Lens for a vehicular lamp and manufacturing method for the same

一种灯具、车辆的技术,应用在家里用具、车辆部件、车辆照明系统等方向,能够解决有损配光镜美观等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the best mode for implementing the vehicle lamp and its manufacturing method according to the present invention will be described with reference to the drawings.

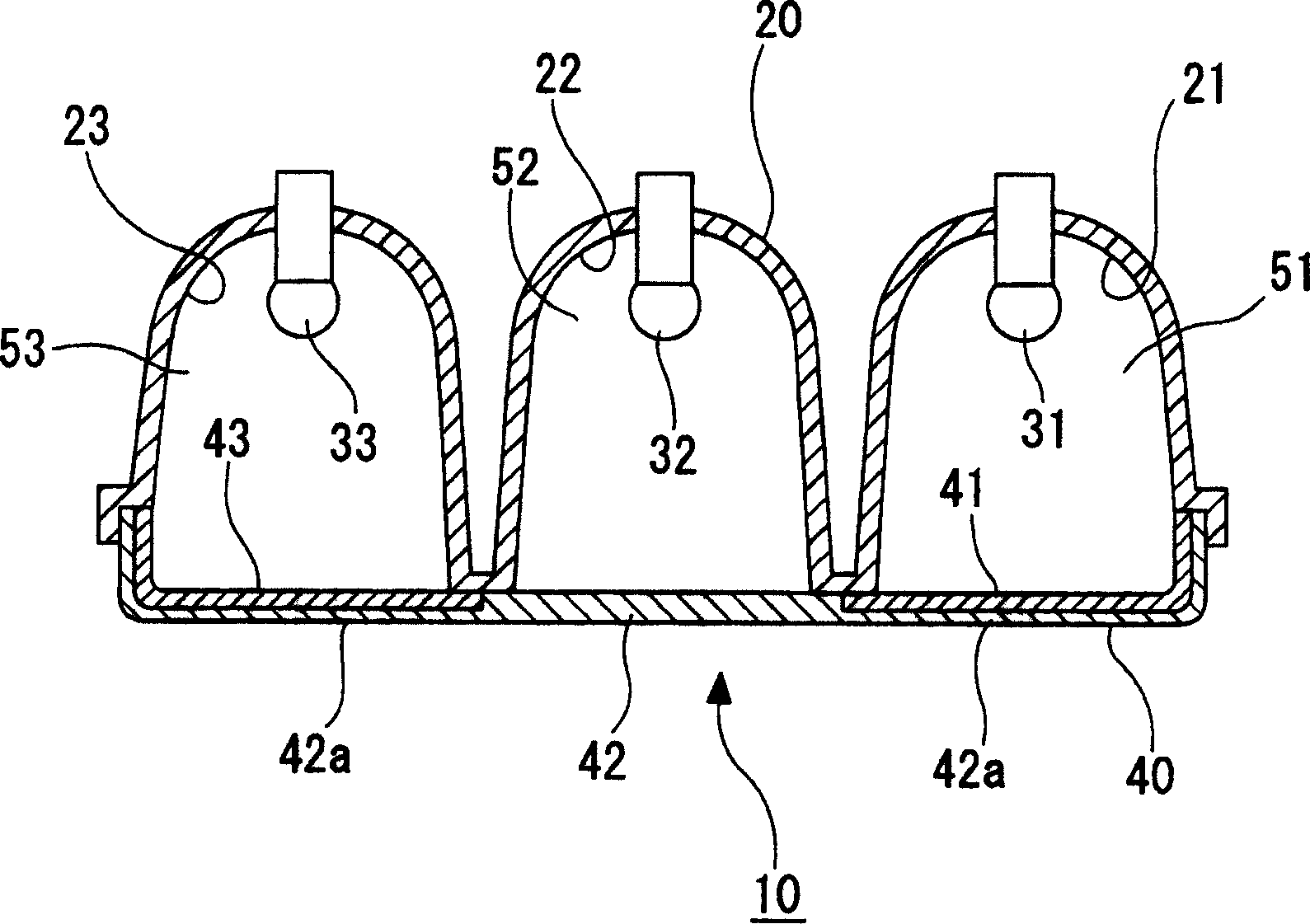

[0031] refer to figure 1 The outline of the vehicle lamp according to the present invention will be described.

