Electromagnetic relay with spring pushing structure

An electromagnetic relay, push block technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve problems such as high cycle fatigue, and achieve the effect of solving dynamic spring fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

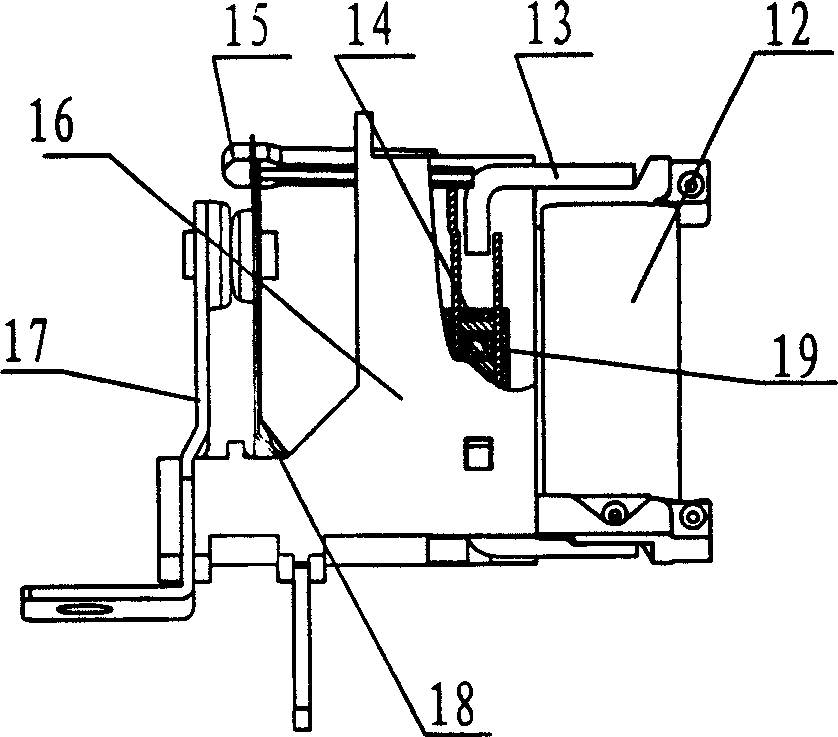

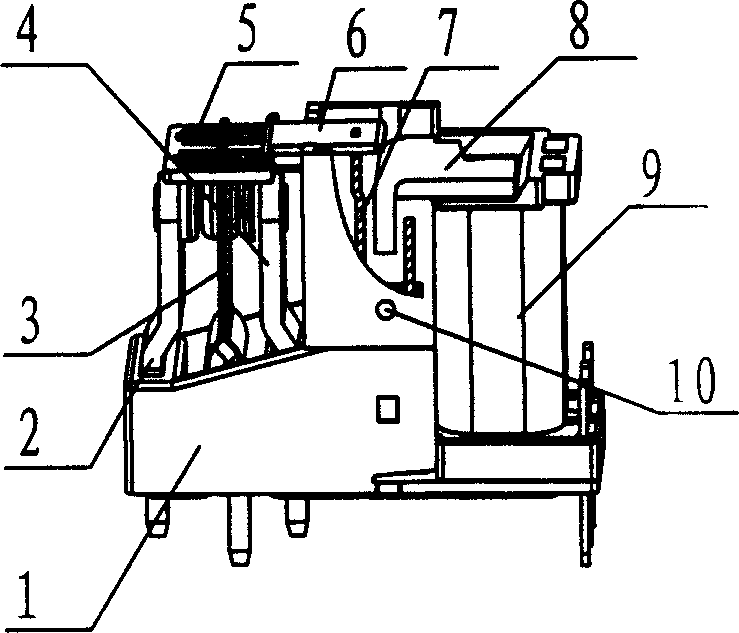

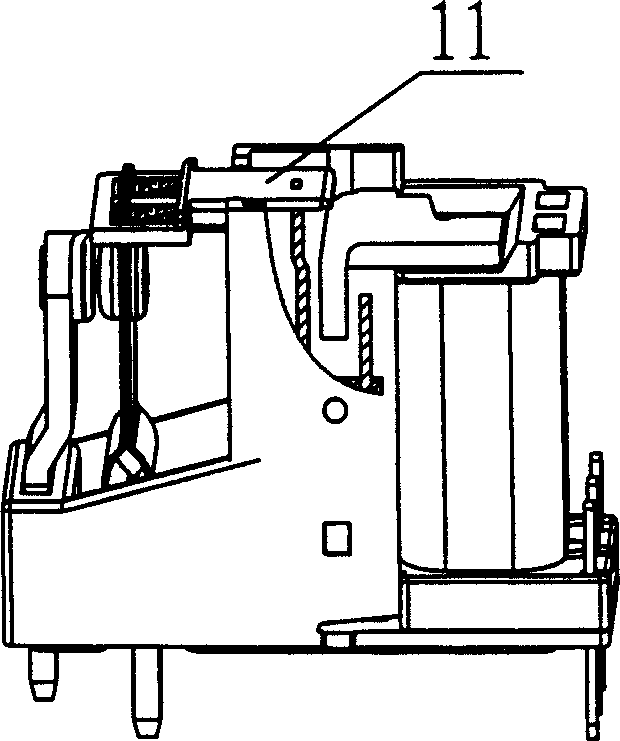

[0019] Such as figure 2 As shown, the present invention (single pole double throw type) consists of a base part, an intermediate mechanism, a magnetic circuit part and a housing. Among them: the base part is assembled by the upper static spring combination 2, the lower static spring combination 4 and the moving spring combination 3 directly inserted into the base 1; the intermediate mechanism is composed of a push block 6 and a spring 5; the magnetic circuit part is composed of a coil 9 , the yoke 8 and the armature combination 7, the coil and the yoke are positioned on the positioning groove of the base by the yoke after being inserted into each other, and the armature combination is positioned on the axis hole of the base by the rotating shaft in the center; the intermediate mechanism is connected by a spring and The combined connection of the movable spring is combined with the armature through the card slot of the part of the pull rod structure under the push block. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com