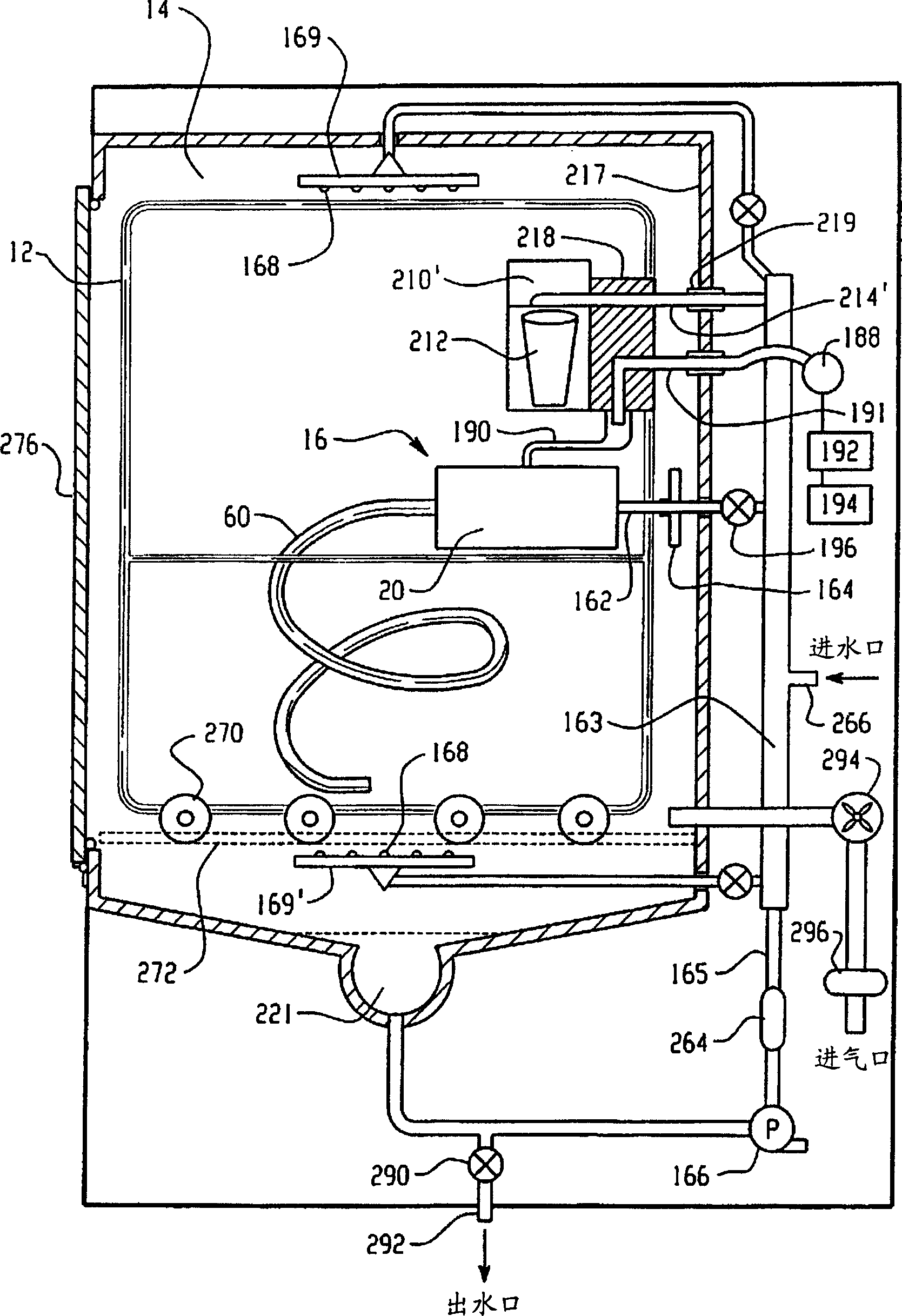

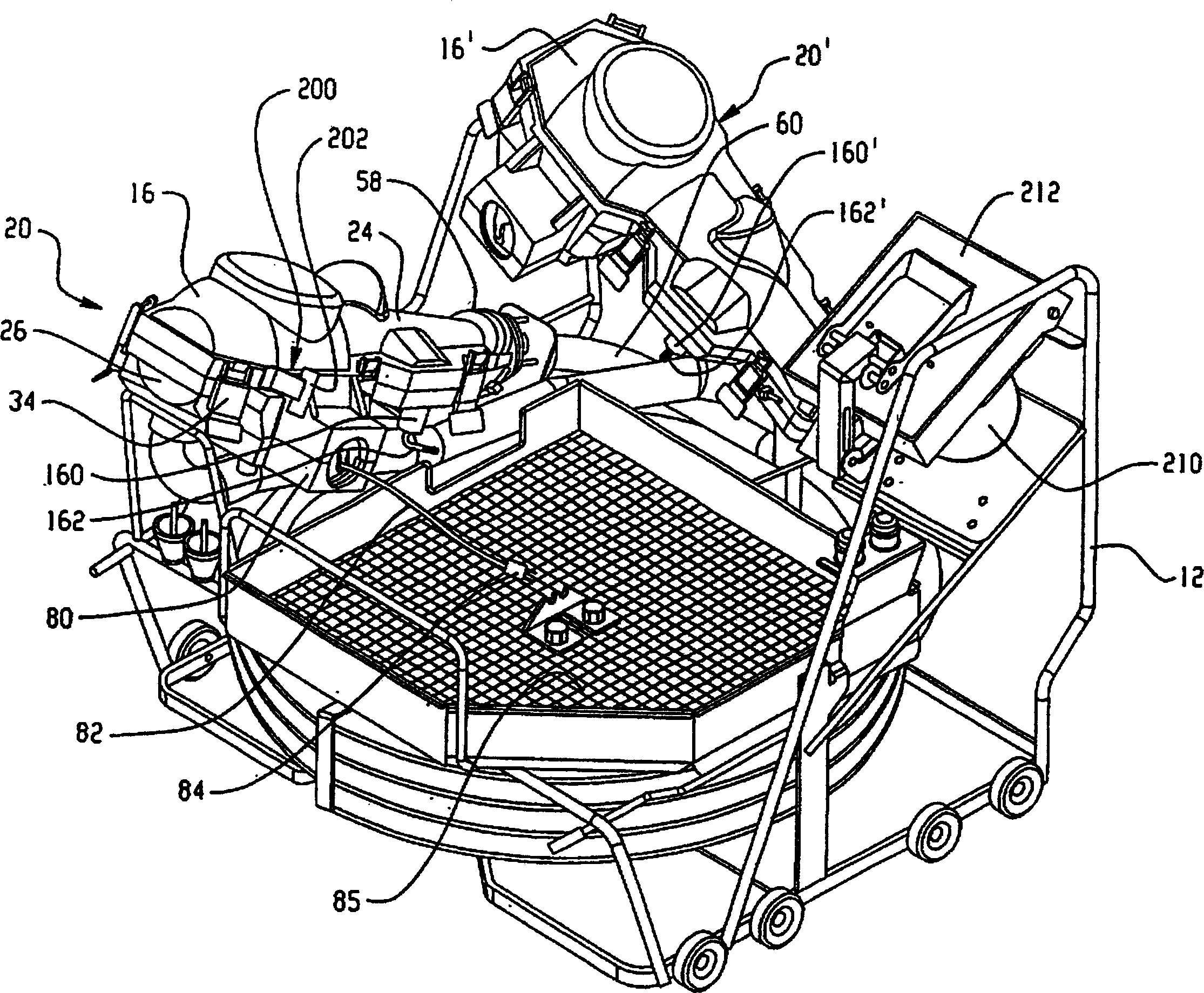

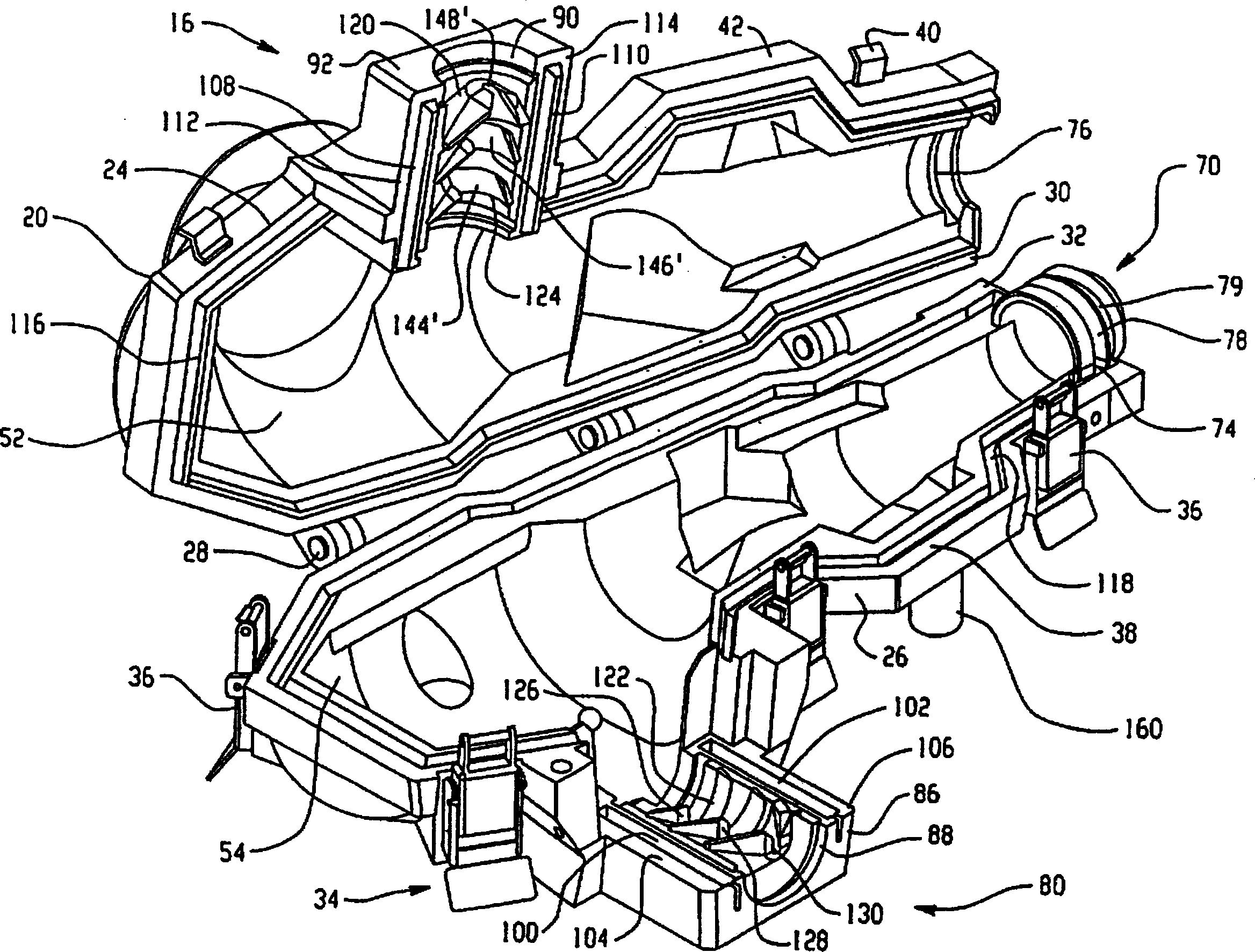

[0036] refer to figure 1 An automated endoscope reprocessor 10 is configured to receive a wheeled cart or rack 12 in a washing / disinfecting chamber 14 for rolling reception. The reprocessor volume 14 preferably has an internal volume of about 10-15 liters. The processor is sized to fit an underlying countertop or other work surface. However, higher mounting positions and processors of other sizes are also contemplated.

[0037] The reprocessor 10 described herein will be described with particular reference to the cleaning and sanitizing steps (generally referred to herein as reprocessing), but it is also contemplated that these steps may be optimally combined, either using additional steps, or subtracting one or more steps. steps. In addition, disinfection usually refers to the destruction or inactivation of all harmful microorganisms, but a higher level of antimicrobial treatment can also be considered, such as sterilization (destruction or inactivation of all harmful or h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com