[0032] The vehicle lamp 10 has a lamp body 20 in which three recesses 21 , 22 , and 23 opening forward are formed. In addition, light source bulbs 31 , 32 , 33 are disposed in the recesses 21 , 22 , 23 .

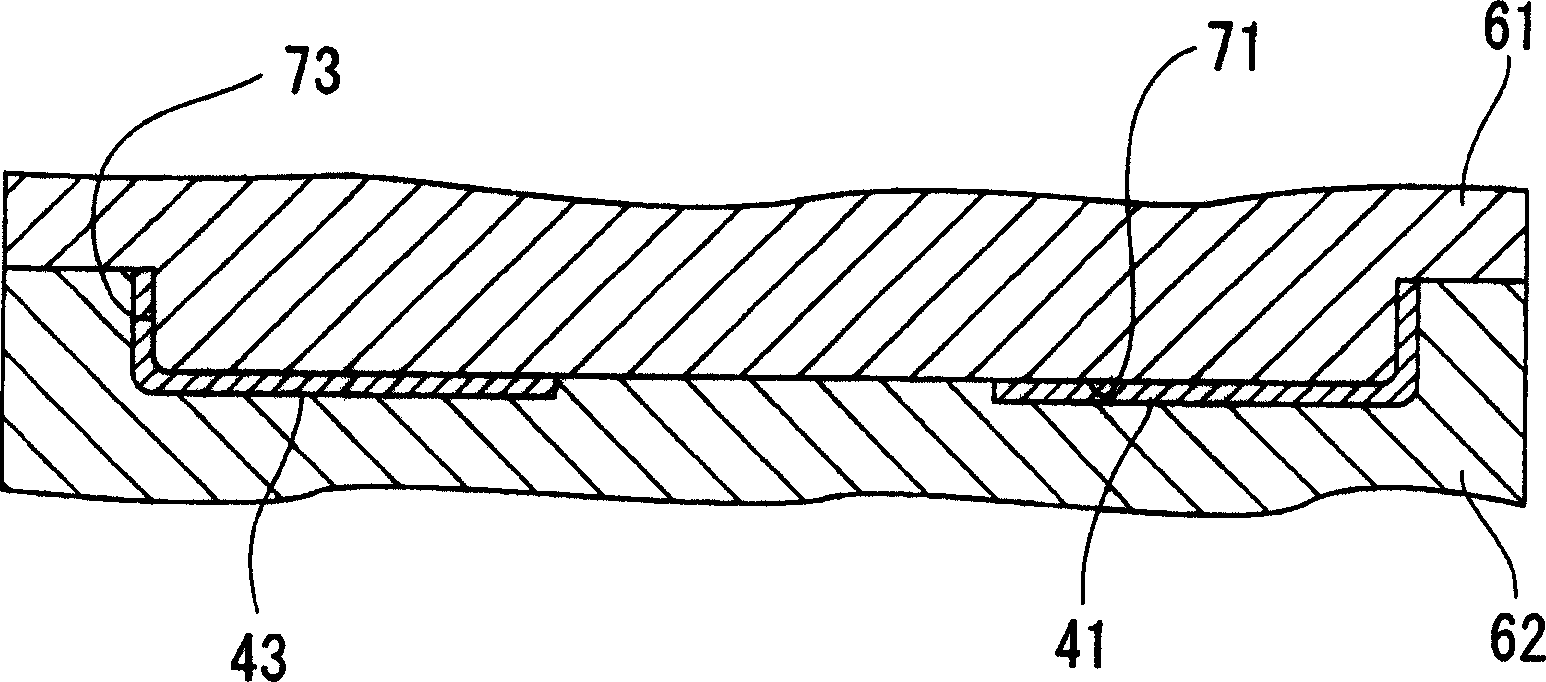

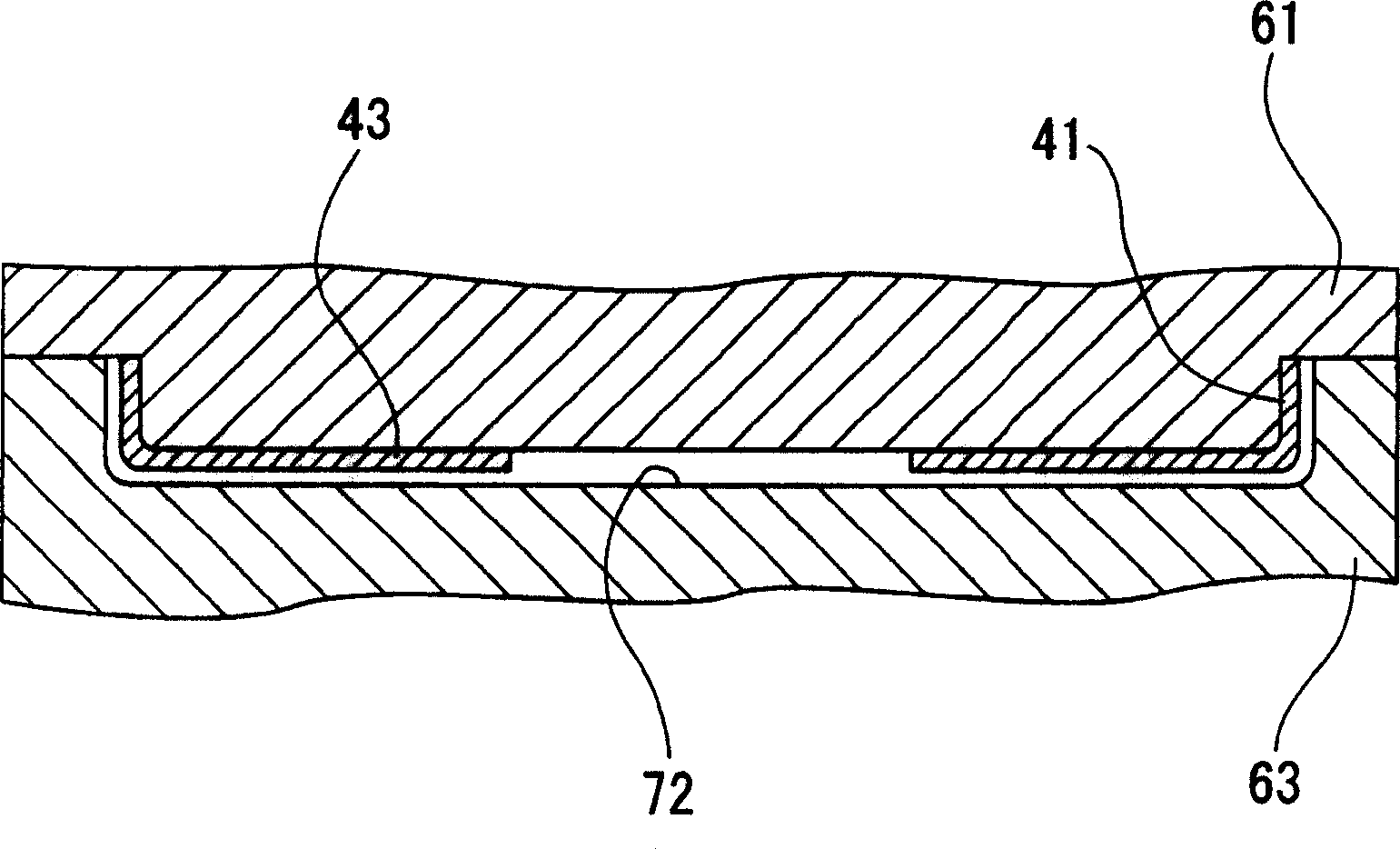

[0033] A light distribution mirror 40 is configured to cover the front of the lamp body 20 and is divided into three lamp chambers 51 , 52 , 53 . Such as figure 1 and Figure 4 As can be seen from the illustration, the light distribution mirror 40 is formed by integrally forming three plastic molding parts 41 , 42 , 43 . The plastic molded part 41 is made of red plastic, the plastic molded part 42 is made of colorless plastic, and the plastic molded part 43 is made of amber plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com